Technical Information

117

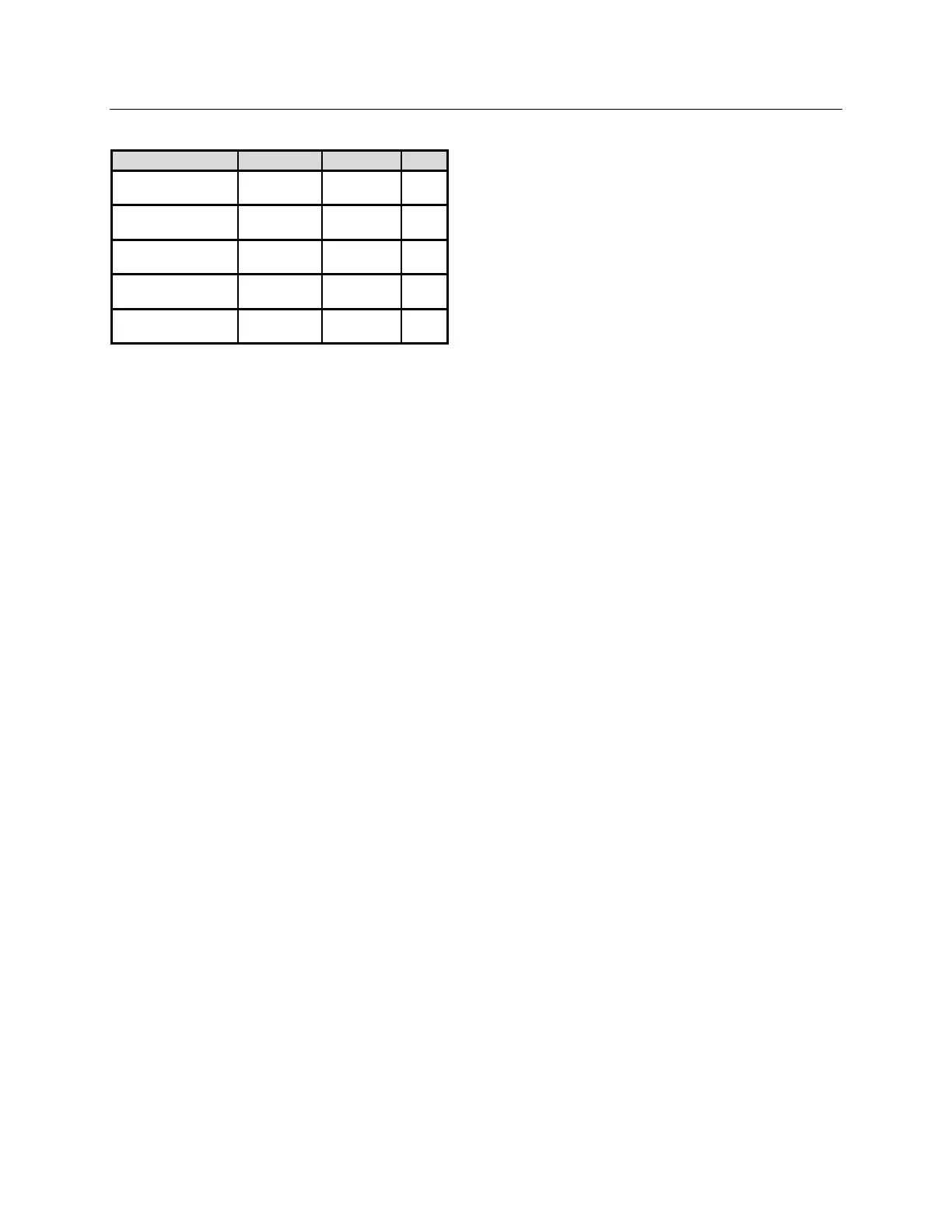

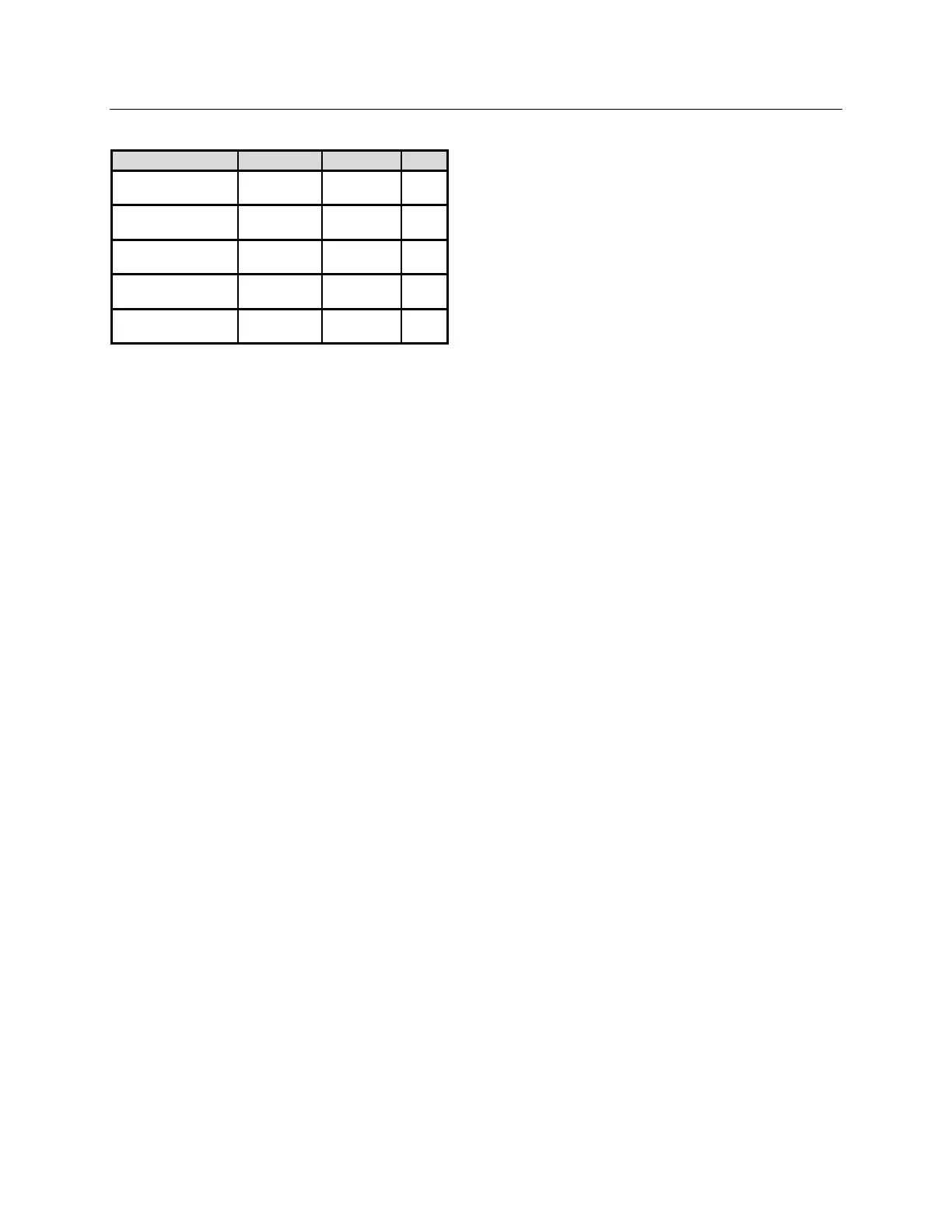

BELTS

Use Make Model Qty

Radiator fan drive

(transfer)

Dayco AX-71 3

Radiator fan drive

(fan)

Dayco

Poly-V

10/55

1

A/C system

compressor

Gates BX-100 2

Alternator 2 x

28V, 140 Amps.

Detroit

Diesel

Poly-V

10/2232

1

Alternator, 1x

“limp-home”

Detroit

Diesel

Poly-V

10/2000

1

ENGINE

Power is provided by a Detroit Diesel DDEC V

Series 60 engine, displacing 12.7 liters. The

engine is an inline six cylinder, four stroke,

turbocharged, air to air charge cooled, diesel

engine with an overhead camshaft and four

valves per cylinder.

Rated H.P. (BASIC) ..........380 HP @ 1,800 rpm

Rated H.P. (STD).... 435 - 445 HP @ 1,800 rpm

Peak torque................. 1,450 lbf-ft @ 1,200 rpm

Operating range .................... 1,200 – 2,100 rpm

TRANSMISSION

ALLISON TRANSMISSION

Allison B500 (B500R with the optional output

retarder) electronically controlled six speed

automatic transmission.

Gear Ratios

1

st

................................................................3.510

2

nd

...............................................................1.906

3

rd

...............................................................1.429

4

th

...............................................................1.000

5

th

...............................................................0.737

6

th

...............................................................0.639

Reverse......................................................4.801

Converter....................................................1.578

Differential ratio ............................................4.30

Differential ratio (optional)............................4.10

Differential ratio (optional)............................4.56

Differential ratio (optional)............................4.88

ZF-ASTRONIC TRANSMISSION

Electronically controlled ten speed automatic

transmission.

Gear Ratios

1

st

.................................................................7.44

2

nd

.................................................................5.78

3

