48

8012707/ZVF9/V2-1/2019-04 | SICKOPERATING INSTRUCTIONS | GM32

Subject to change without notice

6 MAINTENANCE

6 Maintenance

6.1 Maintenance plan (operator)

6.1.1 Recommended expendable and wearing parts for 2 years operation

6.2 Preparation work

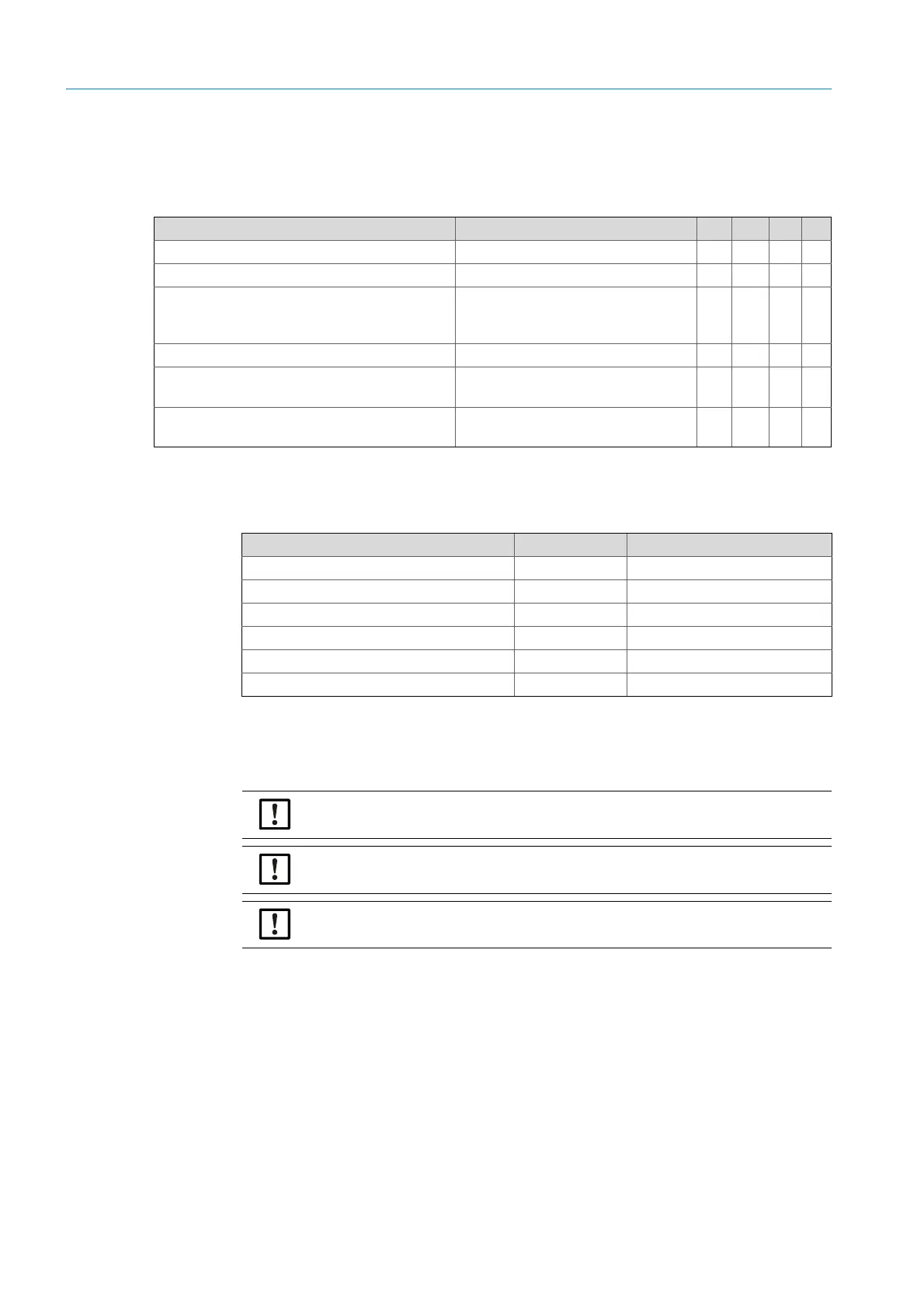

Maintenance task Reference w

[1]

[1] w = weekly, q = quarterly, h = every half year, y = yearly

q

[1]

h

[1]

y

[1]

Visual inspection see “Visual inspection”, page 49 xxx

Cleaning the window see “Cleaning the window”, page 50 xxx

Checking the desiccant cartridges, replace when

necessary.

