d04927.fm

INSTALLATION MANUAL

BRP-Powertrain

Effectivity: 912 Series

Edition 2/Rev. 0

79-00-00

page 13

August 01/2012

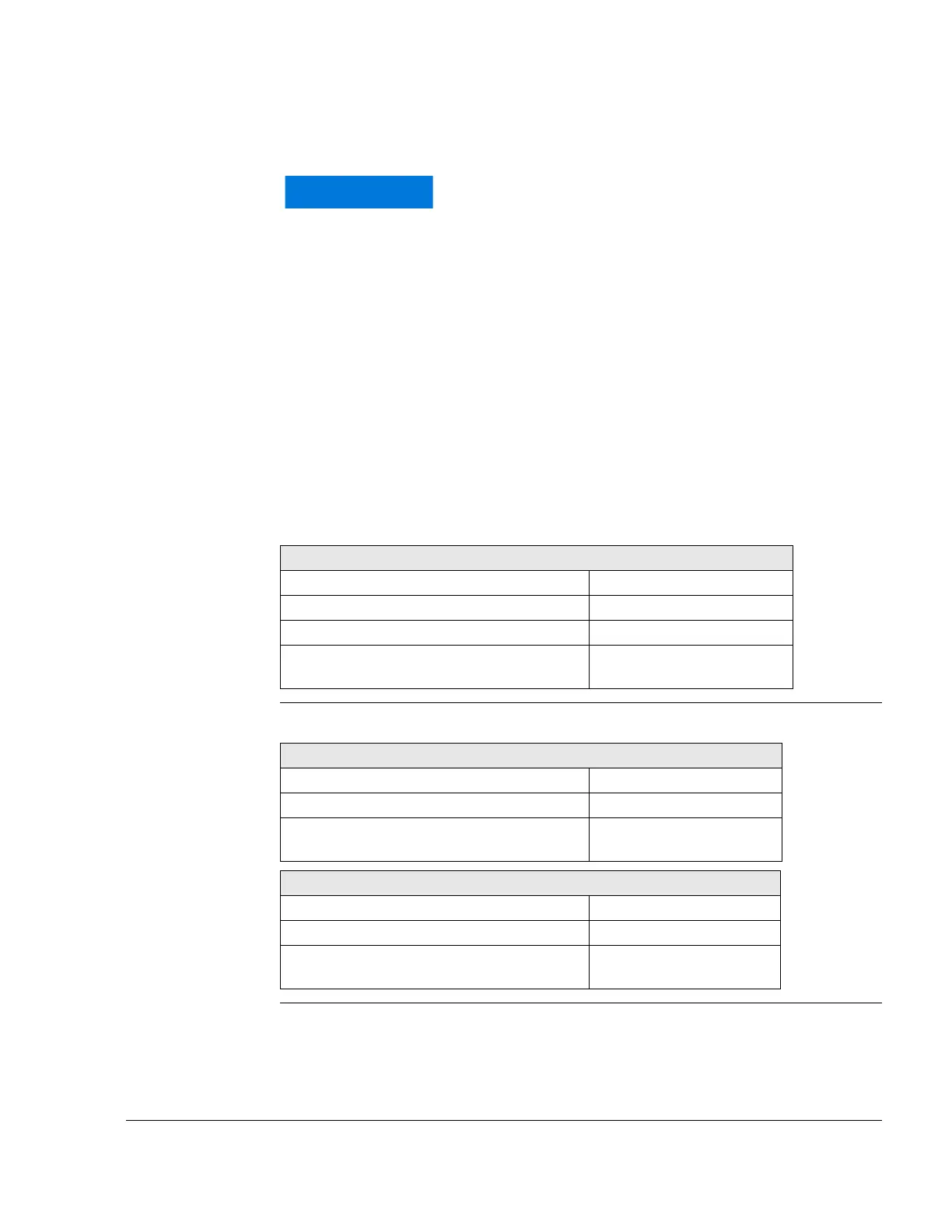

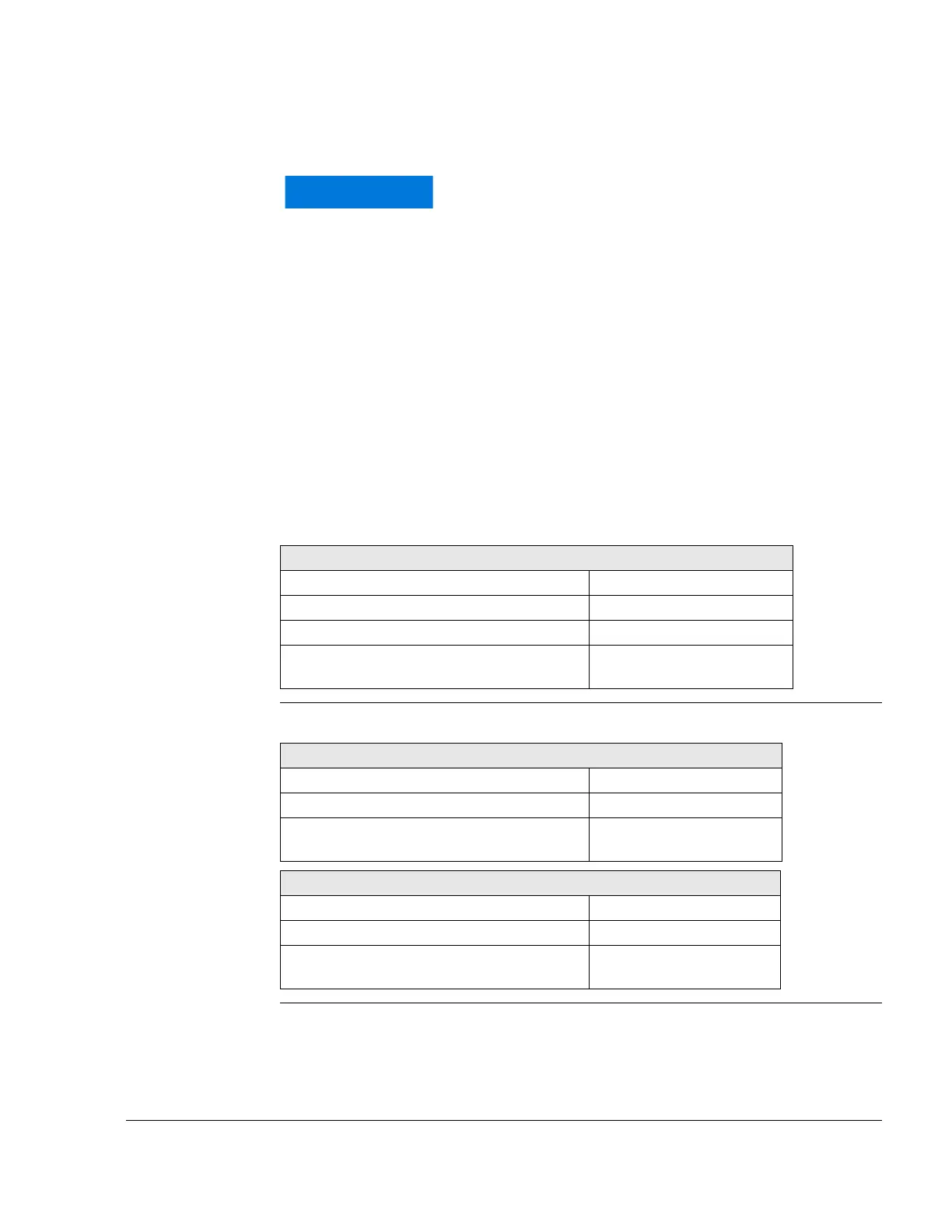

Oil return

See Fig. 8

Select the appropriate connection for the oil return line according to the

propeller configuration and oil system layout.

- Position 1 for tractor or position

- Position 2 for pusher configuration

Connector option Connector option (1), (2) and (5). See Fig. 8.

Option 1: Connection with slip-on connection.

Option 2 and 3 Option 2 and 3: Connection with adaptor (2) or (5).

The engine design is for a conventional, non-aerobat-

ic, tractor or pusher configuration with the oil return

port in the optimum position. Assuming these points

are taken into consideration, the engine will be proper-

ly lubricated in all flight profiles. Aircraft that are not

conventional (e.g. airships, gyrocopters, dive brake

equipped aircraft, etc.) that require engine load at

steep inclination angles may have special lubrication

requirements.

Connection with slip-on connection (1)

Hose nipple (3) 10 DIN 7642

Outside dia. 13.5 mm (.53 in)

Slip-on length Max. 24 mm (max. .94 in)

Tightening torque of banjo bolt (4)

M16x1.5x28.

30 Nm (22 ft.lb)

Connection with adaptor (2)

Thread 3/4-16 UNF (AN-8)

Tightening torque of oil return line. 25 Nm (18.5 ft.lb)

Tightening torque of screw connection (2)

M16x1.5.

25 Nm (18.5 ft.lb)

Connection with screw connection (5)

Thread 3/4-16 UNF (AN-8)

Tightening torquet of oil return line. 25 Nm (18.5 ft.lb)

Tightening torque of banjo bolt (4)

M16x1.5x28.

30 Nm (22 ft.lb)

Loading...

Loading...