4-20 DA80F/DA95F AddressRight™ Printers Service Manual (SV61962 Rev. A)

4 • Troubleshooting/Diagnostics

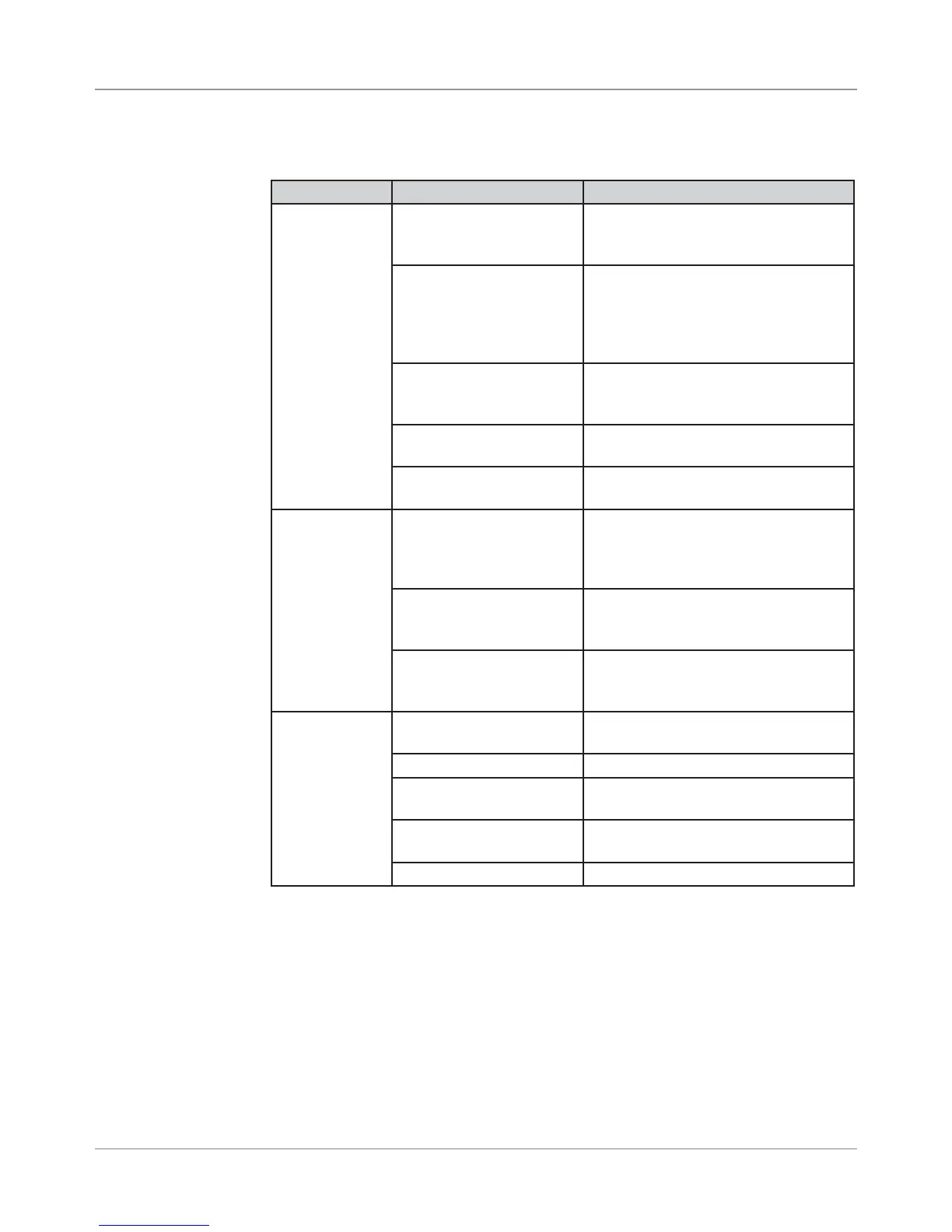

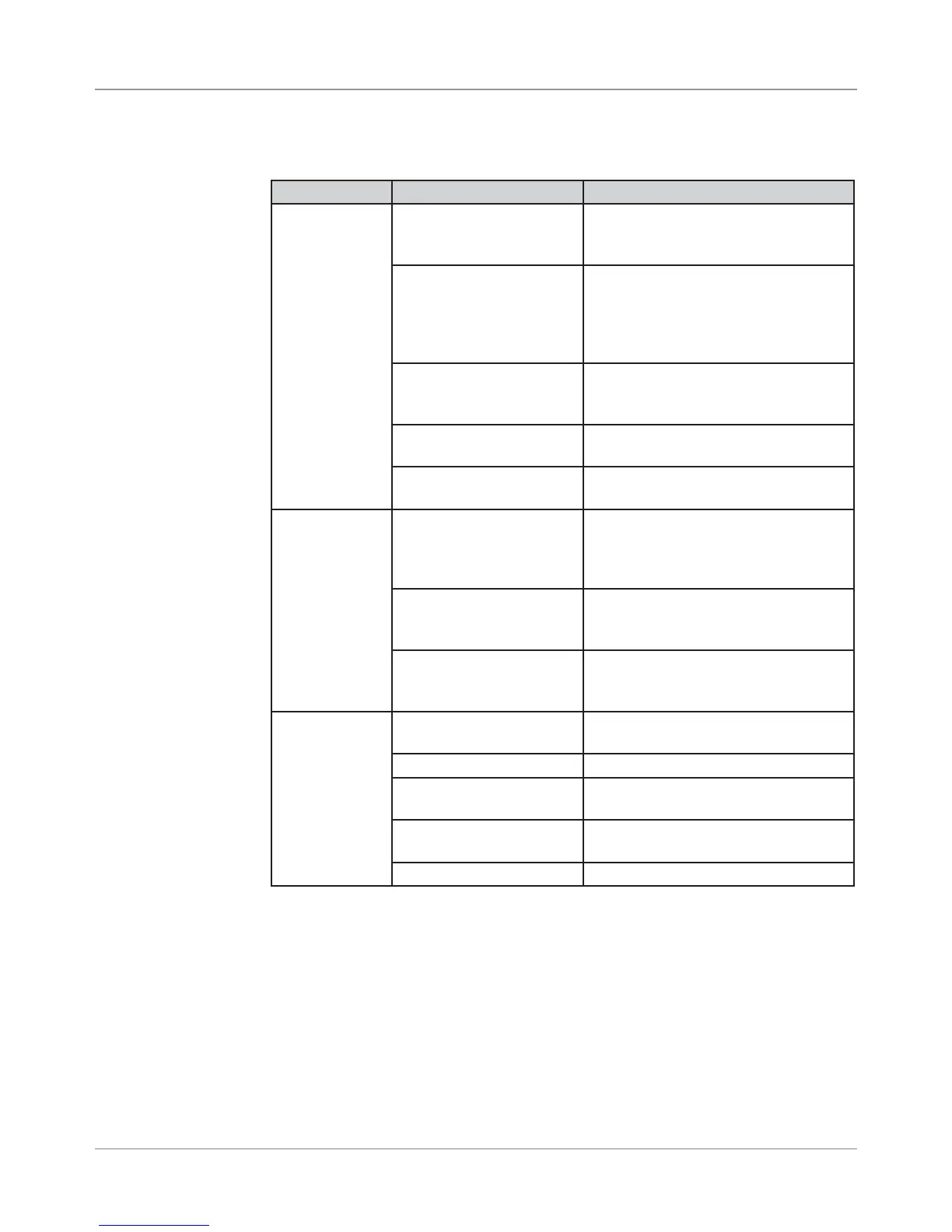

Symptom Possible Cause Solution

Print is Skewed Feeder ramp not set cor-

rectly

Adjust ramp so it is centered with

respect to material (see standard

printer setup on page 4-1)

Side guides not set cor-

rectly

Adjust fence to within 1/16” of mate-

rial. Check that fence is square

with respect to material (assuming

material is rectangle). See standard

printer setup on page 4-1.

Takeaway Rollers not set

correctly [on DA95F]

Adjust rollers to appropriate tension

and location using thickness adjust-

ment (see Operator Guide)

Check setup of the Entry

Rollers.

Redo the setup of the Entry Rollers

(see Operator Guide).

Roller is running along

the edge of the media

Move print head bank to different

area over media.

Addresses

“walking” to

next piece

Number of lines of ad-

dress varies. No Form

Feed used for address

termination.

Check Line Termination CR-

CR,LF=LF. Address Termination

should be Form Feed.

Incorrect address setup Count carriage returns and line feeds

of address field; should match ad-

dress setup

Thickness and Takeaway

Rollers [on DA95F]

Adjust rollers to appropriate tension

using thickness adjustment (see

Operator Guide)

Ink streaking

on Media

Envelope thickness ad-

justment incorrect

Adjust lever to raise print head

The print cartridge is dirty Clean the cartridge

Print head needs purging Run “Purge Print Head“ from Main

Menu.

Print heads not level to

deck (floor)

Level print heads (see section 6.4 for

WF81 and section 6.5 for WF96)

Exit idler rollers dirty Clean rollers with water to remove ink

4.7 Printing

Issues

Table 4-9 Printing Issues

Loading...

Loading...