rd

.................................................................4.57

4

th

.................................................................3.55

5

th

.................................................................2.70

6

th

.................................................................2.10

7

th

.................................................................1.63

8

th

.................................................................1.27

9

th

.................................................................1.00

10

th

...............................................................0.78

Reverse......................................................11.41

Differential ratio............................................3.73

Differential ratio (optional)............................3.42

Differential ratio (optional)............................3.58

BRAKES

The features of the braking system include a

dual system where the front and rear circuits are

completely independent from each other. The

brakes are air operated disc type brakes with

automatic slack adjusters on front, drive and tag

axles The emergency/parking brakes are located

on the drive and tag axles only.

BRAKE CHAMBER EFFECTIVE AREA

Front axle ...................................................24 in

2

Drive axle ..........24/24 in

2

(service / emergency)

Tag axle ............14/16 in

2

(service / emergency)

AIR SYSTEM

Compressed air is provided by a 15.8 cfm

Bendix-Westinghouse BA-921 one cylinder,

gear-driven, water-cooled and engine oil

lubricated air compressor.

Other features and components of the air

system include an air dryer and nylon color-

coded air lines.

ANTILOCK BRAKING SYSTEM (ABS)

The antilock braking system has one Electronic

Control Unit (ECU) controlling a four channel

system. A wheel slip sensor is mounted at each

front axle and drive axle wheel. The Tag axle

wheels are slave to the drive axle wheels.

The Electronic Control Module (ECM) is

maintenance free. Its operating voltage is 24 ± 6

volts DC. The thermal operating range for the

ECM is from -40 to 167°F (-40 to 75°C).

Loading...

Loading...