Operation and Maintenance Manual Rev M(ii) 4/03

- 42 -

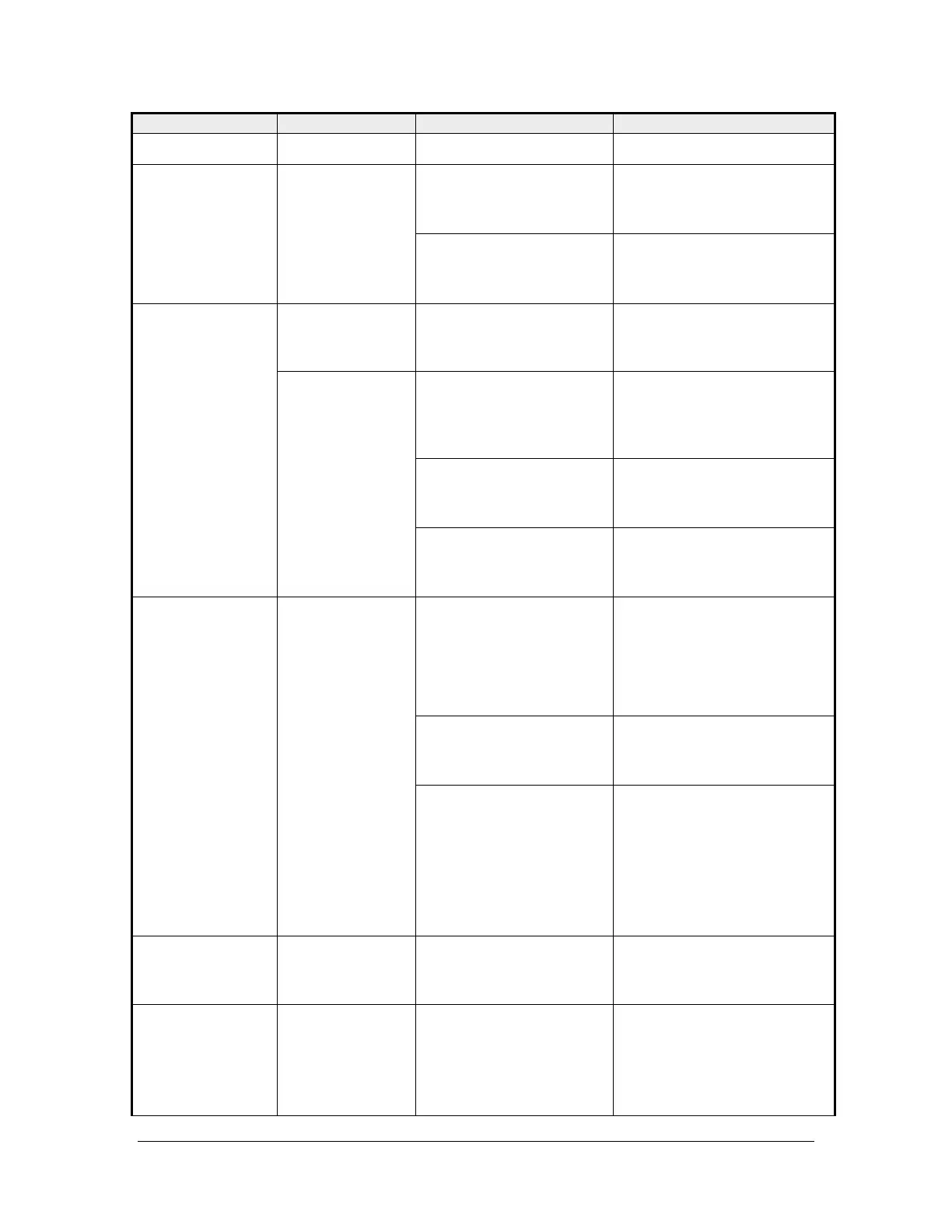

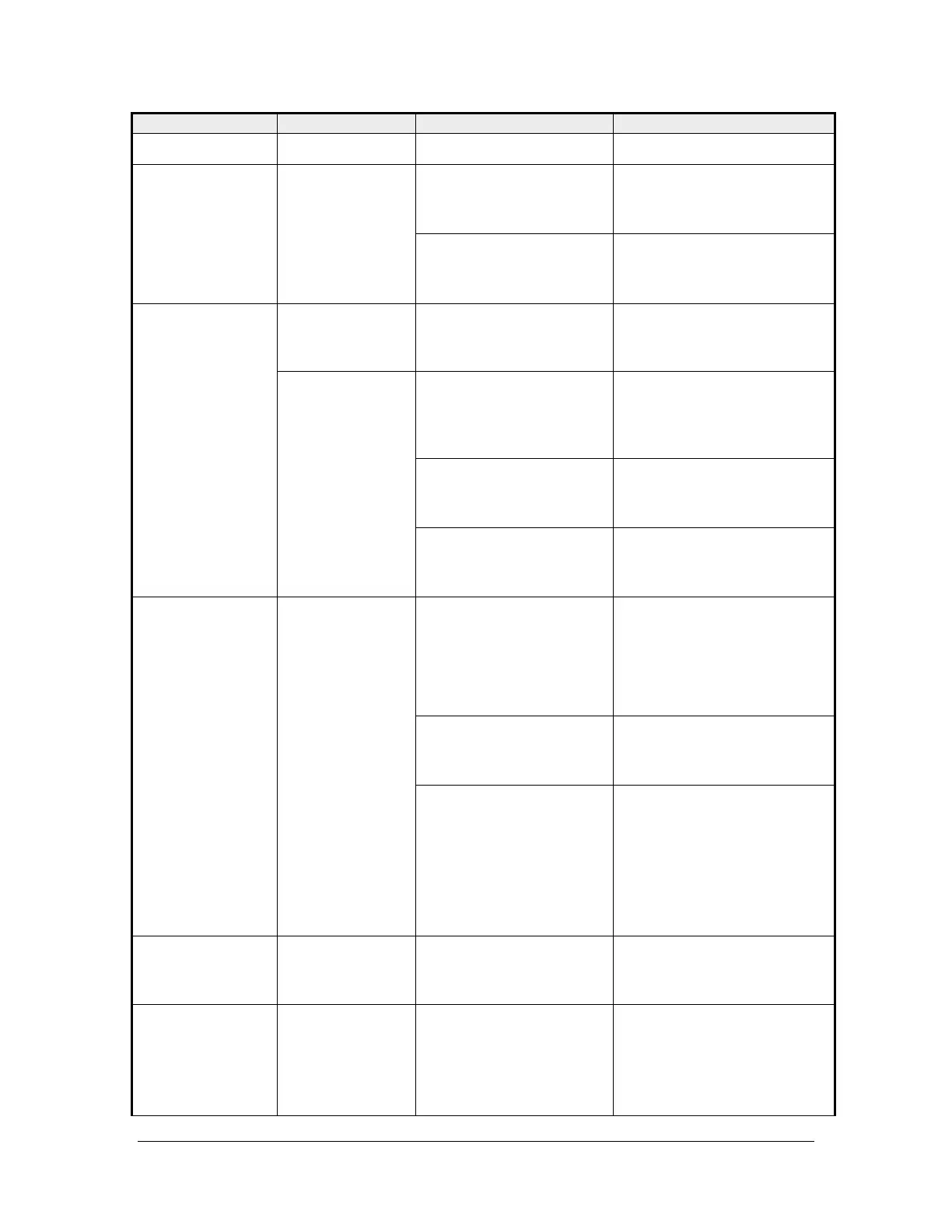

Operation Other Symptoms Possible Cause Corrective Action

on GPIO interface board.

Amp cables are loose or

disconnected

• Check J9 and J11

connections on GPIO

interface board.

Motor Cable(s) are loose or

disconnected

• Verify CPC connections at

motor and terminal

connections on amp.

X, Y or Z axis does

not move.

End effector can be

moved freely when

the power is on.

The EMERGENCY STOP

push button is depressed.

• Release the EMERGENCY

STOP push button.

LCD Screen

indicates that the

system is running

normally.

The amp fuse(s) is blown.

• Check F1-F5 fuses located

on GPIO interface board.

Amp cables are loose or

disconnected

• Check J9, J10 and J11

connections on GPIO

interface board.

Motor Cable(s) are loose or

disconnected

• Verify CPC connections at

motor and terminal

connections on amp.

Axis Looses

position.

The axis speed or

acceleration has been set to

too high.

• Check speed, acceleration

and deceleration settings.

• Refer to Appendix D for

speed, acceleration

deceleration charts.

Coupling is slipping.

• Check coupling connection

at motor and ball screw.

Tighten if needed.

The axis amplifier is bad.

• Replace the amplifier.

Incorrect AC voltage.

• Check the power source

supplied to the workcell.

• Check the power entry

module for correct

configuration.

Pneumatic actuator

failure.

Pneumatics work

slowly.

Air lockout valve on the rear

of the machine is in the OFF

position.

• Turn the lockout valve to

the ON position.

Insufficient air pressure.

• Check and adjust the system

pressures to the correct

values. Please refer to the

Machine Specific

Information section of the

O

eratin

Guide for

Loading...

Loading...