31 October 2001 MASTER EJECT UNIT

6-7

Detailed

Descriptions

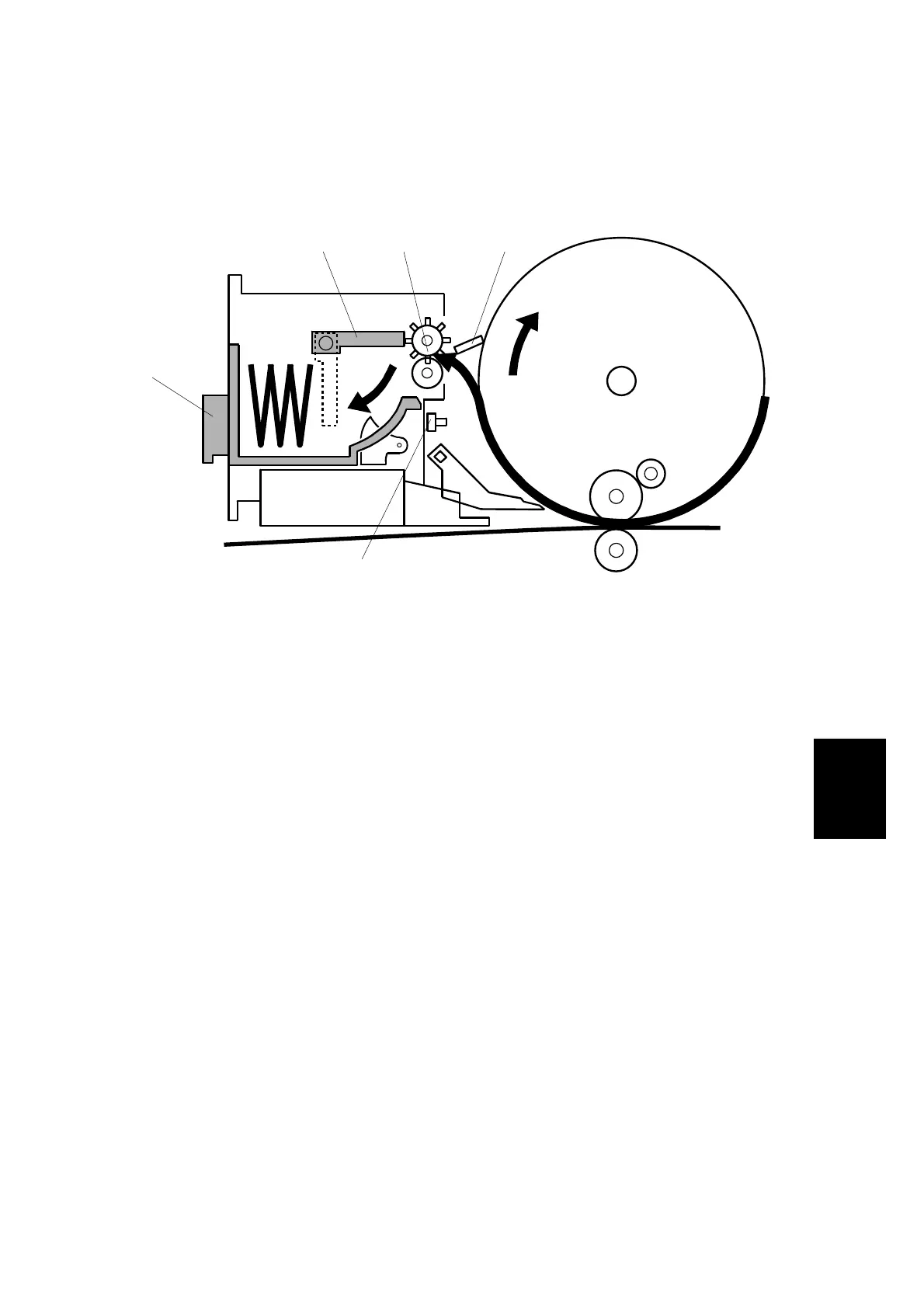

6.2 MASTER EJECT UNIT

6.2.1 OVERVIEW

Overview

The master eject unit removes the used master from the drum. (☛ !: Digital

Duplicators – Duplicating Process – Master Ejecting)

Procedure

The drum turns to the master eject position. Then the clamper [A] opens.

↓

Master eject rollers [B] pick-up the master’s leading edge and feed the master for

1.0 s into the master eject box [C].

↓

The clamper then closes.

↓

The drum then turns at 30 rpm while the master eject rollers continue to feed the

used master into the eject box.

↓

The drum stops after making about 1.5 turns. The master eject motor also stops.

The pressure plate [D] then compresses the used masters in the eject box.

• The capacity is 50 used masters (under normal conditions)

• The master eject process is skipped when the drum master sensor [E] detects no

master on the drum.

C238D022.WMF

[A][B][D]

[C]

[E]

Loading...

Loading...