90

©

Scania CV AB 2011, Sweden

01:03-02

6 Insert the connecting rod bearing shell in the

connecting rod cap, lubricate the bearing

surface and fit the connecting rod cap.

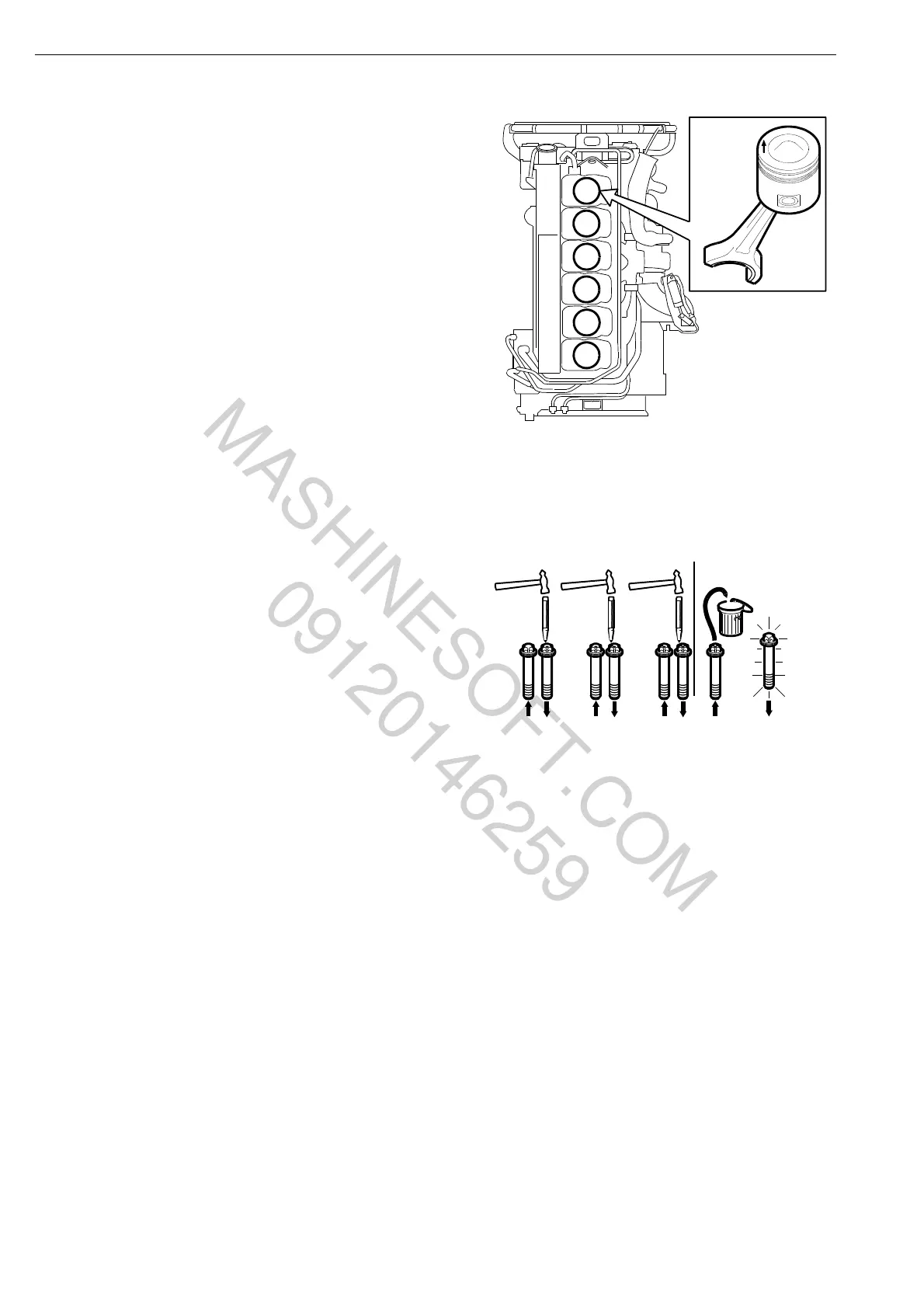

7 Fit the connecting rod and piston. The arrow

on the piston must be facing the front of the

engine. Applies only to aluminium pistons;

steel pistons are symmetrical. Clamp the

piston ring compressor 98 212 and push the

piston into the cylinder.

The arrow must be facing forwards in the

direction of the engine.

