MECHANISM OVERVIEW 31 October 2001

6-4

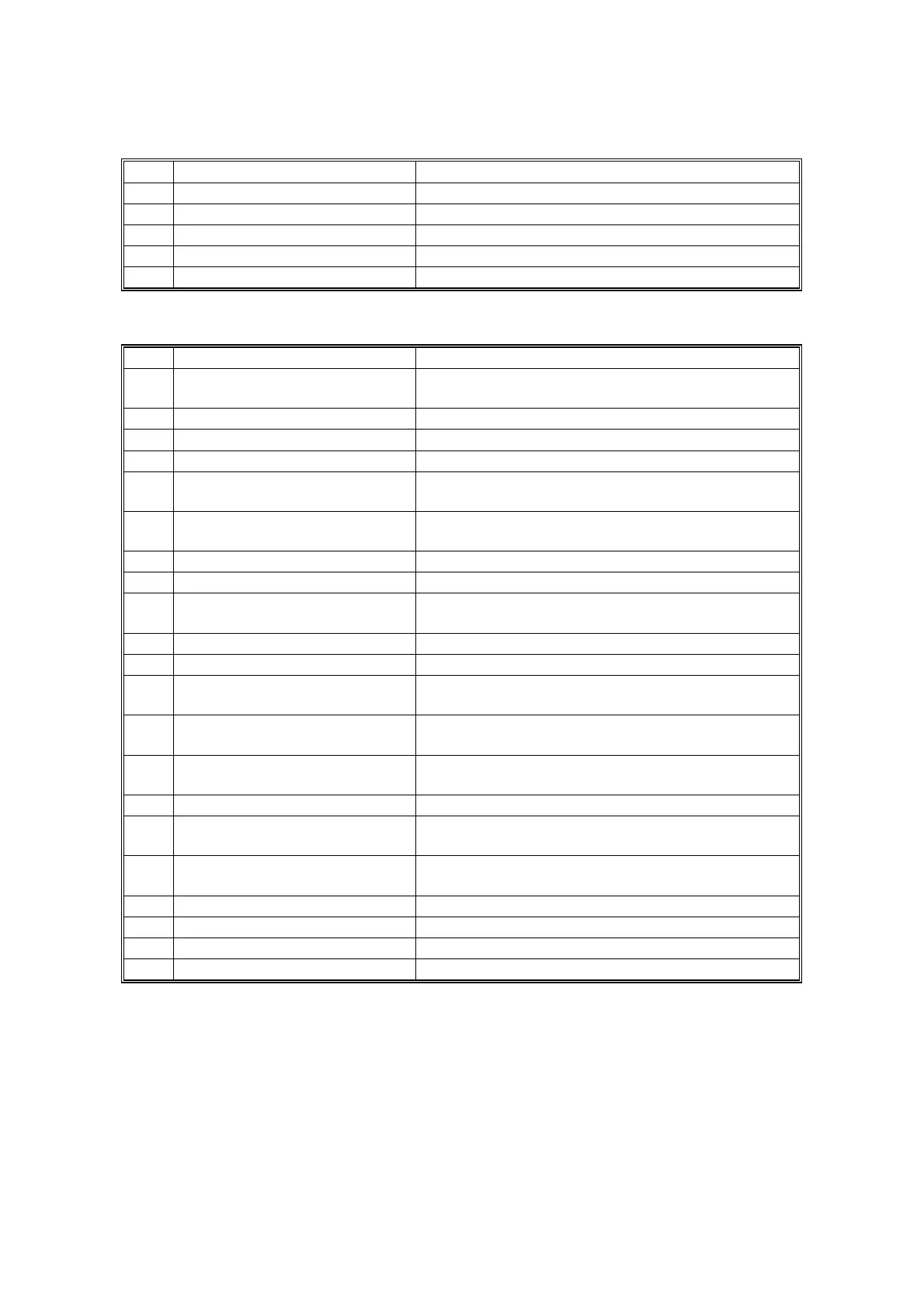

Switches

No. Component Function

19 Table Lowering Switch Lowers the paper table.

24 Door Safety Switch Checks whether the front door is properly closed.

27 Main Switch Turns the power on or off.

13 Master Making Unit Set Switch Checks if the master making unit is installed.

37 Eject Box Set Switch Checks if the master eject box is installed.

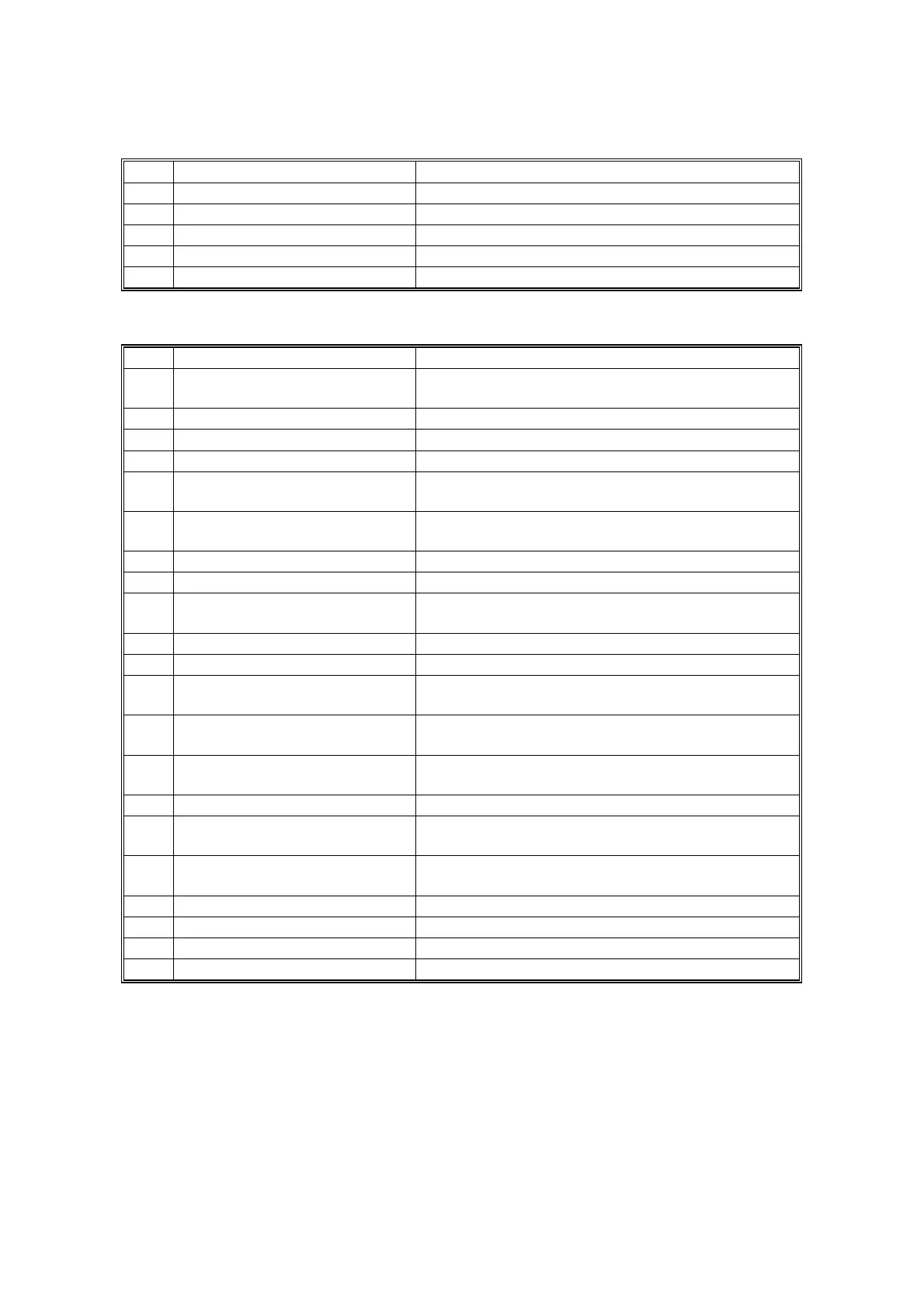

Sensors

No. Component Function

53

Master Eject Position (Drum

HP) Sensor

Detects when the drum is at the master eject

position.

54 Paper Exit Timing Sensor Determines the paper exit misfeed check timing.

52 Feed Start Timing Sensor Determines the paper feed start timing.

30 Master Eject Sensor Detects used master misfeeds.

32

Pressure Plate Limit Sensor

Detects when the pressure plate is in the lowest

position.

31

Pressure Plate HP Sensor Detects when the pressure plate is at the home

position.

34 Drum Master Sensor Detects if there is a master on the drum.

38 Paper Exit Sensor Detects paper misfeeds at the exit.

55

2nd Feed Timing Sensor Determines the paper misfeed check timing at the

paper registration area.

44 Clamper Open Sensor Detects if the clamper is in the open position.

45 Clamper Closed Sensor Detects if the clamper is in the closed position.

49

Table Lower Sensor Detects when the paper table is at its lower limit

position.

2

Platen Cover Sensor Detects whether the platen cover is open or

closed.

1

Scanner HP Sensor Detects when the image sensor is at home

position.

9 Master Set Cover Sensor Checks if the master set cover is properly set.

10

Master End Sensor

Detects when the master making unit runs out of

master roll.

14

Paper Height Sensor Detects when the paper table reaches the paper

feed position.

18 Registration Sensor Detects paper approaching the registration roller.

17 Paper End Sensor Detects when the paper table runs out of paper.

6 Cutter HP Sensor Detects when the cutter is at the home position.

16 Paper Length Sensor Detects when long paper is on the paper table.

Loading...

Loading...