Replace at the latest after 6 months.

see “Checking and replacing the desic-

cant cartridges”, page 50

xxx

Renewing the activated charcoal sachet SICK Service x

Checking the purge air unit (for GMP probe)

see “Cleaning the purge air unit”, page

53

xxx

Checking optical alignment

see “Alignment check (automatic opti-

cal alignment check; option)”, page 45

xxx

Table 11: Maintenance plan

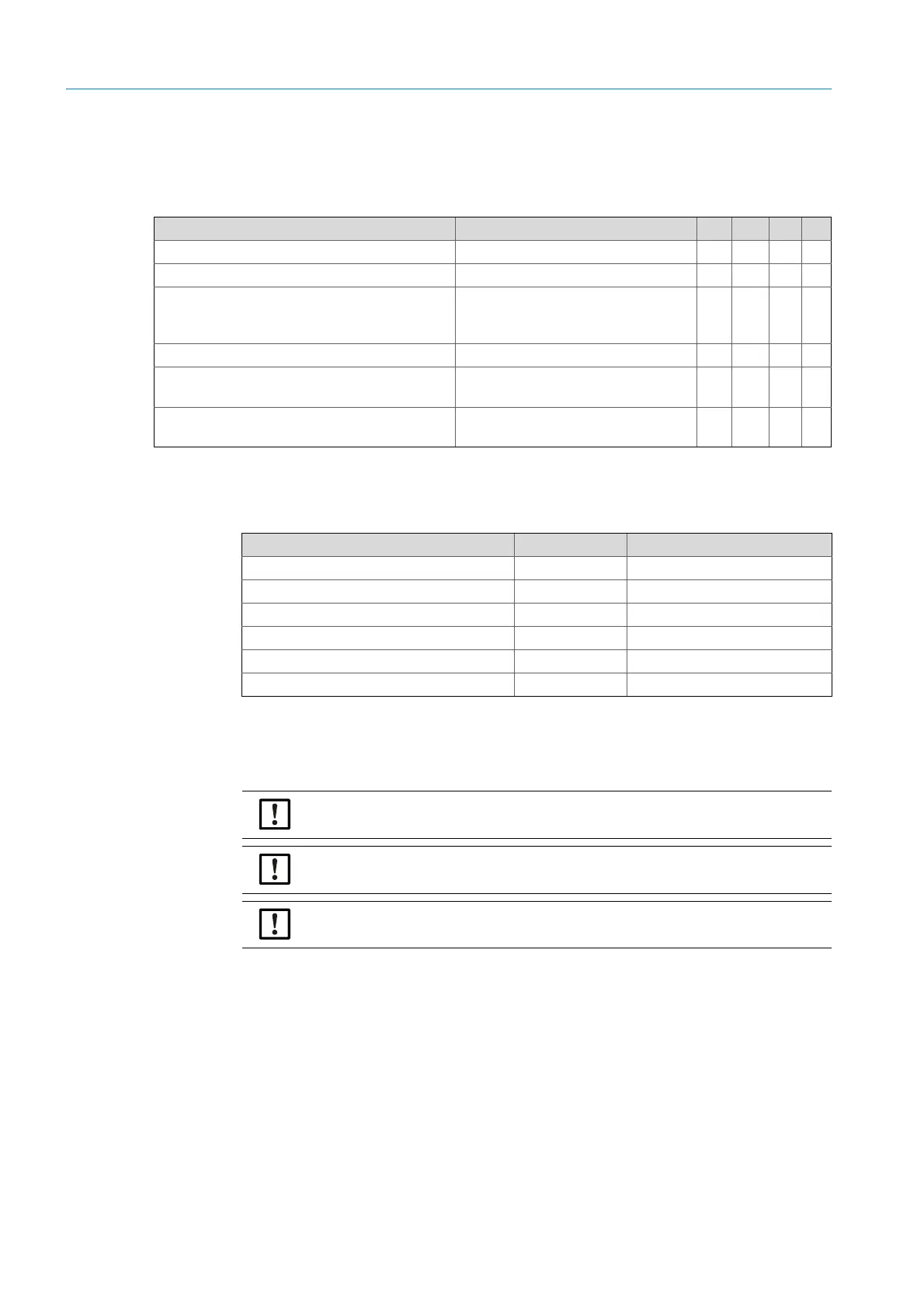

Spare part Number Part number

[1]

[1] Per piece

Sender lamp 2 pcs 2082776

Sender lamp GM32 LowNOx 2 pcs 2086187

Desiccant cartridge 8 pcs 2010549

Activated charcoal bag 2 pcs 5323946

Optical cleaning cloth 8 pcs 4003353

Filter insert for purge air unit 8 pcs 5306091

Table 12: Expendable and wearing parts

NOTE: Some tasks cause the GM32 to switch to malfunction

▸ Activate Maintenance mode before starting work, see page 47.

NOTE: Do not switch the purge air off

!▸

Do not switch the purge air unit off as long as the SR-unit is still on the gas duct.

NOTE: With the GPP probe: Danger of condensation

!▸

Do not switch off the heater of the GPP probe as long as the probe is in the gas duct.

Loading...

Loading...