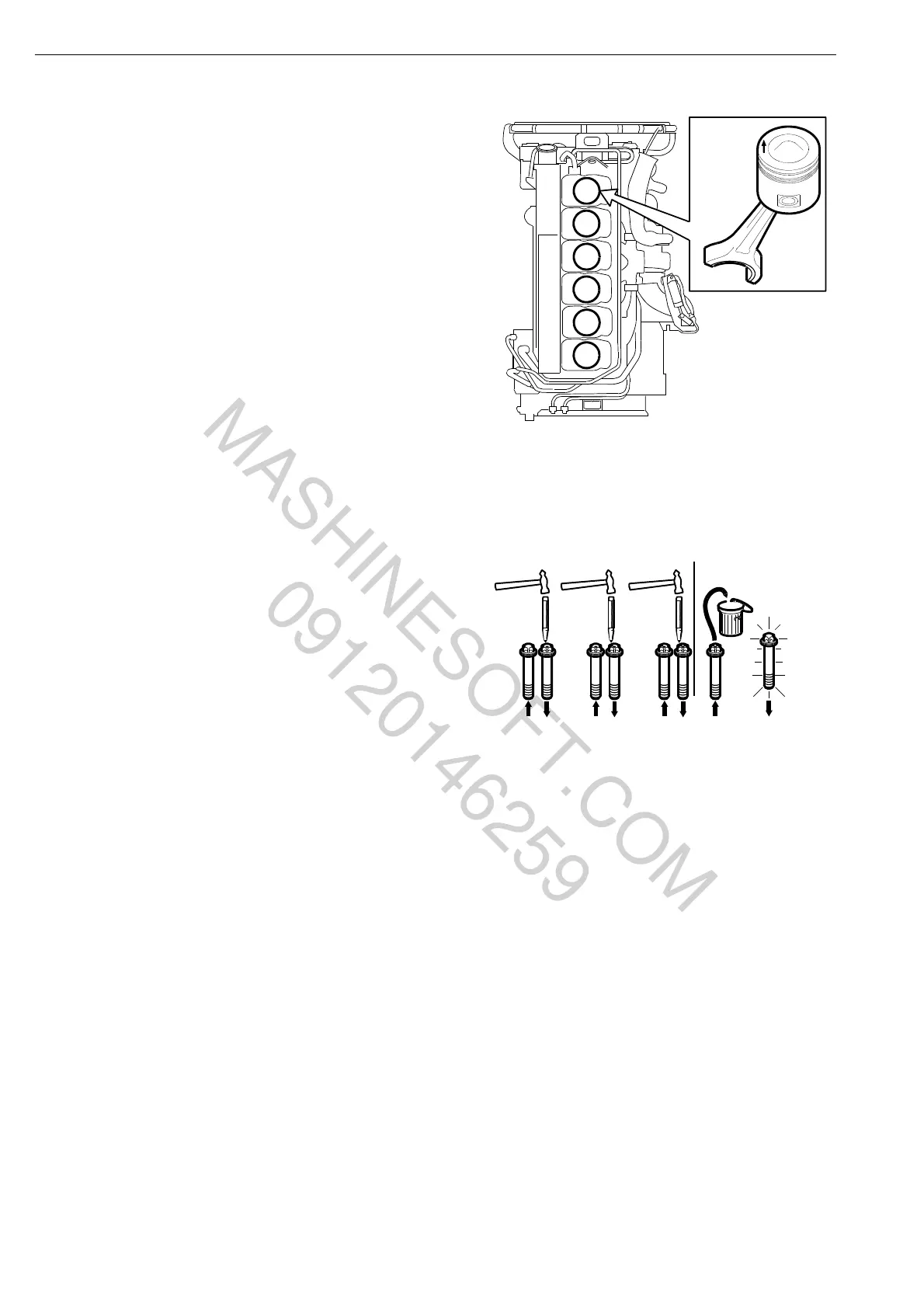

8 For connecting rod cap with four bolts:

Lubricate the bolts, fit them and torque

tighten to 20 Nm + 90°. The bolts may only

be reused a maximum of 3 times. Mark the

bolt with a punch mark each time you reuse

it; see figure. If a bolt already has three

marks, it must be renewed.

For connecting rod cap with two bolts:

The bolts must not be reused. Always

replace the bolts with new ones. Lubricate

the bolts, fit them and torque tighten to

50 Nm + 90°.

9 Fit the piston cooling nozzle. Tightening

torque 23 Nm.

IMPORTANT! The piston cooling nozzle must

not be damaged. The oil jet must hit the piston

precisely. If it does not, the piston will become

too warm, resulting in engine breakdown.

Damaged nozzles must not be re-aligned; renew

them instead.

10 Fit the oil sump.

11 Fit the cylinder head. Tighten the cylinder

head bolts according to the section Fitting

the cylinder head.

Crank mechanism

MASHINESOFT.COM

09120146259

Loading...

Loading...