Beijing RichAuto S&T Co., Ltd.

Forging ahead and determined to win 61

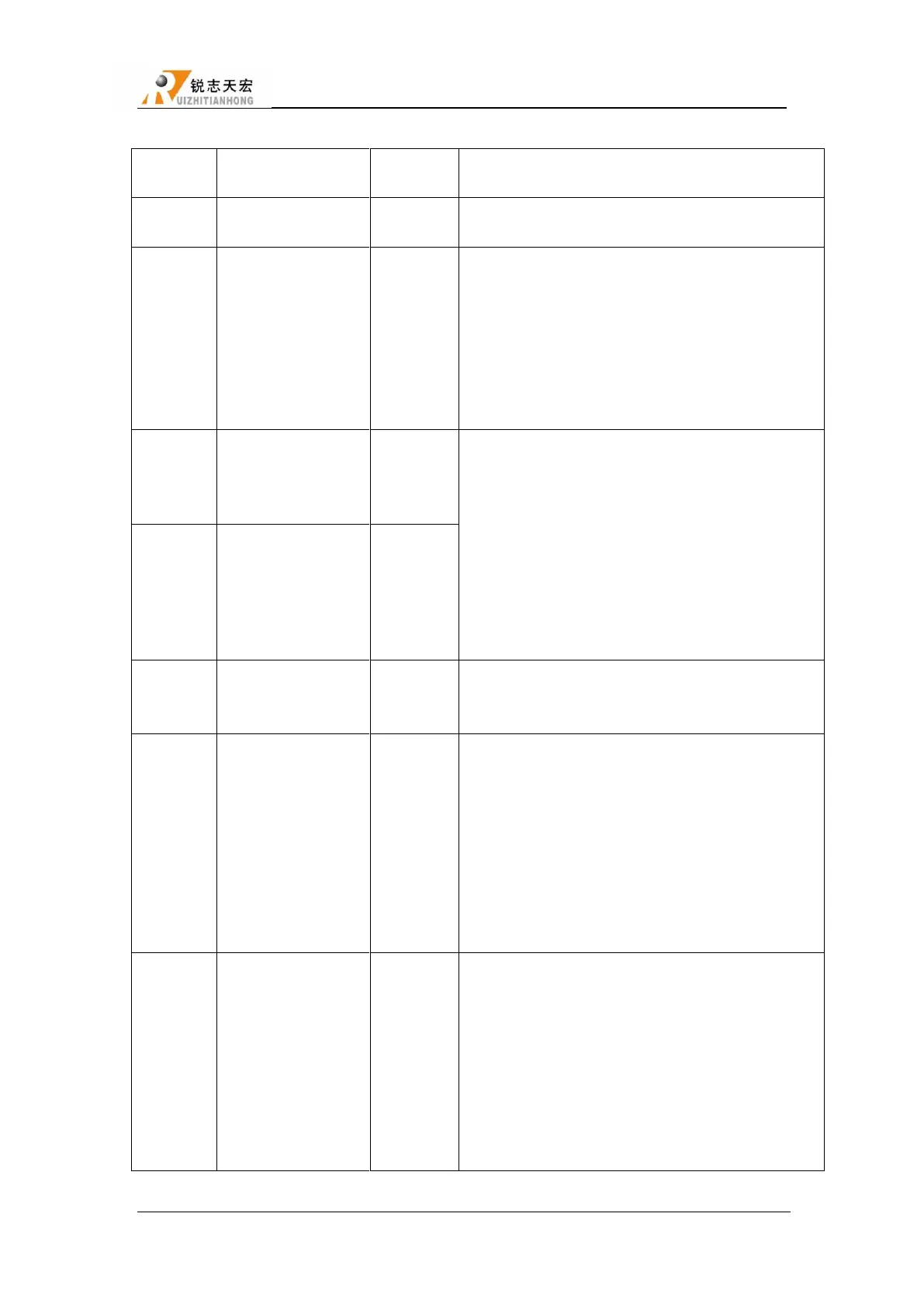

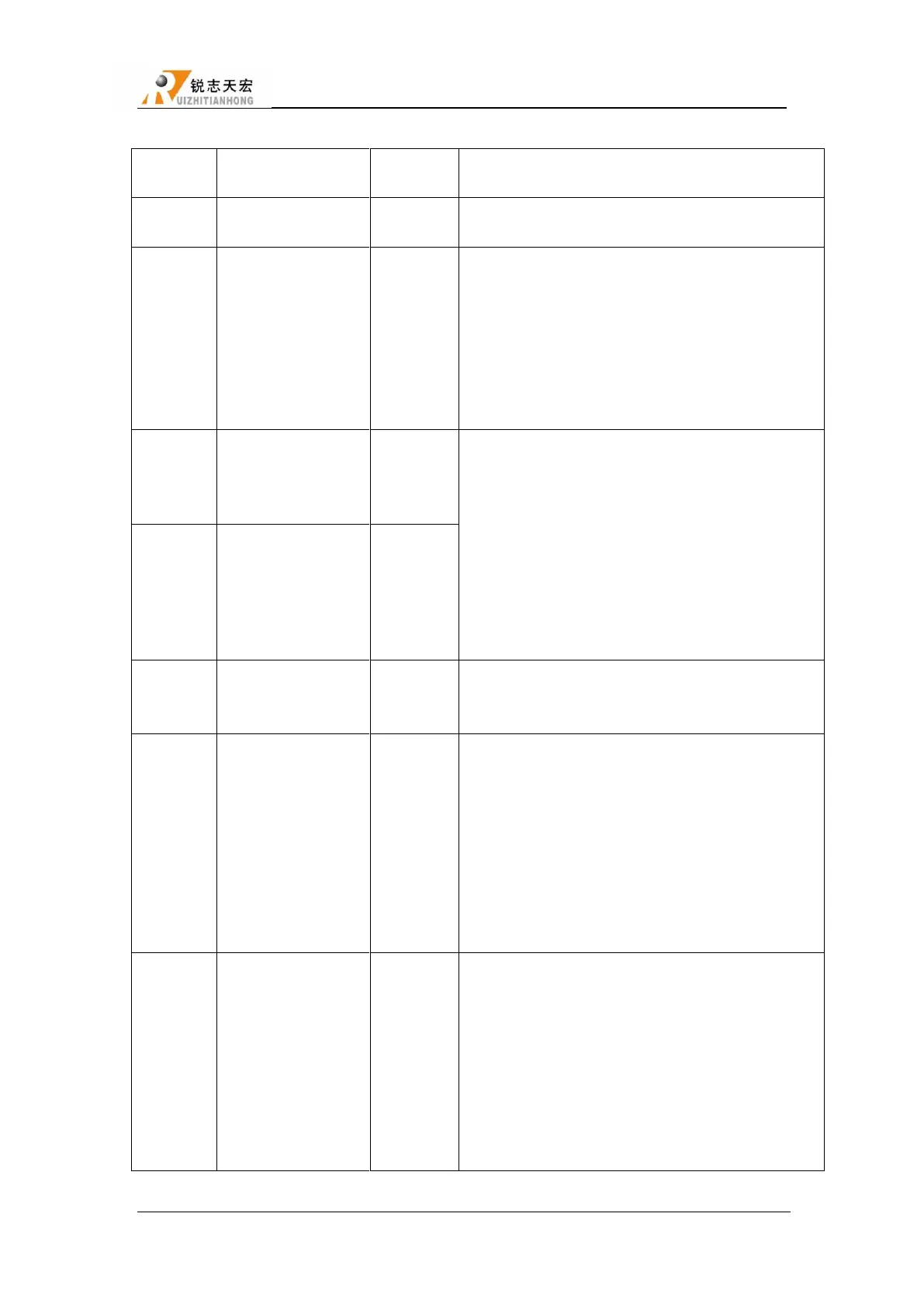

2.Parameter setting

External pulse train

input type

Bit 0:2--pulse+direction

Bit 2:1--negative logic

Bit 3:Maintaining the set value.Since switching

control mode is not used,bit 3--0.

Bit 2:0--forward rotation(CCW)(from the view of

load)

Bit 1,0:00--position control mode

Electronic gear

ratio(numerator)(Z1)

Range:1~32767;

Z1 =Encoder pulses×4;

Z2 =Pulse equivalent×Screw pitch×Transmission

ratio

e.g. Pulse equivalent 1000,Screw pitch 10mm,

encoder pulses 40000,Transmission ratio 1

Pn1-44/Pn1-45=40000×4/1000×10×1=160000/10000

=16/1

Electronic gear

ratio(denominator)

(Z2)

Function setting for

digital input pin DI1

Bit 0:Set 1,servo on all the time.

Function setting for

digital output pin

DO1

DO1 corresponds to pin-6 & pin-7,used as

clamping-position brake signal of Z-axis

Bit1,0:08--set pin-6 and pin-7 as BK- and BK+

repectively.

Bit2 : 0--set DO15 output as normally closed

b-contact point

Function setting for

digital output pin

DO5

DO5 corresponds to pin-28 & pin-27,used as servo

alarm signal

Bit1,0:07--set pin-28 and pin-27 as ALRM+ and

ALRM- repectively.

Bit2:0--set DO5 output as normally closed b-contact

point

Loading...

Loading...