4

Mechanical installation

Installation requirements

Operating Instructions – MOVIMOT

®

advanced

28

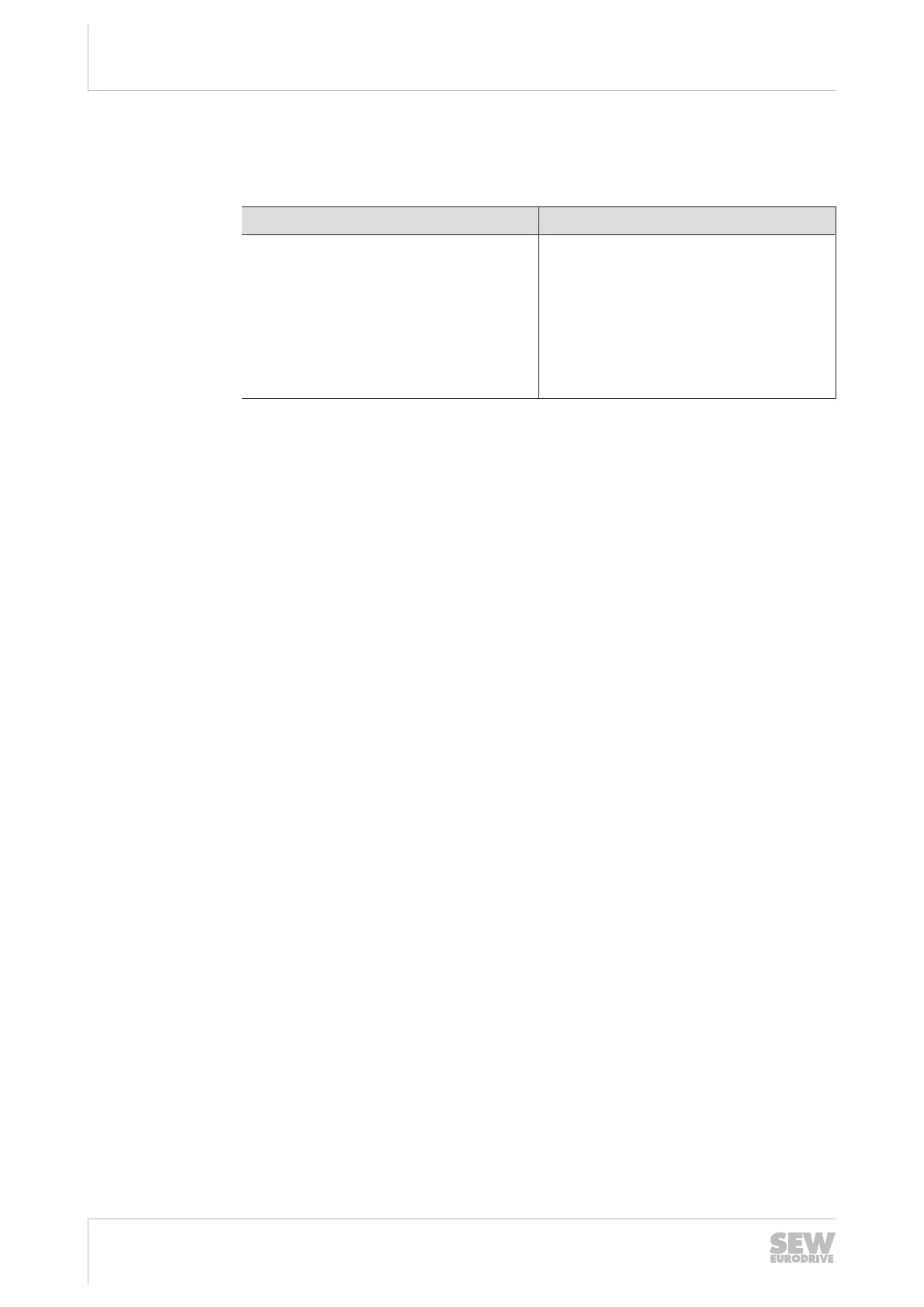

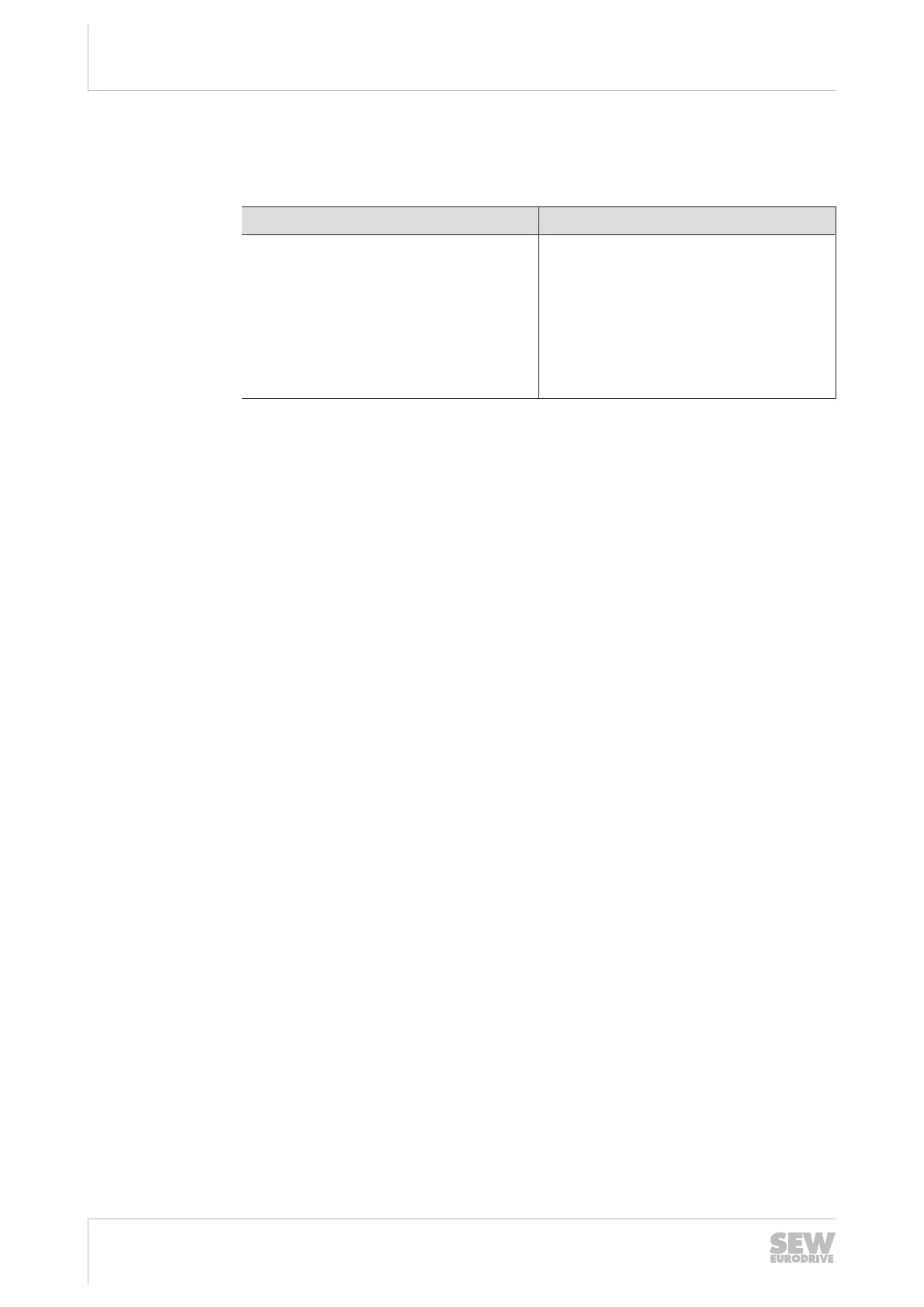

4.2.1 Installation tolerances for motor shaft ends

The following table shows the permitted tolerances of the shaft ends and flanges of

the drive unit.

Shaft end Flanges

Diameter tolerance according to

EN50347

• ISO j6 at Ø ≤28mm

• ISO k6 at Ø ≥ 38mm≤ 48mm

• ISO m6 at Ø ≥ 55 mm

• Center hole according to DIN332,

shape DR..

Centering shoulder tolerance according

to EN50347

• ISO j6 at Ø ≤ 250mm

• ISO h6 with Ø ≥ 300 mm

4.2.2 Tolerances for torque ratings

The specified torques must be adhered to with a tolerance of +/-10%.

4.3 Installation requirements

Check that the following conditions have been met:

• The information on the drive unit's nameplate must match the voltage supply sys-

tem.

• The drive unit is undamaged (no damage caused by shipping or storage).

• Ambient temperature according to the operating instructions, nameplate and lubri-

cant table in the gearmotor catalog "DRN63 – 315, DR2S56 – 80, DR2L71 – 80".

• The drive unit must not be installed in the following ambient conditions:

– Potentially explosive atmosphere

– Oils

– Acids

– Gases

– Vapors

– Radiation

• For special designs: The drive unit is designed in accordance with the actual ambi-

ent conditions.

• Clean the output shafts and flange surfaces thoroughly to ensure that they are free

of anti-corrosion agents, contamination or similar. Use a commercially available

solvent. Do not expose the sealing lips of the oil seals to the solvent – damage to

the material.

• When the drive is installed in abrasive ambient conditions, protect the output end

oil seals against wear.

25891936/EN – 05/2020

Loading...

Loading...