Beijing RichAuto S&T Co., Ltd.

Forging ahead and determined to win 19

and reduce the operating speed of the entire graph. System default:linear acceleration is 800 mm/s

2

,

curve acceleration is 1000 mm/s

2

, the proposed curve acceleration is 1-1.5 times the linear

acceleration value.

6. Start Speed Unit:mm/minute

The speed of axis started directly from standstill. Not starting from zero speed, but starting

directly from a certain speed,so it can shorten the overall processing time,but do not set this speed

too high. Set too high, it will cause the motor losing steps, jitter and even whistle;Set too small, it

will reduce the operating speed of the entire graph. If the inertia of motion axes (axis heavier),

users can set a smaller start speed, if the inertia of motion axes smaller (lighter shaft), users can set

it bigger.

7. Voltage Setup

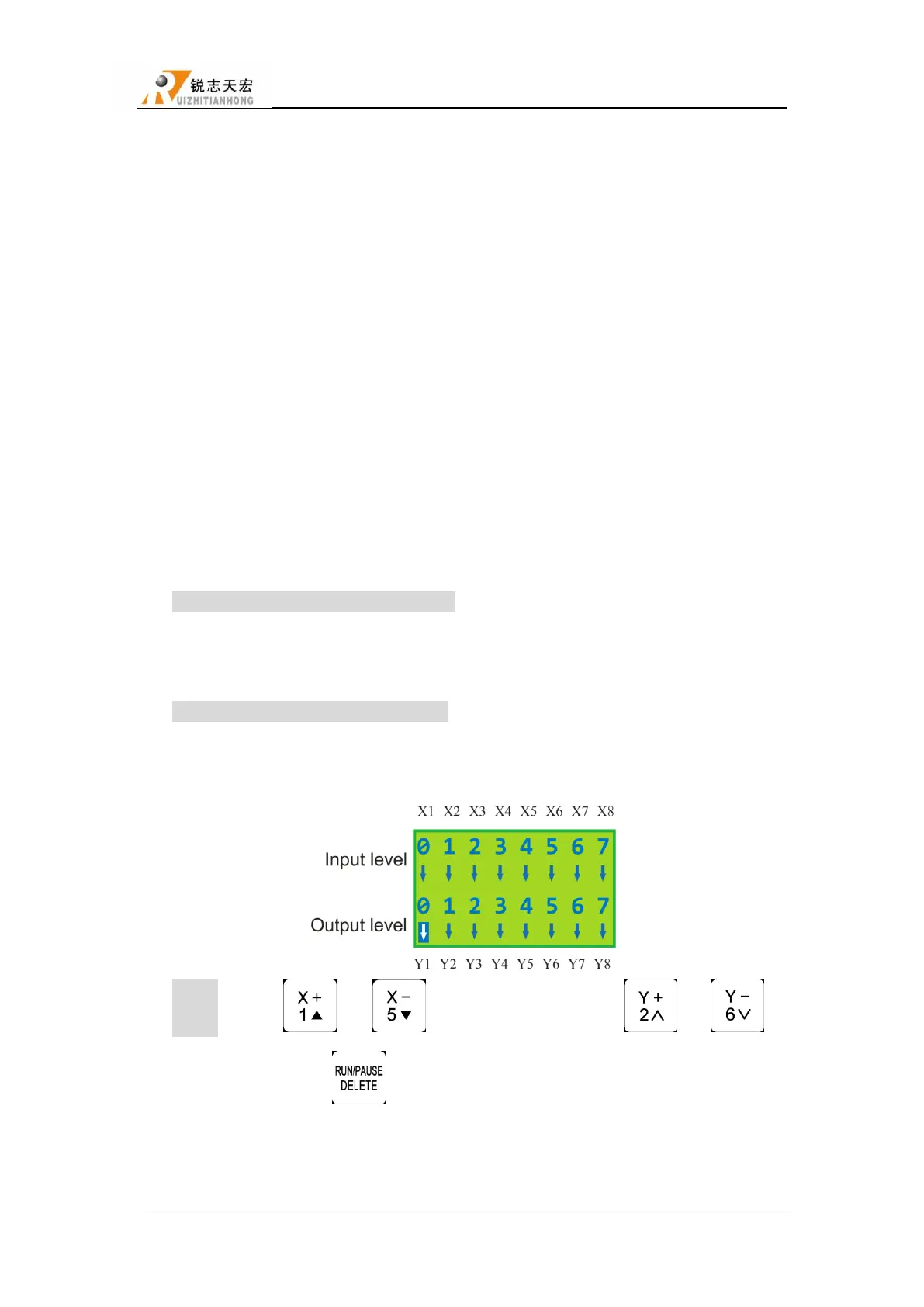

Set input and output signal terminal status,―↓‖ means normal open,―↑‖ means normal

closed.Including two rows of arrow:

The upper arrow indicates the input level:Set input signal level.The top four: 0 ,1 ,2 ,3

positions correspond X ,Y ,Z axis back home ,toolsetting signal;4-7: driver alarm ,hard

limit ,E-stop signal,pedal switch.

The under arrow indicates the output level:Set output signal level. The top four: 0、1、2、3

positions correspond spindleOn/Off、multi-speed 1、multi-speed 2、multi-speed 3 signal,5、

6:4、5 positions correspond alarm indicator、work indicator signal.

Setting:Press“ ”/“ ” to move around,Press “ ”、“ ‖to

move up and down,press“ ” to change the direction of the arrow.

8. C.A.D.(Tool sensor) Thickness Unit:mm

This thickness should input by actual,if it is bigger than the actual thickness ,Z axis may cut

Loading...

Loading...