Publication 2094-UM001A-EN-P — September 2006

56 Kinetix 6000 Connector Data

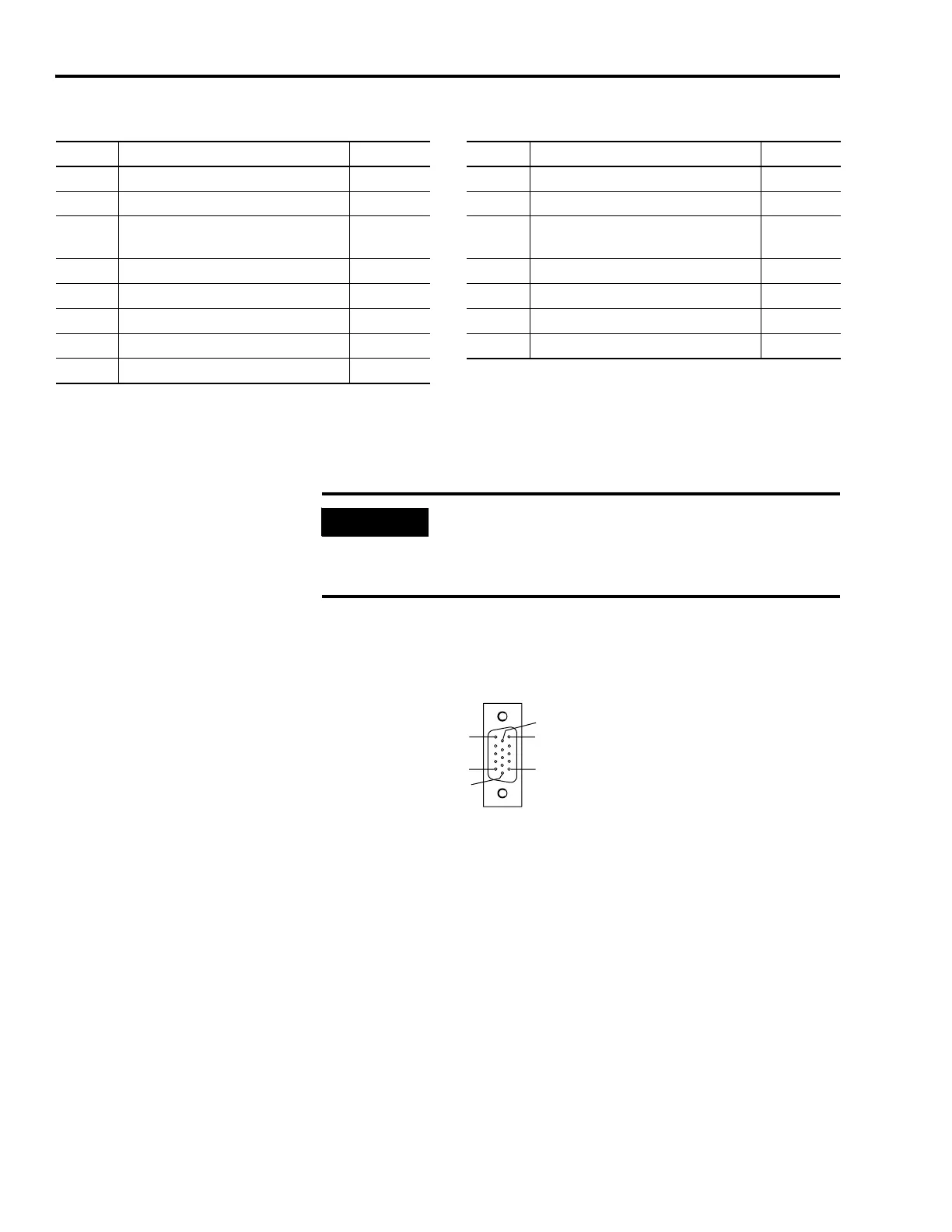

Resolver Transmitter (transformation ratio = 0.25)

Pin Orientation for 15-pin Motor Feedback (MF) Connector

MF Pin Description Signal MF Pin Description Signal

1 Sine differential input+ S2 9 Reserved —

2 Sine differential input- S4 10 Resolver excitation R2

3 Cosine differential input+ S1 11

Motor thermal switch

(normally closed)

(1) (2)

TS

4 Cosine differential input- S3 12 Reserved —

5 Resolver excitation R1 13 Reserved —

6 Common ECOMM 14 Encoder power (+5V) EPWR_5VM

7 Encoder power (+9V) EPWR_9VM 15 Reserved —

8Reserved —

(1)

Not applicable unless motor has integrated thermal protection.

