Publication 2094-UM001A-EN-P — September 2006

Troubleshooting the Kinetix 6000 Drive System 147

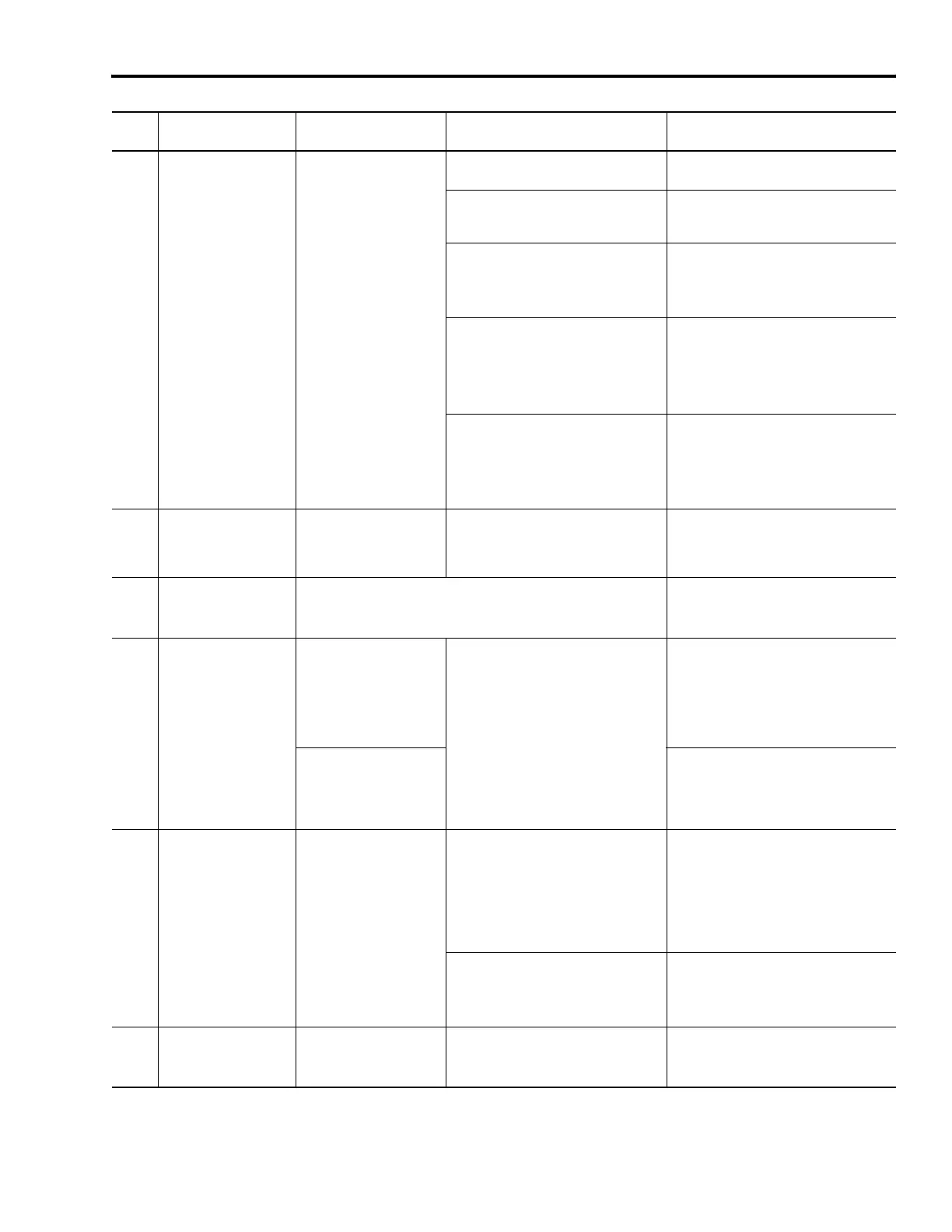

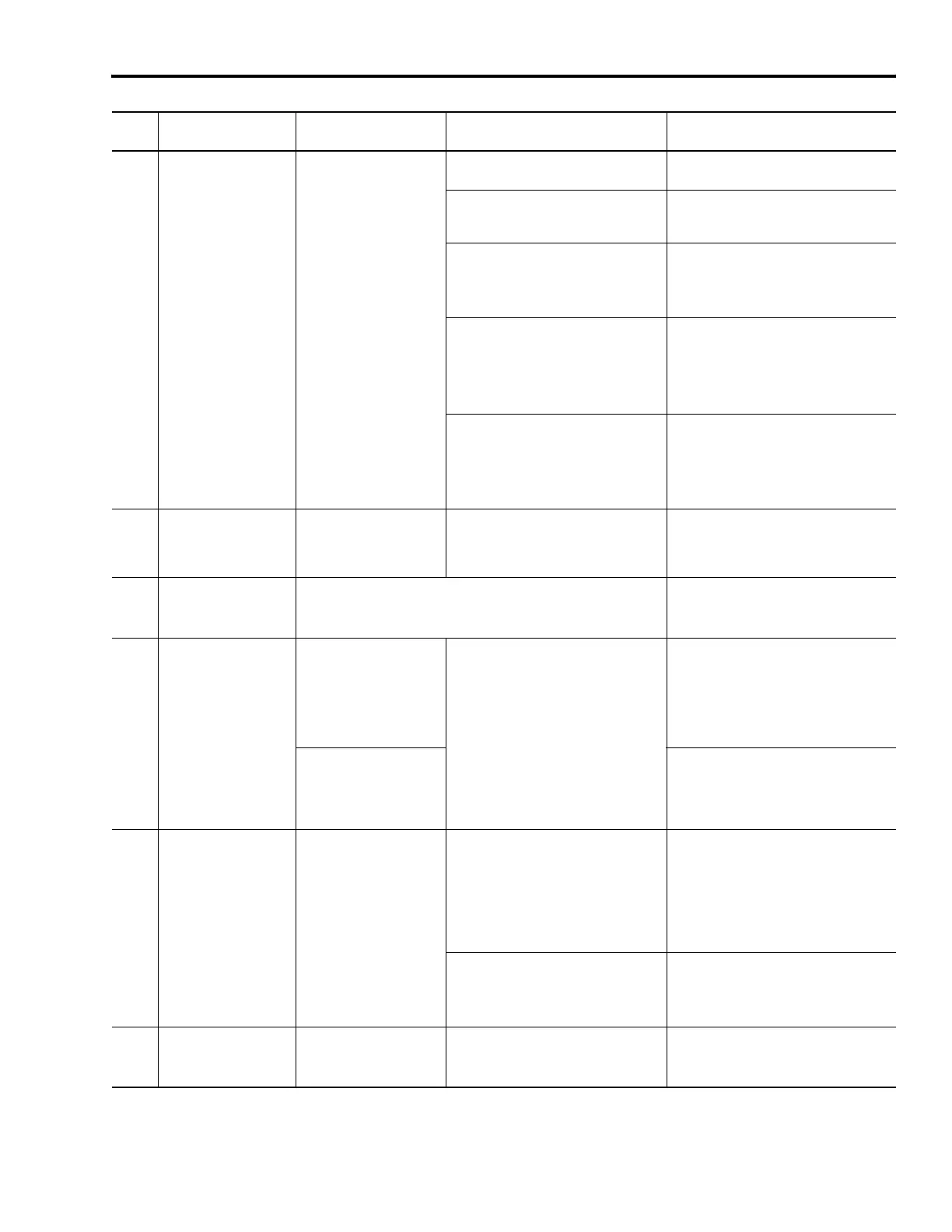

E05

DriveOvercurrent

Fault

(Power Fault)

Self-protection of the

Intelligent Power Module

(IPM) is indicating a major

power related fault

condition.

Motor cables shorted.

Verify continuity of motor power cable and

connector.

Motor winding shorted internally.

Disconnect motor power cables from the

motor. If the motor is difficult to turn by

hand, it may need to be replaced.

Kinetix 6000 temperature too high.

• Check for clogged vents or defective

fan.

• Make sure cooling is not restricted by

insufficient space around the unit.

Operation above continuous power rating

and/or product environmental ratings.

• Verify ambient temperature is not too

high.

• Operate within the continuous power

rating.

• Reduce acceleration rates.

Kinetix 6000 has a short circuit,

overcurrent, or failed component.

Remove all power and motor connections,

and preform a continuity check from the dc

bus to the U, V, and W motor outputs. If a

continuity exists, check for wire fibers

between terminals, or send drive in for

repair.

E06

HardOvertravel

Fault

(+/- Hard Overtravel)

Axis moved beyond the

physical travel limits in the

positive/negative direction.

Dedicated overtravel input is inactive.

• Check wiring.

• Verify motion profile.

• Verify axis configuration in software.

E07

MotFeedbackFault

(Motor Feedback Loss)

