128

Operating Instructions – Electronic Motor DRC.-..-SNI

8

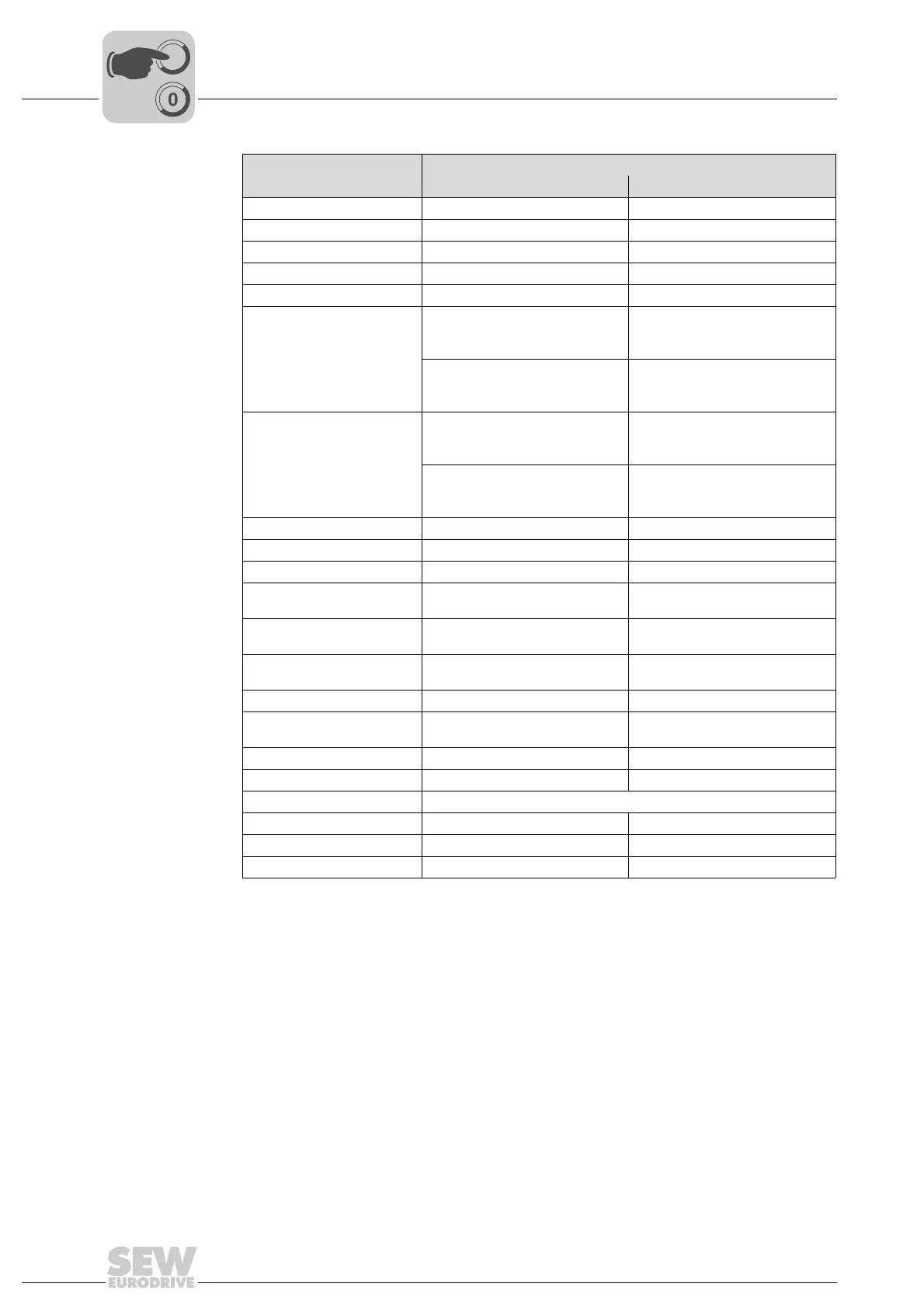

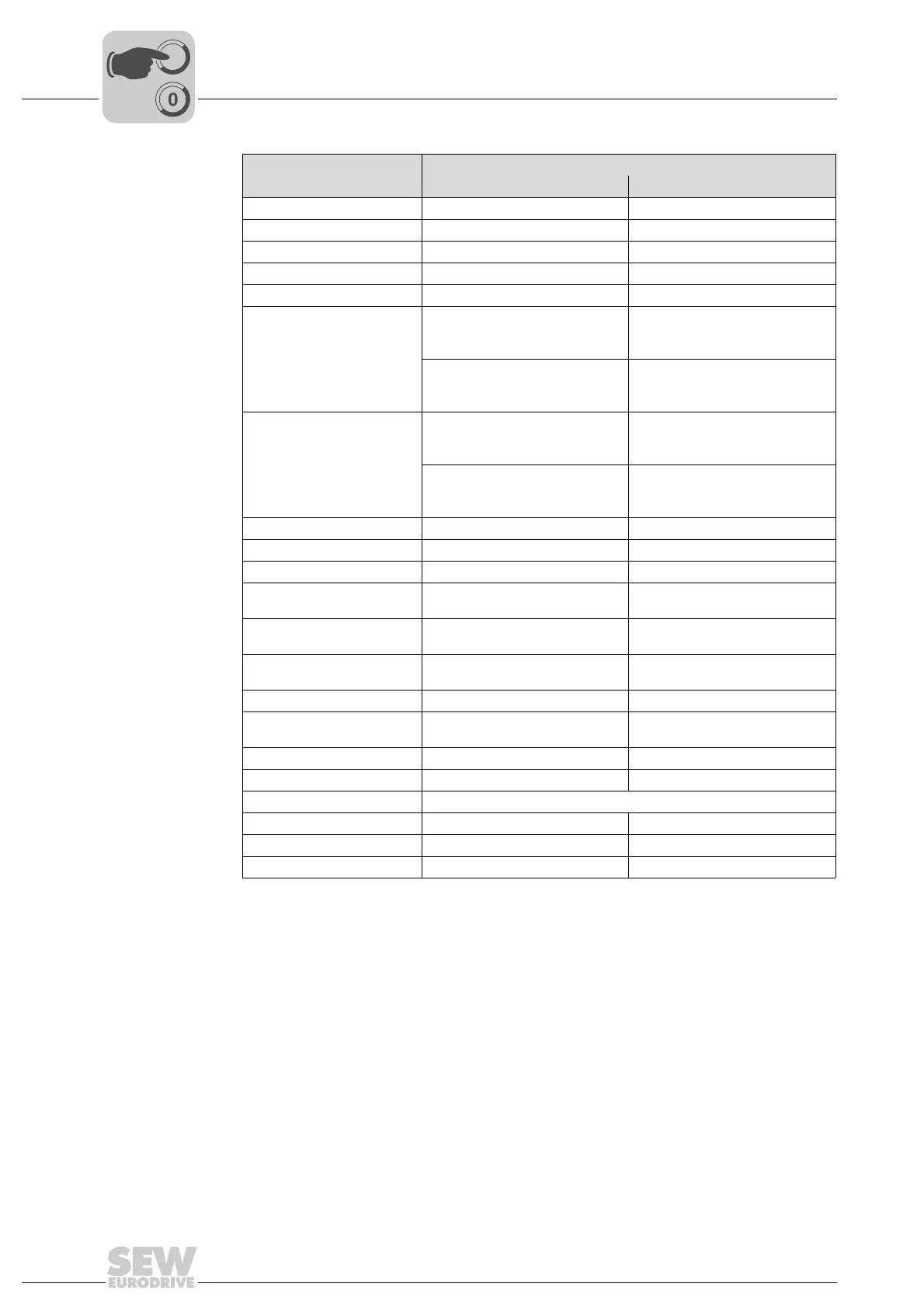

Description of power section parameters

Parameters

Function

Binary output has

"0" signal "1" signal

0 = No function Always "0" signal –

1 = /Fault Collective fault signal –

2 = Ready Not ready Ready for operation

3 = Output stage ON Unit inhibited Unit enabled and motor energized

4 = Rotating field ON No rotating field Rotating field

5 = Brake released

1)

In conjunction with mechatronic

MOVIGEAR

®

drive unit:

DynaStop

®

is activated

In conjunction with mechatronic

MOVIGEAR

®

drive unit:

DynaStop

®

is deactivated

In conjunction with DRC

electronic motor:

Brake applied

In conjunction with DRC

electronic motor:

Brake released

6 = Brake applied

1)

In conjunction with mechatronic

MOVIGEAR

®

drive unit:

DynaStop

®

is deactivated

In conjunction with mechatronic

MOVIGEAR

®

drive unit:

DynaStop

®

is activated

In conjunction with DRC

electronic motor:

Brake released

In conjunction with DRC

electronic motor:

Brake applied

7 = Motor standstill Motor is running Motor is at standstill

8 = Reserved ––

9 = Speed reference signal n > n

ref

(n < n

ref

)n < n

ref

(n > n

ref

)

10 = Speed reference signal

Speed is outside (within) speed

window

Speed is within (outside) speed

window

11 = Setpoint/actual value

comparison signal

n <> n

set

(n = n

set

)n = n

set

(n <> n

set

)

12 = Current reference

signal

I > I

ref

(I < I

ref

)I < I

ref

(I > I

ref

)

13 = Imax signal I < I

max

(I = I

max

)I = I

max

(I < I

max

)

14 = /Warning motor

utilization

100% pre-warning of motor

protection function

–

19 = IPOS in position Position not reached Position reached

20 = IPOS referenced No referencing Referencing finished

21 = IPOS output Depends on IPOS program

22 = /IPOS fault IPOS program error message –

27 = STO – safe torque off Not active Active

34 = Process data bit Bit not set Bit set

1) Controlled by the inverter The "Brake released" and "Brake applied" signals are intended to be passed on

to a master controller.

Loading...

Loading...