7 Troubleshooting

287

S84-ex/S86-ex Operator Manual

7.4.5

Incorrect Print Position

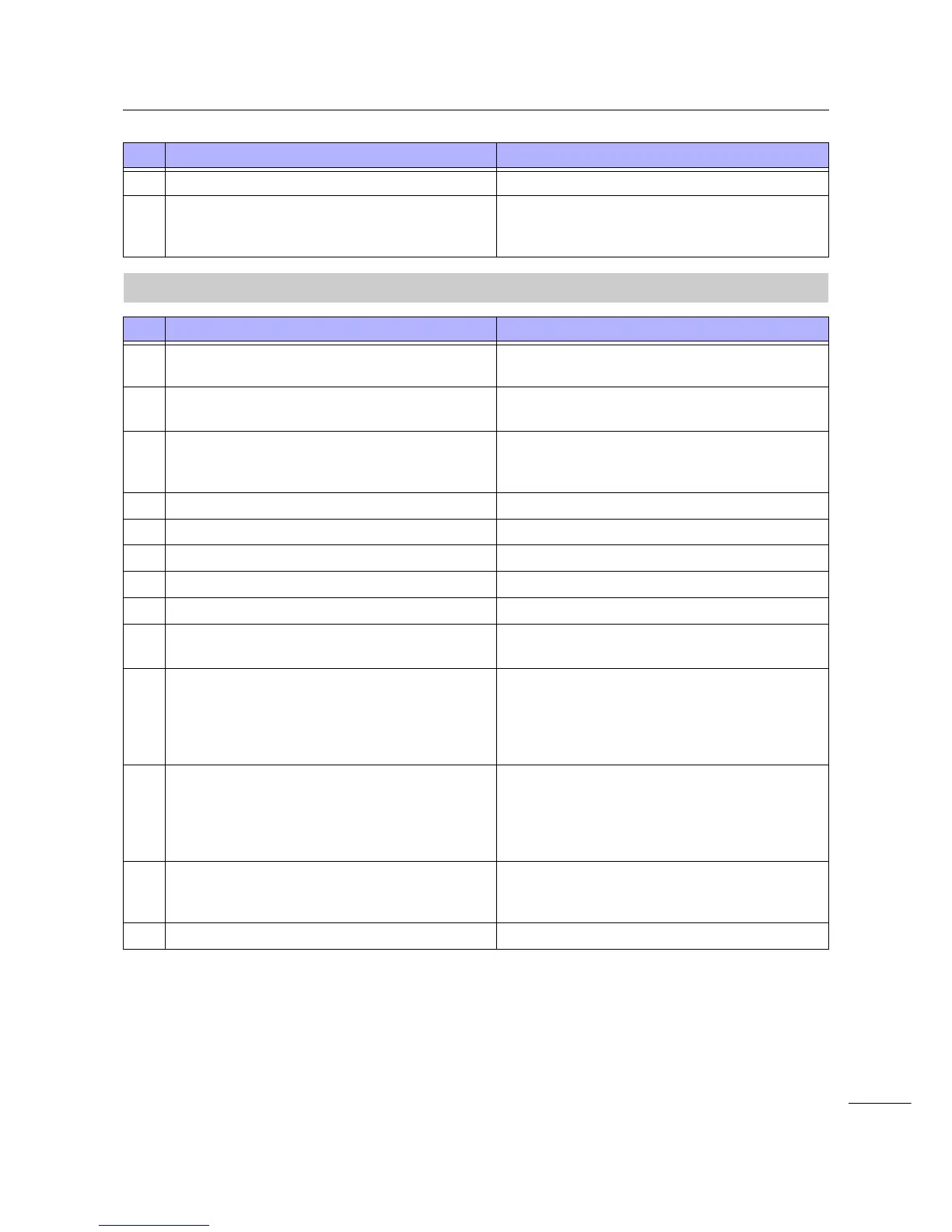

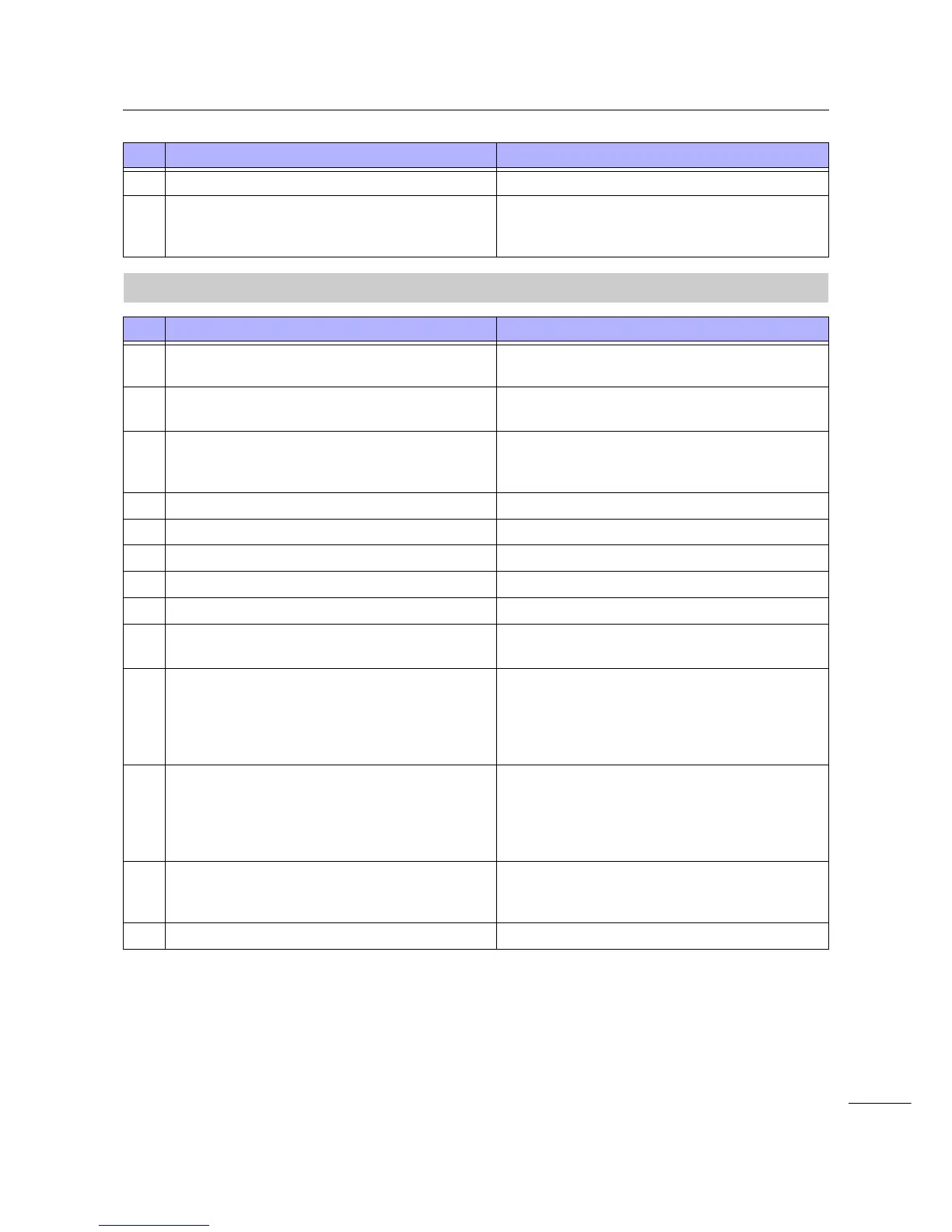

11 Is the platen roller damaged? Replace the platen roller.

12 Is the main (CONT) PCB defective? Replace the main (CONT) PCB.

Contact a SATO reseller or technical service

center for replacement.

No. What to check Countermeasure

1 Are the media and ribbon designed for use with

the printer?

Use media and ribbon designed for the printer.

2 Are the media and ribbon loaded correctly? Check if the media and ribbon are loaded

correctly.

3 Is the media or ribbon deformed? Use the media or ribbon that is not deformed.

You cannot feed the media or ribbon that is

deformed.

4 Is the print head installed correctly? Adjust the print head.

5 Is the media guide set correctly? Adjust the media guide.

6 Is the correct sensor type set? Set the correct sensor type.

7 Is the sensitivity of the sensor set correctly? Adjust the sensor level.

8 Is the offset set correctly? Adjust the offset.

9 Is the pitch offset or base reference point offset

set correctly?

Adjust the pitch offset or base reference point

offset.

10 Is the platen roller dirty? If the platen roller is dirty, clean it using the

cleaning kit.

For printer cleaning, refer to Section 6.2

Maintenance of the Print Head and Platen

Roller.

11 Is the media sensor dirty? If the media sensor is dirty, clean it using the

cleaning kit.

For printer cleaning, refer to Section 6.2

Maintenance of the Print Head and Platen

Roller.

12 Is the data or signal sent from the computer

incorrect?

Power on the device again.

Check the data sent from the computer and

communication conditions.

13 Is the platen roller damaged? Replace the platen roller.

No. What to check Countermeasure

Loading...

Loading...