81

b)Fineadjustmentofthelamentinfeed

Thischapterdescribeshowtoadjustthelamentfeedprecisely,e.g.tocompensateforthetoleranceofthefeedknurl.Inourexample,theleft

lamentfeediscalibrated.

Preparation

• Ifithasnotbeendoneyet,installthesoftwareRepetier-Hostincl.thedriversandconnecttheprintertothecomputer(seechapter"12.Soft-

wareandrmwareInstallation").

• Ifapplicable,entertheCOMportandconnectthesoftwaretotheprinter(seechapter"18.a)Connectionoftheconnectedprinter").The

symbol at the upper left must be green and it must say "Disconnect" below.

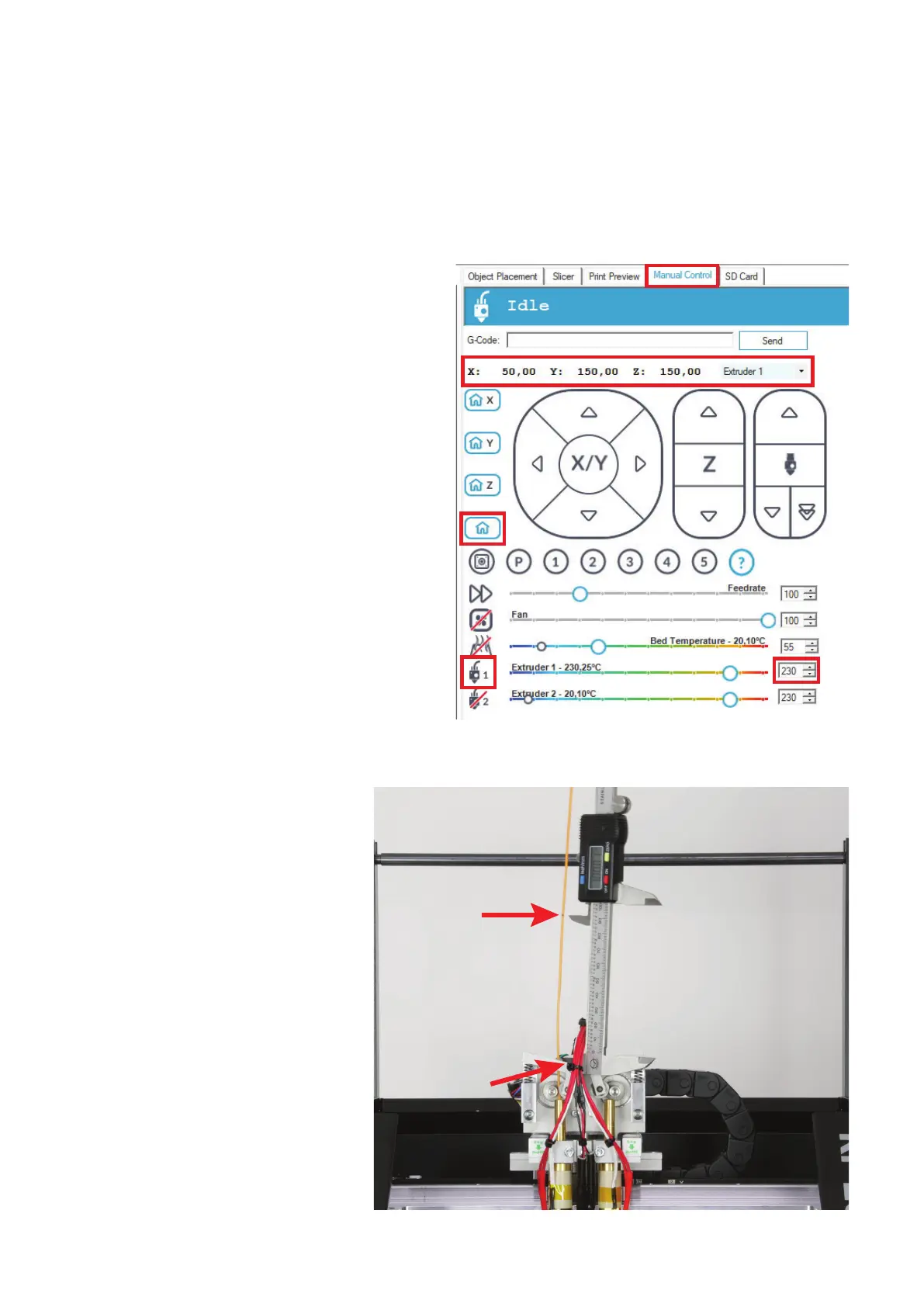

• Whentheprinterisconnected,switchto"Manual Control" in the

software.

The printer must only be controlled via the software throughout this

process.

• Moveallaxistothehomeposition.Forthis,clickthehouseiconin

the middle.

