CHAPTER 3

20 Hawkeye Nozzle Control Operation Manual

c. Vacuum pressure is less than 11.5” of mercury [29 cm of mercury].

NOTE: The vacuum switch on the pump will engage and a flow alarm will display if the product cannot be

drawn into the pump (e/g vacuum pressure at or above 11.5” of mercury [29 cm of mercury]. Check

screens, chemical tank lids, hose diameter and any hand valves between the chemical tank and pump

inlet. Also, verify that the product is flowing freely. Cold temperatures and high viscosity products may

cause high vacuum pressures and cause the pump to not operate properly.

5. Touch the Sidekick Pro ICD Menu button for the desired pump product number.

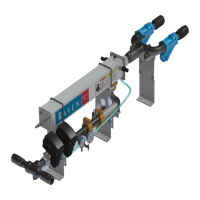

FIGURE 11. Sidekick Pro ICD Menu Button

6. Select the Diagnostics Information tab.

FIGURE 12. Diagnostics Information Tab

7. Select the Prime Pump button to initiate the pump priming sequence. Allow the pump to prime. The priming

procedure will run until the controller detects the pump is primed. If the pump is unable to prime, the console

will end the priming procedure after two minutes and display an error.

FIGURE 13. Prime Pump Button

NOTE: If the console displays an error message during the priming process, verify that the conditions listed

in step 4 exist. Press the Stop softkey at any time to stop the priming procedure. If the pump fails to

prime after the first attempt, restart the priming procedure. If the pump is still unable to prime

successfully, check the system for leaks, verify the valves are turned on, and verify the hoses are filled

with product. It may be necessary to recalibrate the pressure transducer.

PUMP CALIBRATION

Prior to starting a chemical injection application, verify the pump is calibrated and operational.

1. Ensure that the pump is primed.

2. Set the hand valve on the injection pump outlet to recirculate the product back to the supply tank.

3. Remove the cover from the injection pump calibrator.

4. Press the calibrator all the way down and gently replace the calibrator cover.

Loading...

Loading...