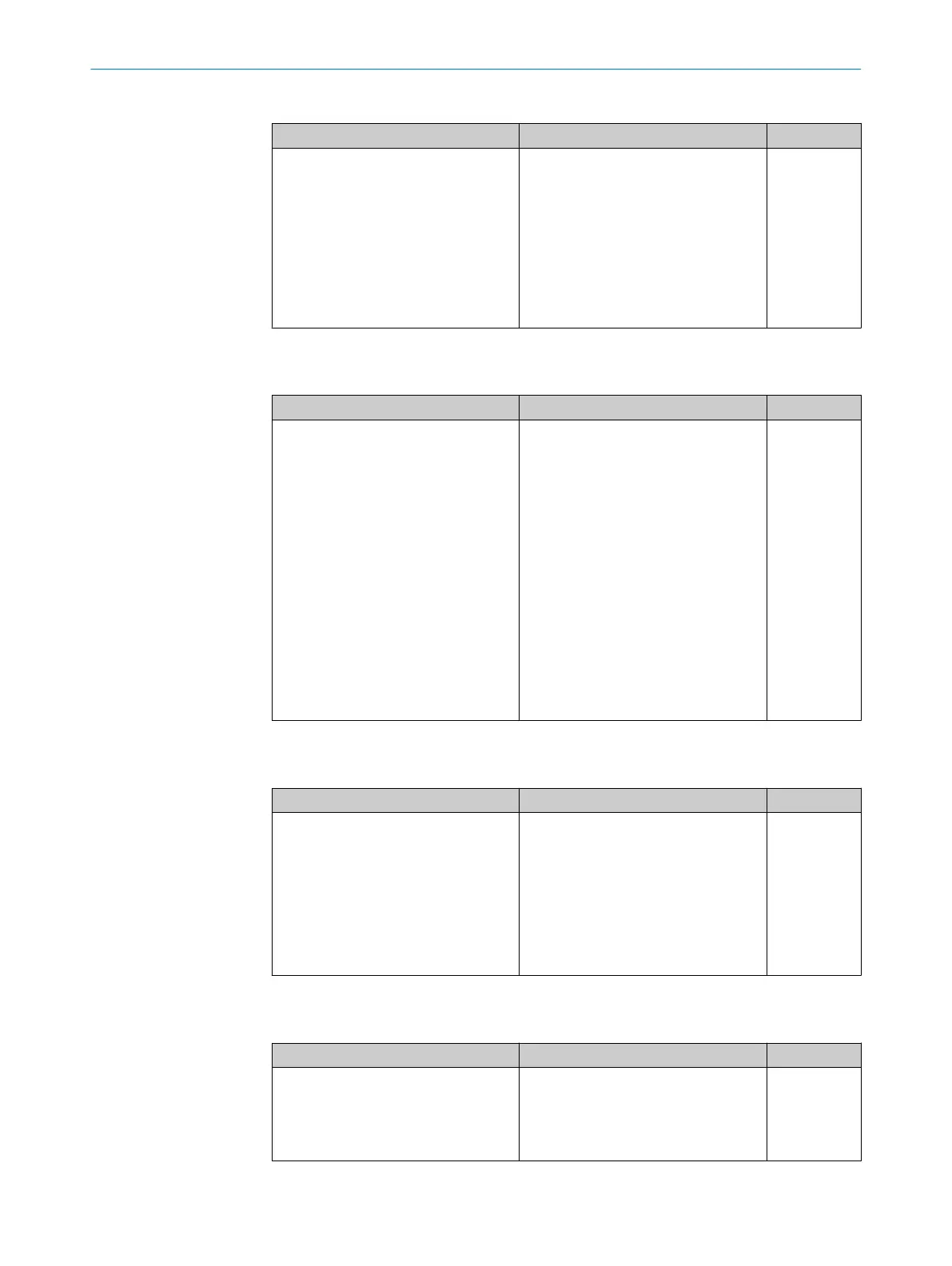

Table 106: Mounting

Check sequence Expected result Result OK?

1. Check the mounting of the safety

s

ystem.

•

T

he sensor system has been

mounted in accordance with these

operating instructions.

•

The sensor system must be

mounted within a permissible dis‐

tance of the bar code tape

(80 mm-120 mm).

•

There are no signs of manipulation

as far as the mounting is con‐

cerned.

Yes N

o

Electrical installation

T

able 107: Cable laying

Check sequence Expected result Result OK?

1. Check the cable laying.

•

T

he approved X-junction and, if

required, the permitted connection

cables from SICK are the only

options that can be used for electri‐

cally connecting the OLM sensors.

•

The X-junction is wired from the

FX3-MOC1 connector plug to the

SSI splitter within an electrical

installation area.

•

The maximum permitted lengths

have not been exceeded for cables.

•

The connector plugs for the OLM

sensors are mechanically secured

with tightened M12 threaded rings.

•

The connector plug for the FX3-

MOC1 is mechanically secured with

two screws (in the plug).

Yes N

o

Product description

T

able 108: Components

Check sequence Expected result Result OK?

1. Check that only approved OLM

sensor

s with the safety controller

have been used.

•

Onl

y the approved full OLM sensor

system has been used.

•

Individual sensors have not been

exchanged. The sensor system may

only be exchanged as one whole

unit (i.e., a mounting bracket with

sensors mounted on it).

•

The sensor system is only operated

with a Flexi Soft safety controller.

Yes N

o

Ambient conditions

T

able 109: Surrounding area

Check sequence Expected result Result OK?

1. Check the safety system for

manipula

tions in the surrounding

area.

•

T

here are no signs of manipulation

in the surrounding area, e.g., a bar

code having been affixed in front of

the sensors or dazzle from ambient

light.

Yes N

o

17 ANNEX

94

O P E R A T I N G I N S T R U C T I O N S | Safe Linear Positioning 8020941/12O9/2019-08-05 | SICK

Subject to change without notice

Loading...

Loading...