55

8012707/ZVF9/V2-1/2019-04 | SICK OPERATING INSTRUCTIONS | GM32

Subject to change without notice

CLEARING MALFUNCTIONS 7

7.2 Error diagnosis Tables

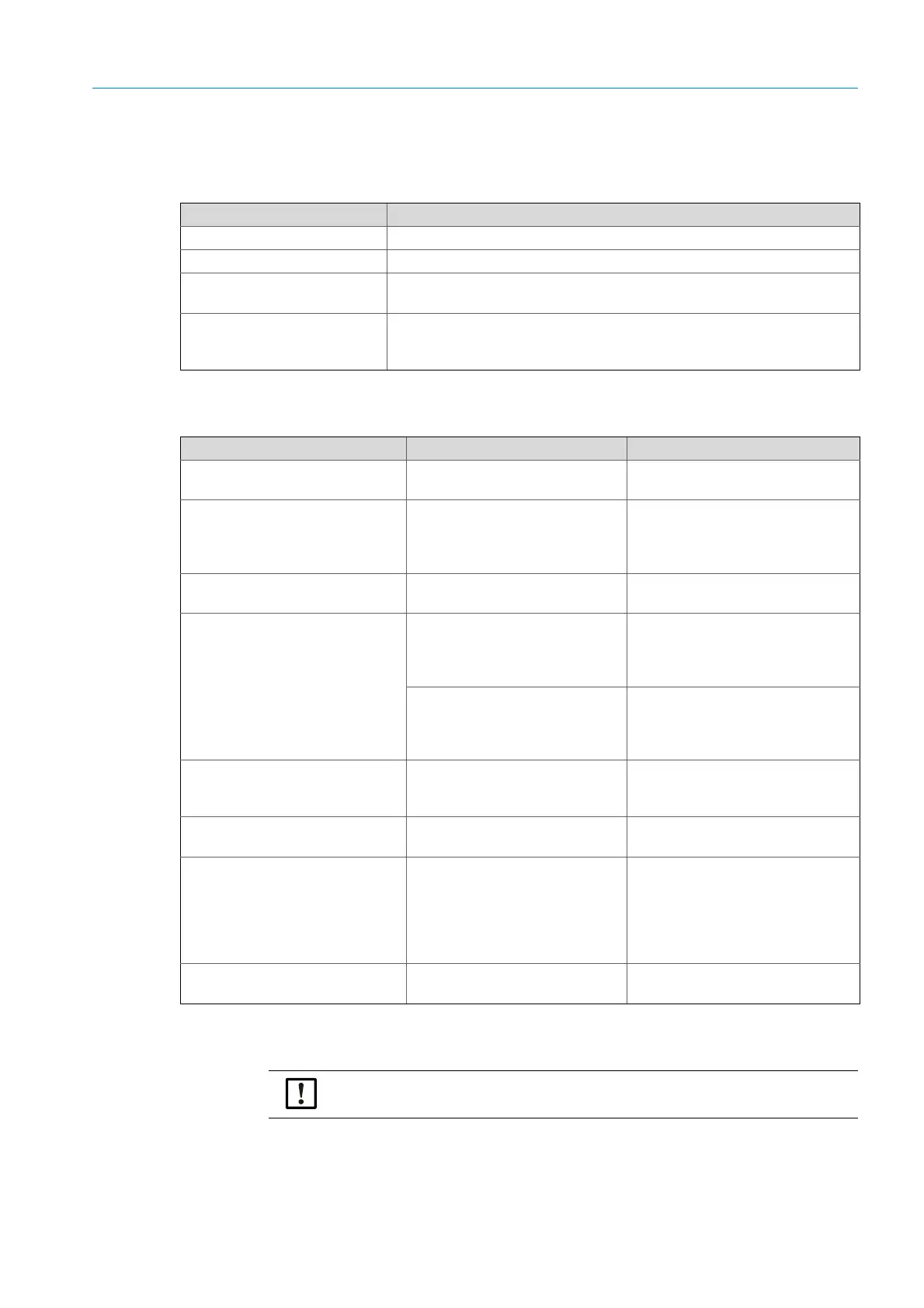

7.2.1 Device not functioning

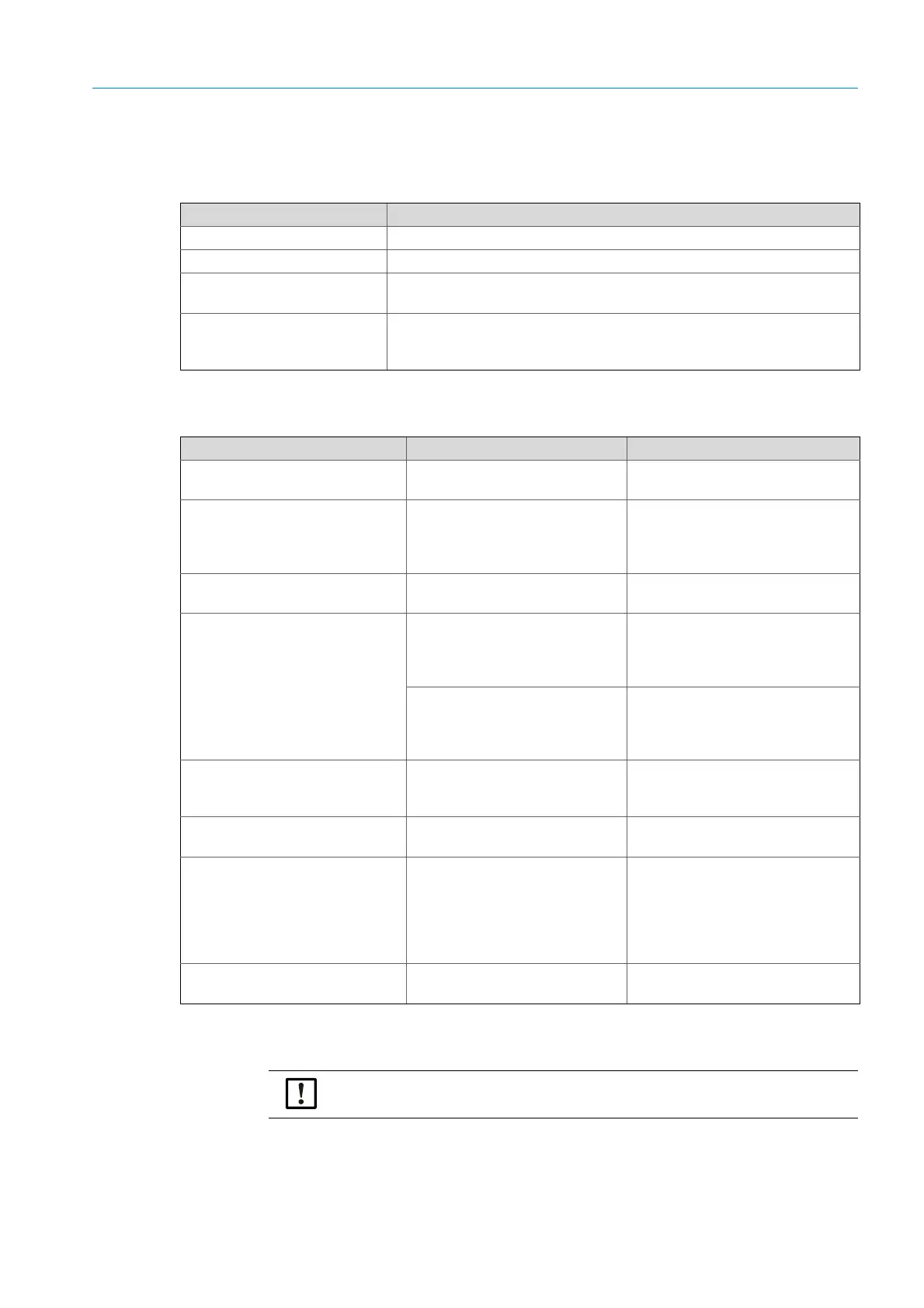

7.2.2 Measured values clearly incorrect

7.2.3 Sample gas penetrating

Possible causes Information

Power supply not connected.

▸ Check power cable and connections.

Main power supply has failed.

▸ Check power supply (e.g. socket, external disconnecting device).

Internal operating temperatures

not correct.

▸ Check whether error messages exist.

Internal software not functioning.

Can only occur with complex internal malfunctions or after strong external

influences (e.g. strong electromagnetic interfering pulse).

▸ Swítch the GM32 off and back on again after a few seconds.

Table 14: Error diagnosis - device not functioning

Possible errors Possible causes Remedy

Leakages (on GPP probe). ---

▸ Have the GPP probe checked by

SICK Customer Service.

Sample gas penetrated the area

before the SR-unit.

● Gas pressure in gas duct too

high.

● Purge air unit has failed or is too

weak.

▸ see “Sample gas penetrating”,

page 55.

For GPP probe: Temperature dropped

below dewpoint.

---

▸ Check project planning.

Sample gas penetrates the purge air

compartment.

● Gas pressure in gas duct too

high.

● Purge air unit has failed or is too

weak.

▸ see “Sample gas penetrating”,

page 55.

● Probe gap alignment incorrect.

Sample gas flow must not

pressed into the purge air

openings.

▸ Check installation.

Sample gas conditions do not match,

or no longer match, project planning.

● Plant condition has changed ▸ Check sample gas conditions

(temperature, moisture,

concentration etc.).

GM32 not ready for operation. ---

▸ Check start-up

▸ Check status/error messages.

GM32 calibration is not correct. ---

Check:

Were correct test gases used?

Are setpoint values correct?

If this does not help: Carry out a

calibration (please contact SICK

Service).

Analyzer is contaminated. ---

Report to manufacturer's Technical

Service or trained skilled persons.

Table 15: Error diagnosis - incorrect measured values

NOTE: Sample gas in the analyzer can damage the analyzer.

Loading...

Loading...