56

8012707/ZVF9/V2-1/2019-04 | SICKOPERATING INSTRUCTIONS | GM32

Subject to change without notice

7 CLEARING MALFUNCTIONS

7.2.4 Corrosion on probe or flanges

7.2.5 Measured value blinks

If a measured value blinks: Measured value is “uncertain” (e.g. calibration range

exceeded).

For GMP probe: When all measured values blink: Is the lever for the diaphragm in the

“open” position (see “Installing the SR-unit on the device flange”, page 36)?

7.3 Error messages

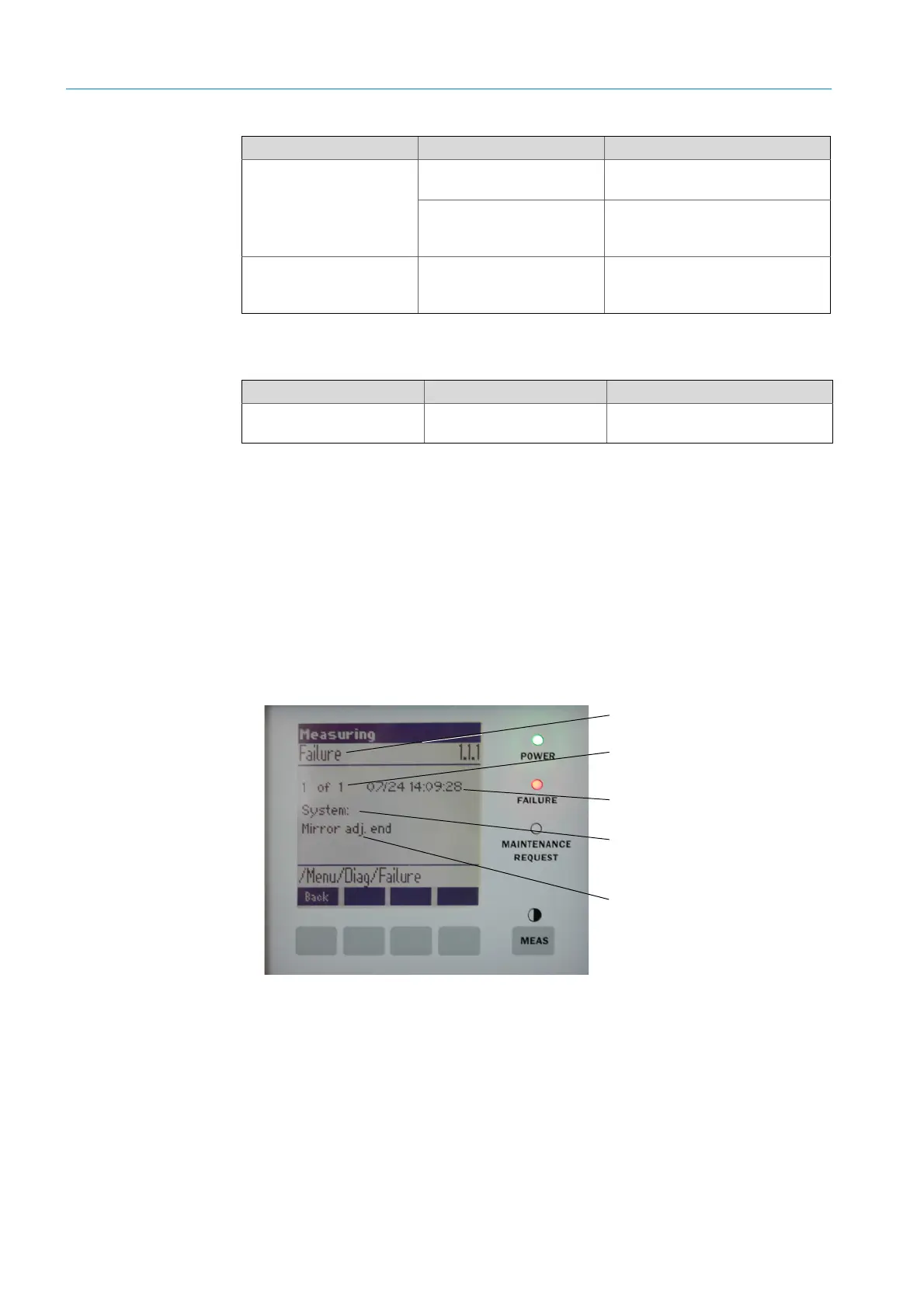

7.3.1 Example of an error message

Fig. 38: Example of an error message

Error Possible causes Remedy

Sample gas penetrating the

area before the SR-unit.

● Gas pressure in gas duct

too high.

▸ Check project planning.

● Purge air unit has failed or

is too weak.

▸ Check purge air unit.

▸ Plan redundant purge air unit.

▸ Strengthen purge air unit.

Sample gas penetrating the

GMP probe.

● Purge air unit has failed or

is too weak.

▸ Check purge air unit

▸ Plan redundant purge air unit.

▸ Strengthen purge air unit.

Table 16: Error diagnosis - sample gas penetrating

Error Possible causes Remedy

Corrosion on probe, filter

cuvettes (GPP) or flanges

● Unsuitable materials

▸ Check project planning.

Table 17: Error diagnosis - corrosion on flange

Status, see page 44

Message number/

number of messages

Date (dd/mm)

Time (hh:mm:ss)

Initiator, footnote, see page 60

Error message, see “Error messages”

Loading...

Loading...