SPIROR HP - DR

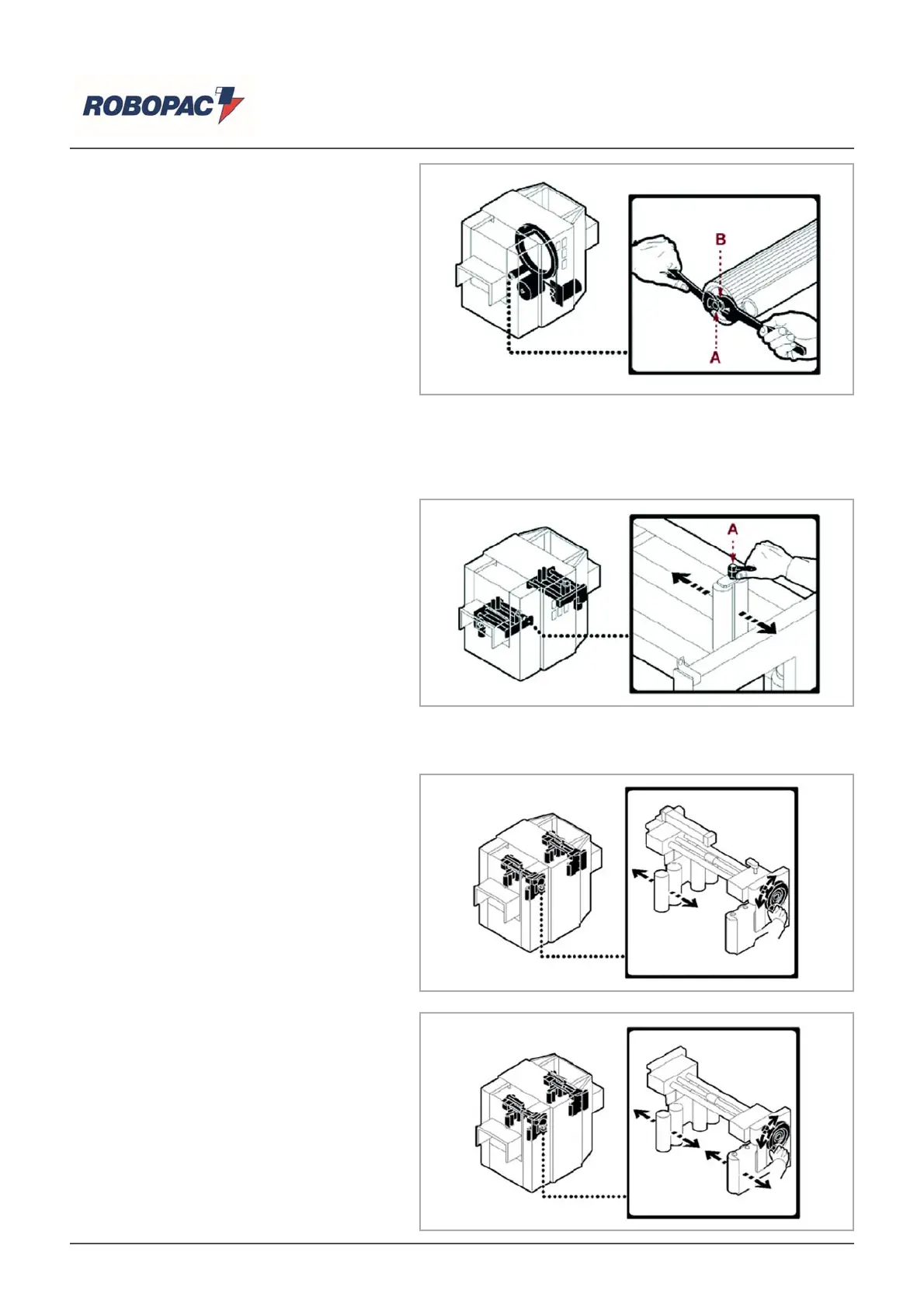

5.3. FILM WRAPPING TENSION

- ADJUSTMENT

1. Loosen nut (A) and rotate flange (B); by

turning clockwise the roller’s braking

effect increases therefore wrapping

tension.

Adjustment is very sensitive, therefore

turn the flange of just a few revolutions

to obtain the desired effect.

2. Once adjustment is performed,

completely tighten the bolt to avoid

loosening during rotation.

Important

Do not exceed with the braking effect.

Avoid an excessive wrapping tension.