The feedback wiring is open, shorted, or missing.

• Check motor encoder wiring.

• Run Hookup test in RSLogix 5000

software.

E09

BusUndervoltage

Fault

(Bus Undervoltage)

With three-phase power

present, the dc bus voltage

is below limits.

• DC bus voltage for 460V system is

below 275V

• DC bus voltage for 230V system is

below 137V

• Verify voltage level of the incoming ac

power.

• Check ac power source for glitches or

line drop.

• Install an uninterruptible power supply

(UPS) on your ac input.

DC bus voltage fell below

the undervoltage limit

while an axis on the

follower power rail was

enabled.

Disable follower axis before removing

power.

E10

DriveOvervoltage

Fault

(Bus Overvoltage)

The dc bus voltage is

above limits.

Excessive regeneration of power.

When the motor is driven by an external

mechanical power source, it may

regenerate too much peak energy

through the drive power supply. The

system faults to save itself from an

overload.

• Change the deceleration or motion

profile.

• Use a larger system (motor and Kinetix

6000 drive).

• Install shunt module.

•

DC bus voltage for 460V system is

over 820V

• DC bus voltage for 230V system is

over 410V

Verify input is within specifications.

E11

MotFeedbackFault

(Illegal Hall State)

State of Hall feedback

inputs is incorrect.

Bad connections.

• Verify the Hall wiring at the MF

connector on the IAM/AM.

• Verify 5V power supply to the encoder.

Error

Code

Fault Message

RSLogix (HIM)

Problem or Symptom Potential Cause Possible Resolution

Loading...

Loading...