Safety Features and Equipment

89

HYDRAULIC JACK

To raise

: turn release valve clockwise. Insert

handle in socket and raise by pumping.

To lower

: remove handle and turn the release

valve slowly

counterclockwise.

Always keep ram and extension screw retracted

when jack is not in use.

Service

: Check oil level when jack fails to raise

to full height. Lower ram completely with release

valve open and jack in upright position, remove

filler plug and refill to level of filler hole with

hydraulic jack oil. Never use brake fluid

.

DANGER

Jack is intended for lifting only. Do not get

under the vehicle or load for any reason

unless it is properly supported with safety

stands and securely blocked.

DANGER

Do not load jack above rated capacity. Prevent

"side loading", make sure load is centered on

ram. Do not push or tilt load off jack.

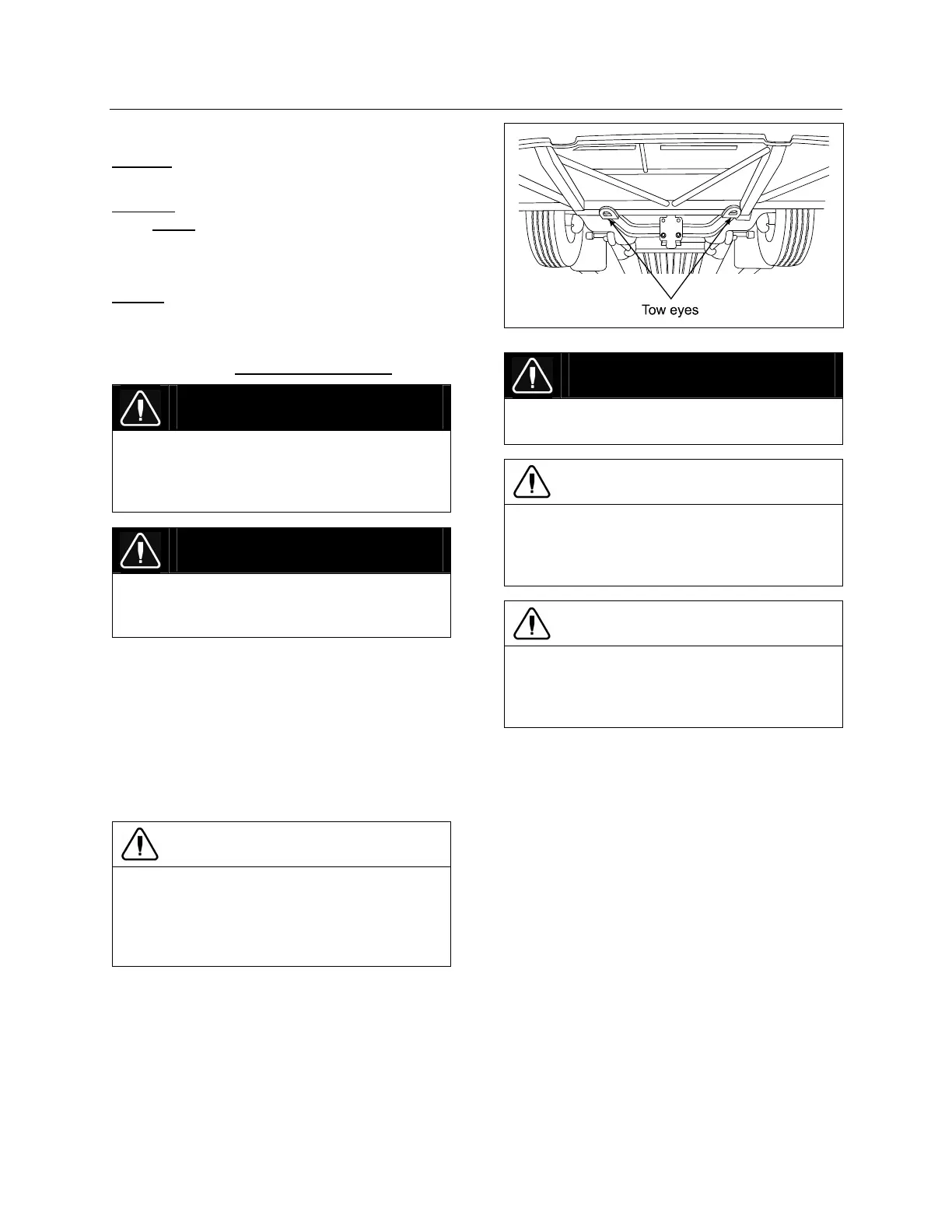

TOWING

To prevent damage to the vehicle, use the two

tow eyes fixed to the vehicle frame between the

front axle and the front bumper. Use only a solid

link tow bar and a safety chain to tow the

vehicle. If required, connect an auxiliary air

supply to the vehicle so the emergency/parking

brakes don’t apply while towing.

CAUTION

To prevent damage to the vehicle structure, it

is not recommended to tow the vehicle from

the rear. In case of damage to the drive train

components, use a low bed semi-trailer to

support the rear end.

TOW EYES UNDER VEHICLE 18401

DANGER

Do not carry passengers while the coach is

being towed.

CAUTION

To prevent damage to the drive train

components, disconnect axle shafts or

driveshaft before towing. Do not attempt to

push or pull-start the coach.

CAUTION

Make sure axle shafts or driveshaft are

installed correctly after towing. Tighten axle

shaft and driveshaft nuts to the correct torque

settings. Do not invert shafts.

EMERGENCY AIR-FILL VALVES

The vehicle is equipped with two air system

emergency fill valves to supplement the air

system when air pressure is low and the engine

cannot be operated. One valve is located inside

the front service compartment. The other valve

is located inside the engine compartment.

Both air system emergency fill valves are fitted

with standard tire valve stems. The air systems

can be filled using any standard external air

supply line. The fill valve located in the engine

compartment supplies air for all systems

(brakes, suspension and accessories). The fill

valve located in the front service compartment

supplies air for accessories only.

Loading...

Loading...