(2)

When using 1326AB (resolver-based) motors, use Low-profile Connector Kit (2090-K6CK-D15MF) that connects the filtered thermal switch (pins 16 and 17) to MF-11 and

MF-6.

IMPORTANT

To meet CE requirements, combined motor power cable length

for all axes on the same dc bus must not exceed 240 m (787 ft)

with 460V systems or 160 m (525 ft) with 230V systems.

Drive-to-motor power cables must not exceed 90 m (295.5 ft).

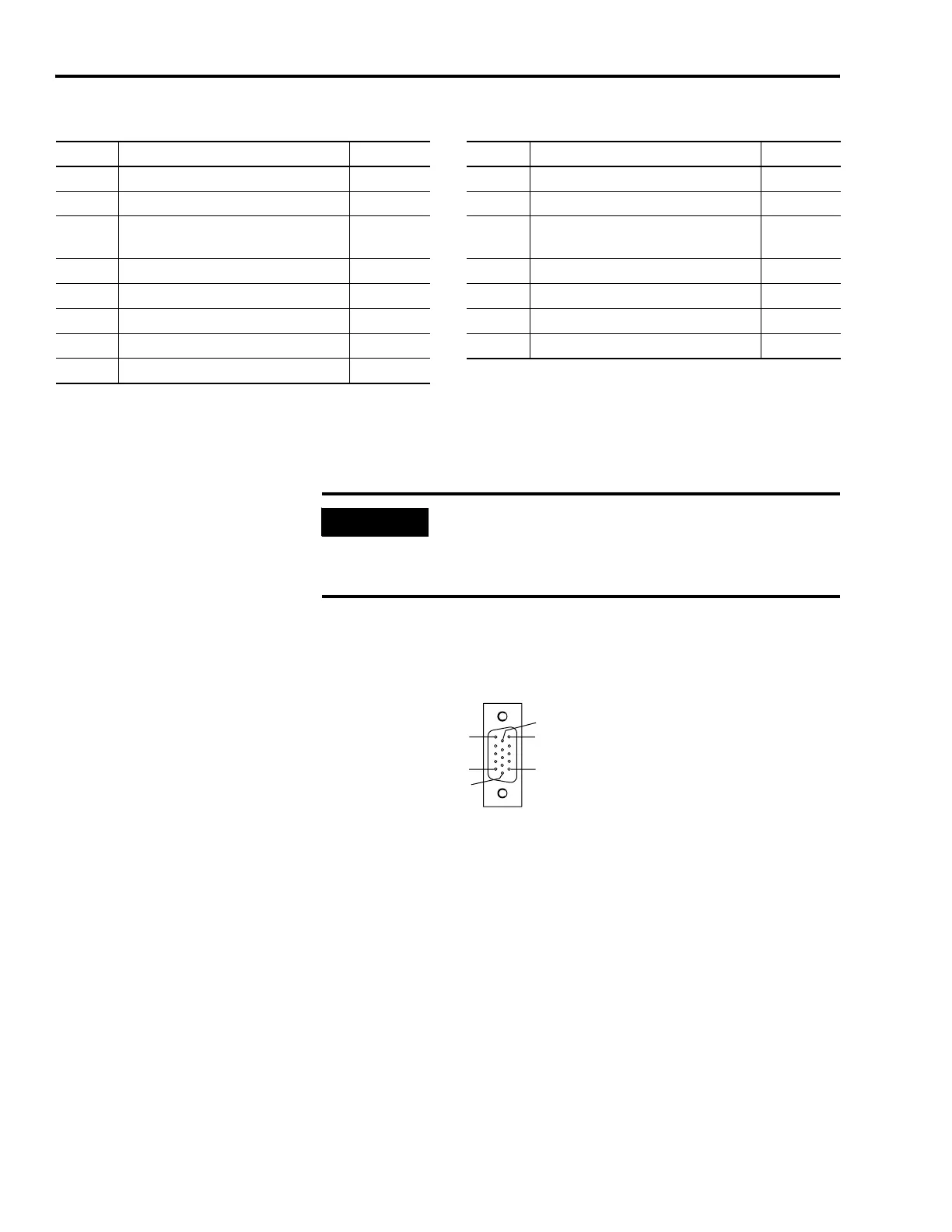

Pin 11

Pin 6

Pin 15

Pin 1

Pin 10

Pin 5

15-pin IAM/AM

Motor Feedback Connector

Loading...

Loading...