10

Project planning

MOVIMOT® advanced

Operating Instructions – MOVIMOT

®

advanced

230

Run-in phase

The tooth flanks of new helical-worm and SPIROPLAN

®

gear units are not yet com-

pletely smooth. This makes for a greater friction angle and less efficiency during the

run-in phase than during later operation. This effect intensifies with increasing gear

unit ratio.

During the running-in phase, the nominal efficiency of the gear unit is reduced by the

respective value in the following tables.

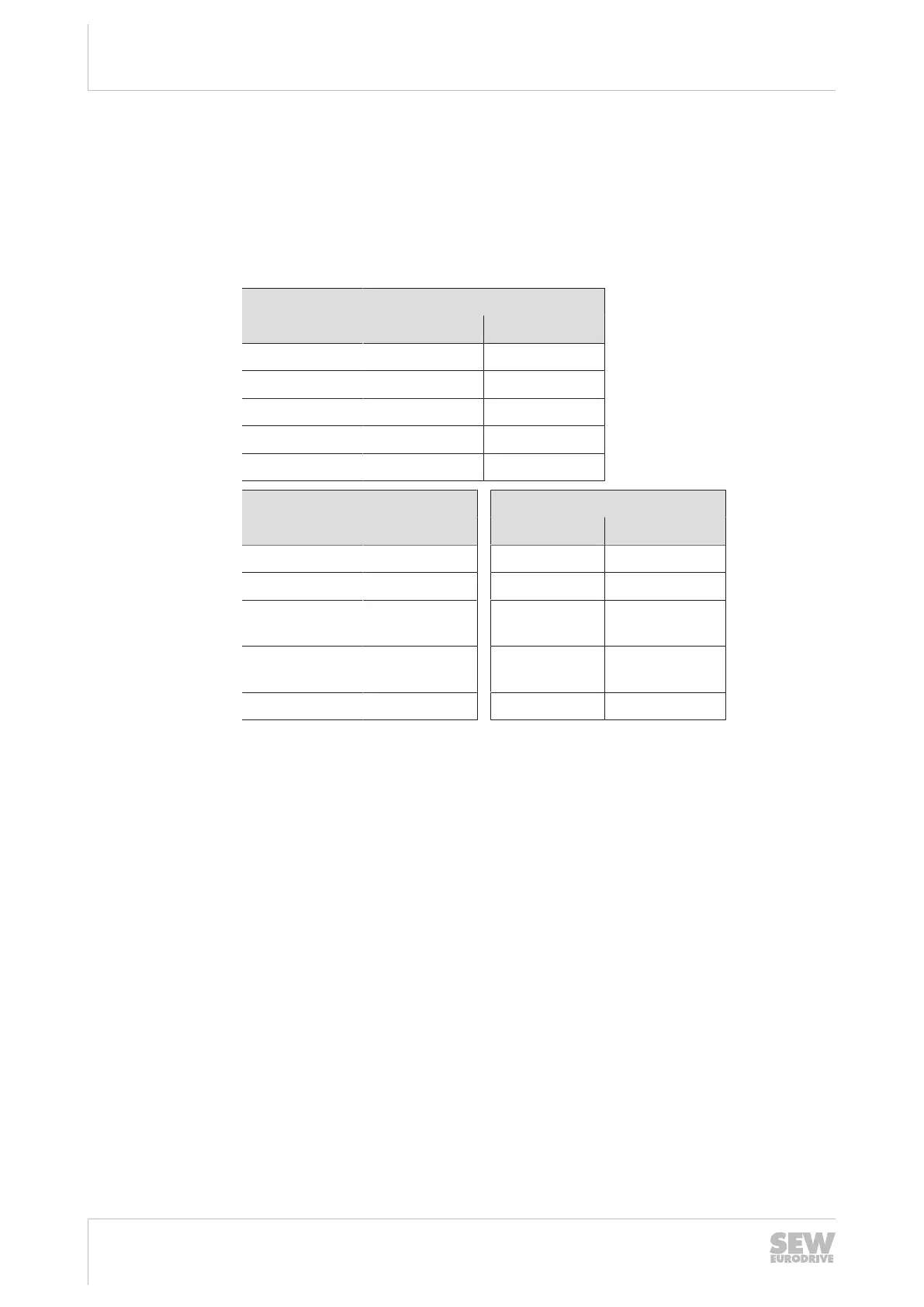

Worm

i range η reduction

1-start About 50–280 Approx. 12%

2-start approx. 20–75 approx. 6%

3-start approx. 20–90 approx. 3%

5-start approx. 6–25 approx. 3%

6-start approx. 7–25 approx. 2%

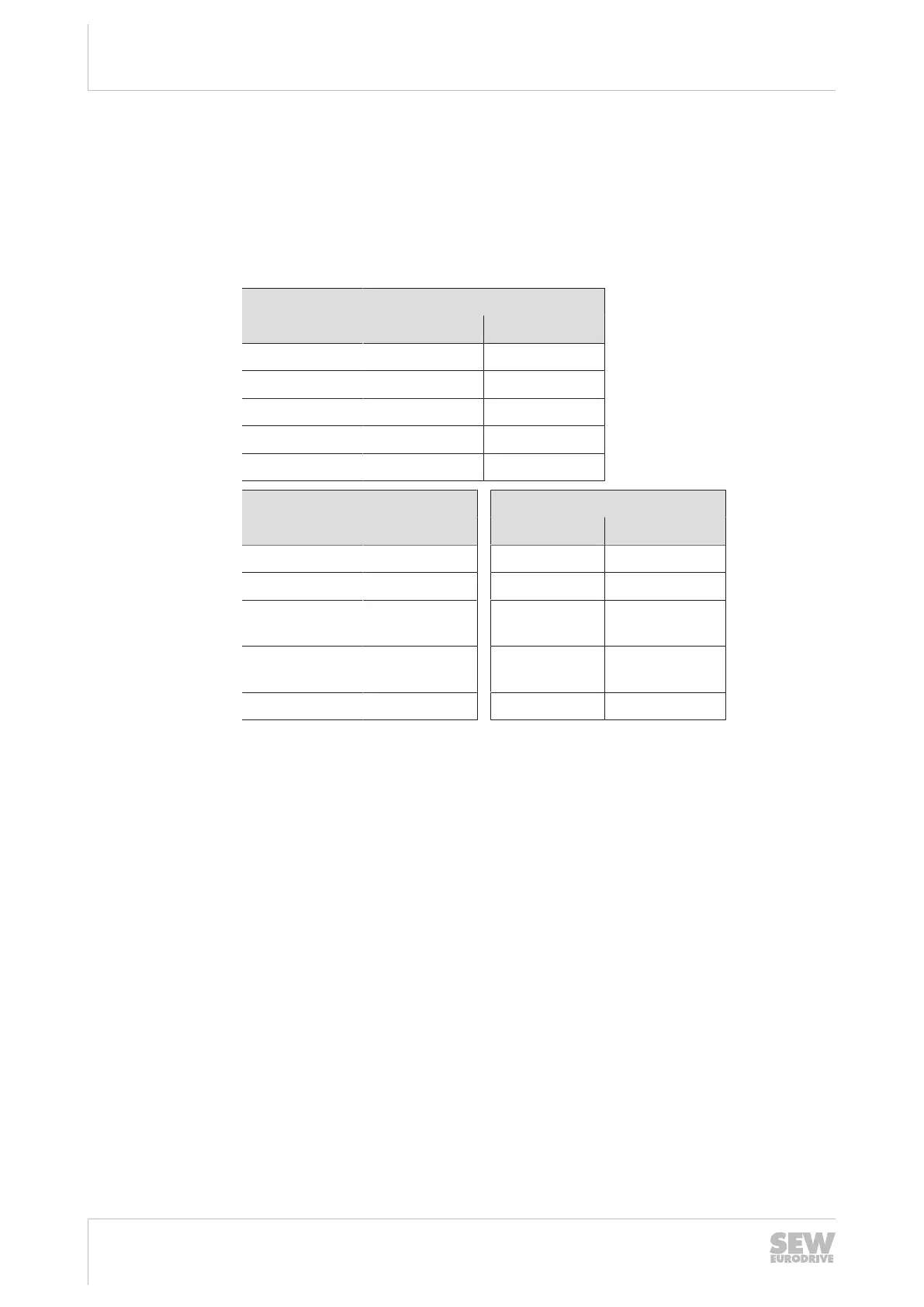

SPIROPLAN

®

W10 to W30 SPIROPLAN

®

W37 to W47

i range η reduction i range η reduction

approx. 35–75 approx. 15% – –

approx. 20–35 approx. 10% – –

approx. 10–20 approx. 8% approx. 30–

70

approx. 8%

approx. 8 approx. 5% approx. 10–

30

approx. 5%

approx. 6 approx. 3% approx. 3–10 approx. 3%

The run-in phase usually lasts 48 hours. Helical-worm and SPIROPLAN

®

gear units

achieve their nominal efficiency values when the following conditions have been met:

• The gear unit has been completely run-in.

• The gear unit has reached nominal operating temperature.

• The recommended lubricant has been filled.

• The gear unit is operating in the nominal load range.

Operation at motor speeds above 1800min

-1

SEW-EURODRIVE recommends using oil seals on the A- and B-side made of fluoro-

carbon rubber for motors and gearmotors operated on frequency inverters at motor

speeds above 1800min

-1

.

25891936/EN – 05/2020

Loading...

Loading...