• UsethearrowsX/YandZtomovetheprintingplateandtheex-

truder carriage roughly to the position indicated in the large red

box. This is about making the extruder accessible easily and ena-

blingthelamenttoexittheextruderwell.

• Heatuptheextruder1(leftextruder/extruder0inthermware)to

printingtemperatureandinsertalament.Thenletitextrudealittle

lament.Inourexample,weuseconventionalPLAandtherefore

have chosen a temperature of 230 °C.

Measuring the feed

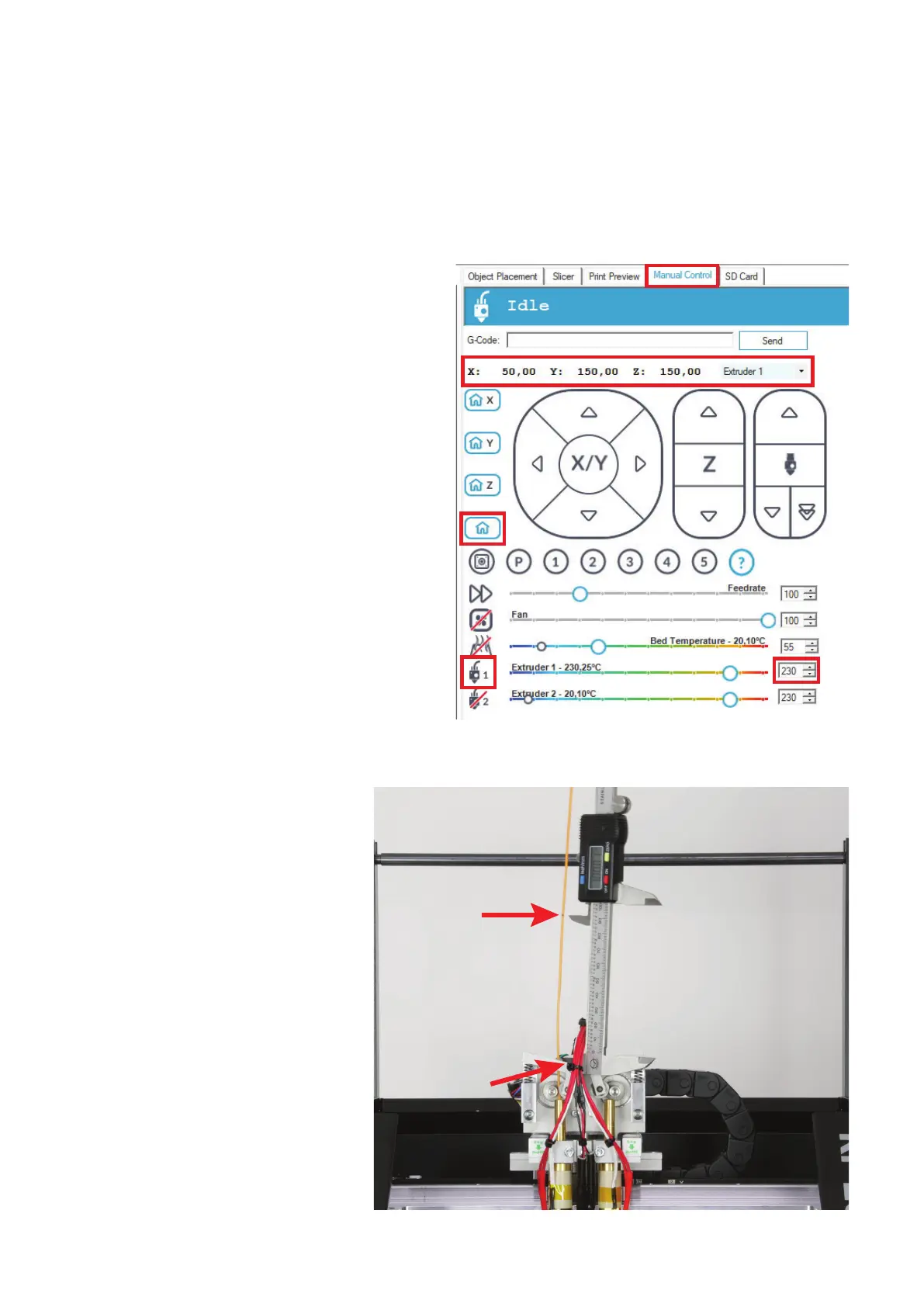

• Mark100mmor10cmpreciselyattheinsertedla-

ment, starting at the upper edge of the ball bearing.

• Alwaysapplythemeasureontheinsideasshown

inthegure.Thispreventstheballbearingholder

from being pushed down. When you measure the

right side later, apply your measure to the left side

ofthelament.

Loading...

Loading...