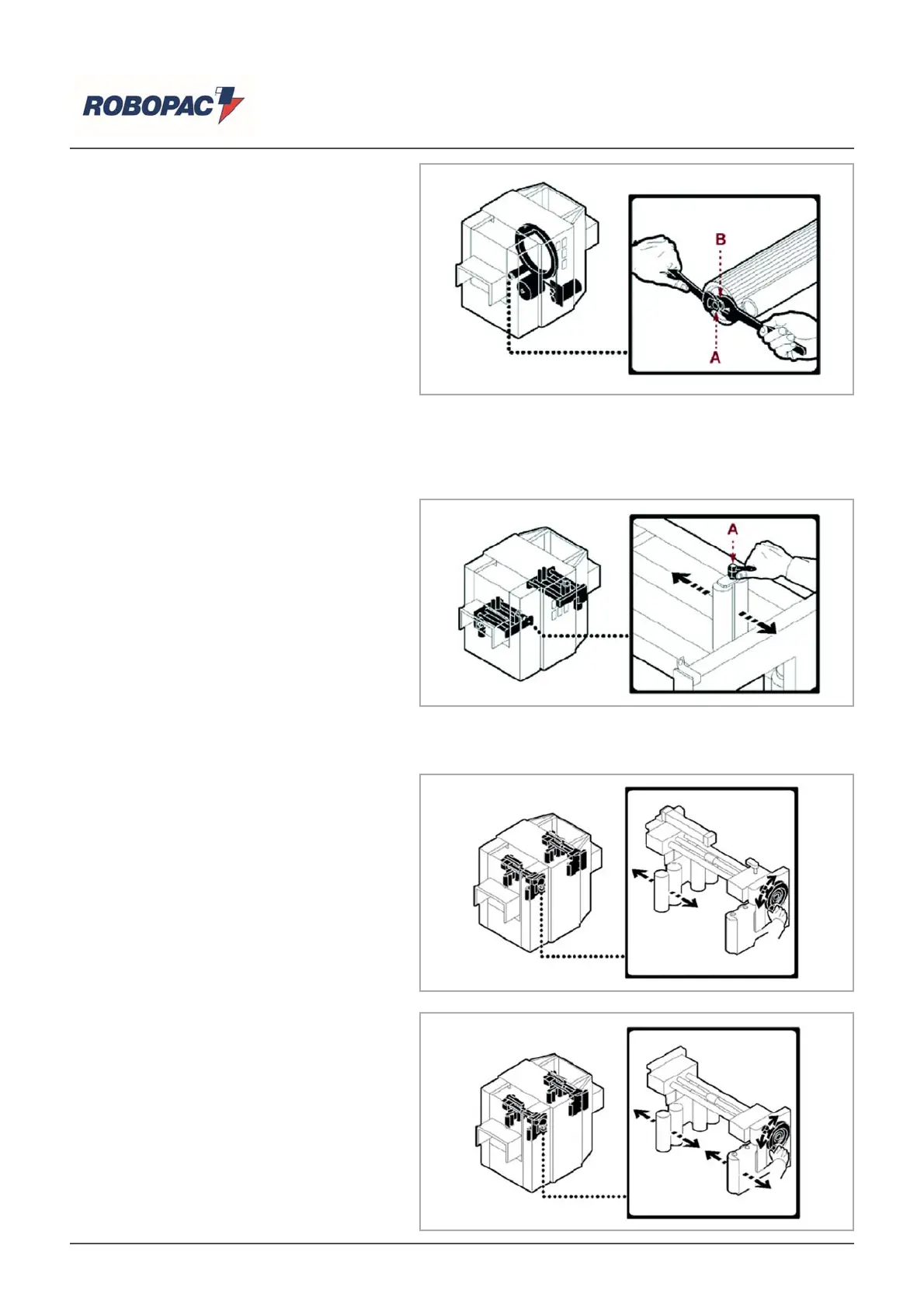

5.4. GUIDE UNITS

ADJUSTMENT

The guide rollers must be adjusted

according to the product length.

1. loosen handle (A) and move the unit.

2. tighten handle.

3. Check that the guide rollers allow the

passage of the product without exerting

any thrust on it.

4. Furthermore, check that the infeed units

are aligned with those on outfeed to

avoid product jamming during

conveyment.

5.4.1.PNEUMATIC GUIDES ON ONE

SIDE

For guides with pneumatic operation on one

side only, adjust the units on the fixed side by

hand wheel.

Adjustment is not necessary for each product

width as the machine works correctly even with

products slightly decentred.

5.4.2.MANUAL SELF-CENTRING

GUIDES

In the self-centring units, adjustment is

performed by hand wheel, allowing positioning

of the guides on both sides.

English

Loading...

Loading...