d04924.fm

INSTALLATION MANUAL

BRP-Powertrain

Effectivity: 912 Series

Edition 2/Rev. 0

75-00-00

page 25

August 01/2012

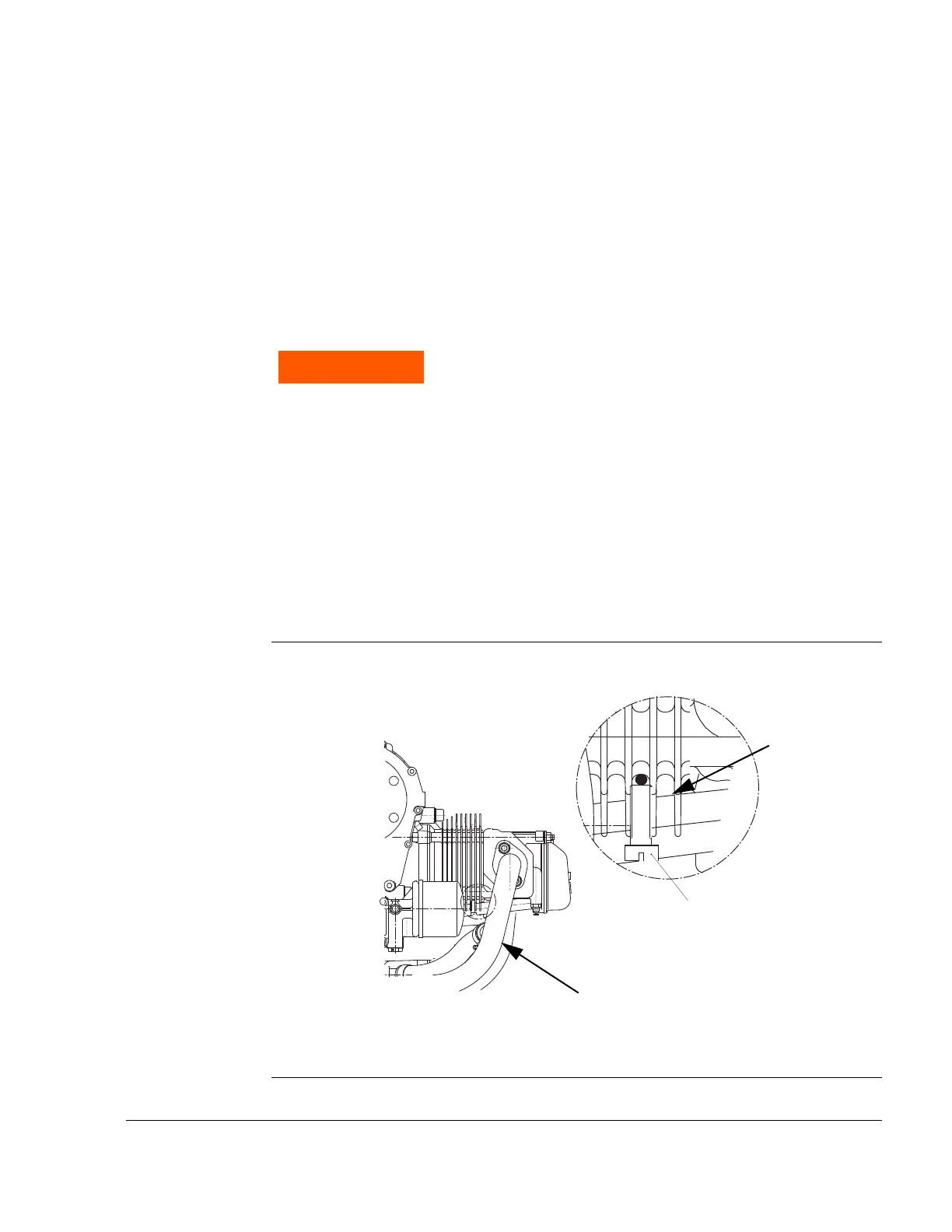

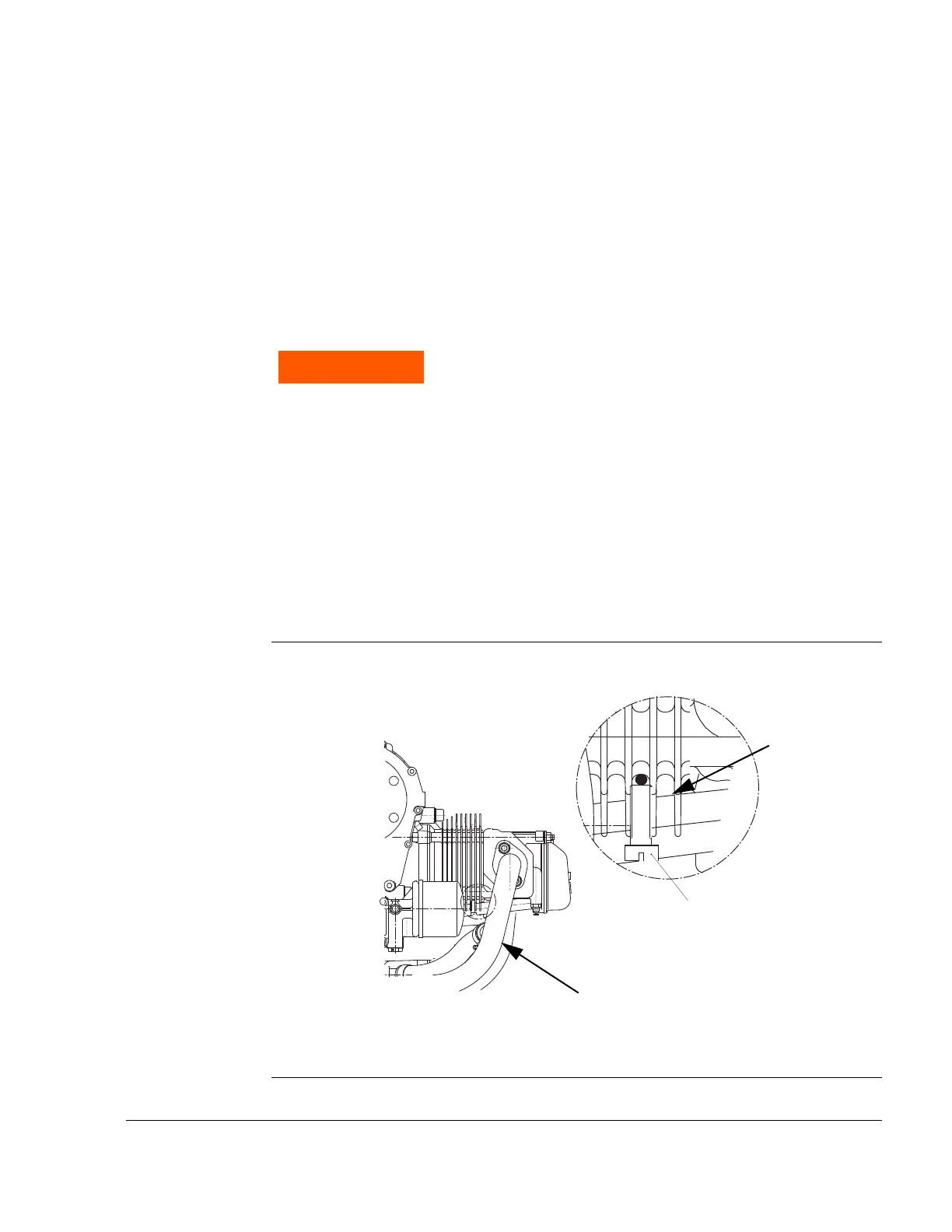

4.2) Cooling air ducts (optional)

General note Cooling air ducts are not required if the oil and coolant temperatures are

within the prescribed operating limits. Otherwise following measurement

must be performed for the first installation of an aircraft type (not in serial-

production).

Hot day condi-

tion

See Fig. 12.

In contrast to the cylinder heads, the cylinders are ram air cooled. Plan the

cooling air ducts according to installation requirement.

Max. permitted cylinder wall temperature on hottest cylinder...200 °C

(392 °F)

NOTE: If this temperature is exceeded, appropriate measures (e.g.

cooling air ducts, modifications to cowling, etc.) must be

taken to bring it within limits again.

NOTE: As long as the oil and coolant temperatures are within the

operating limits, no cooling air ducts are necessary.

Graphic Cooling air duct

Fig. 12

02050

Non-compliance can result in serious injuries or death!

The cooling air ducts must be designed and built such

that the operating temperatures are within the speci-

fied limits and maximum values are not exceeded.

This must also apply to "Hot day condition".

Loading...

Loading...