Operation and Maintenance Manual Rev M(ii) 4/03

- 43 -

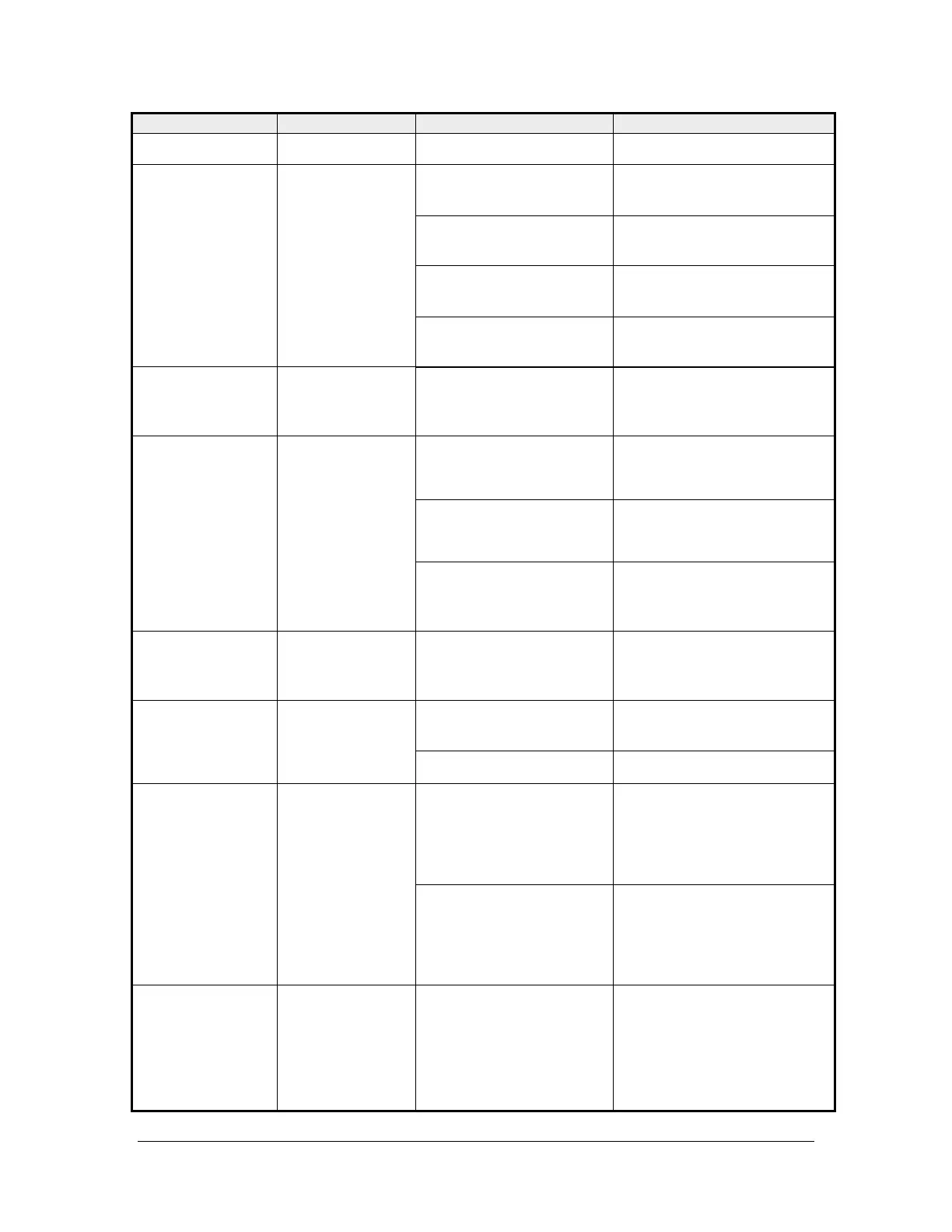

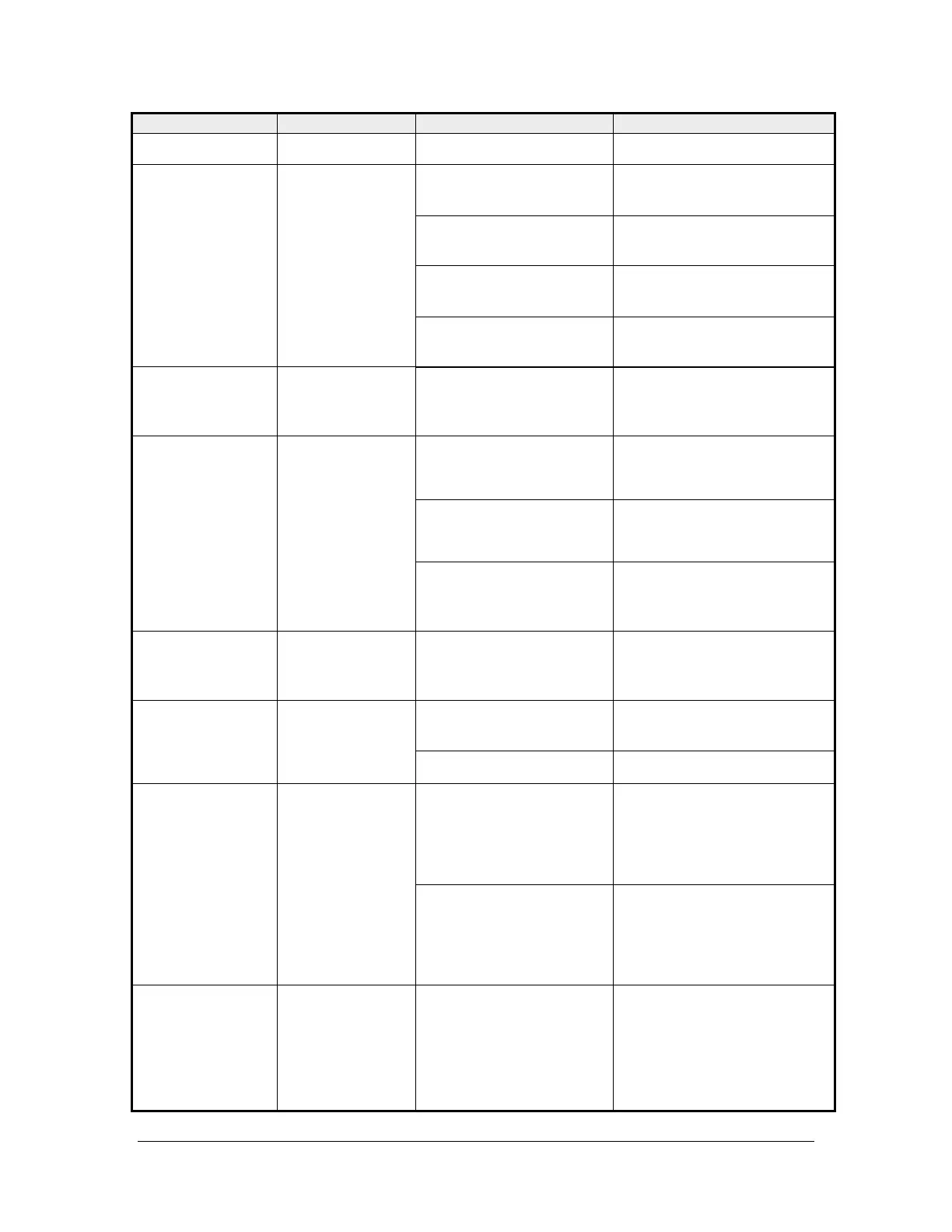

Operation Other Symptoms Possible Cause Corrective Action

particular pressure settings.

Restricted air line.

• Correct any tight bends or

restrictions in the air lines.

Loose Fitting or Tubing

Connection.

• Tighten connection.

Frayed or damaged air line.

• Replace the damaged air

line(s).

Sensor is not positioned

correctly.

• Adjust the sensor location.

Part in place sensor

failure.

Cable is loose or not

connected.

• Check the cable

connections. Correct any

loose connections.

Conveyor does not

run.

Conveyor belt stuck to rails.

• Clean or replace belt.

W axis amp fuse(s) is blown.

• Check F4 fuse located on

GPIO interface board.

Amp cables are loose or

disconnected

• Check J10 and J11

connections on GPIO

interface board.

Motor Cable(s) are loose or

disconnected

• Verify CPC connections at

motor and terminal

connections on amp.

Exhaust fan does

not run.

No air flow. The motor overload relay,

OL-1, is in the tripped state.

• Reset the exhaust fan

overload relay.

•

The exhaust fan

overload relay trips

frequently.

Excessive motor

heating.

Insufficient air

flow.

Blocked exhaust filter leads

to excessive motor heating.

The overload relay trips.

• Clean the air filter on the

exhaust intake.

• Reset the exhaust fan

overload relay.

Insufficient air flow capacity

in the factory ducting.

• Upgrade the duct to allow

for more air flow.

• Reset the exhaust fan

overload relay.

The filter and

ducting are fine.

The motor

temperature is

normal.

The overload relay current

setting has been changed.

• Verify the current setting on

the overload relay. Please

refer to exhaust fan setup.

• Checked the tripped flag on

the overload relay. Push the

reset button to reset the

Loading...

Loading...