Protection zones

3.3 Checking for protection zone violation, working area limitation and software limits (CALCPOSI)

Job planning

Programming Manual, 07/2010, 6FC5398-2BP40-0BA0

231

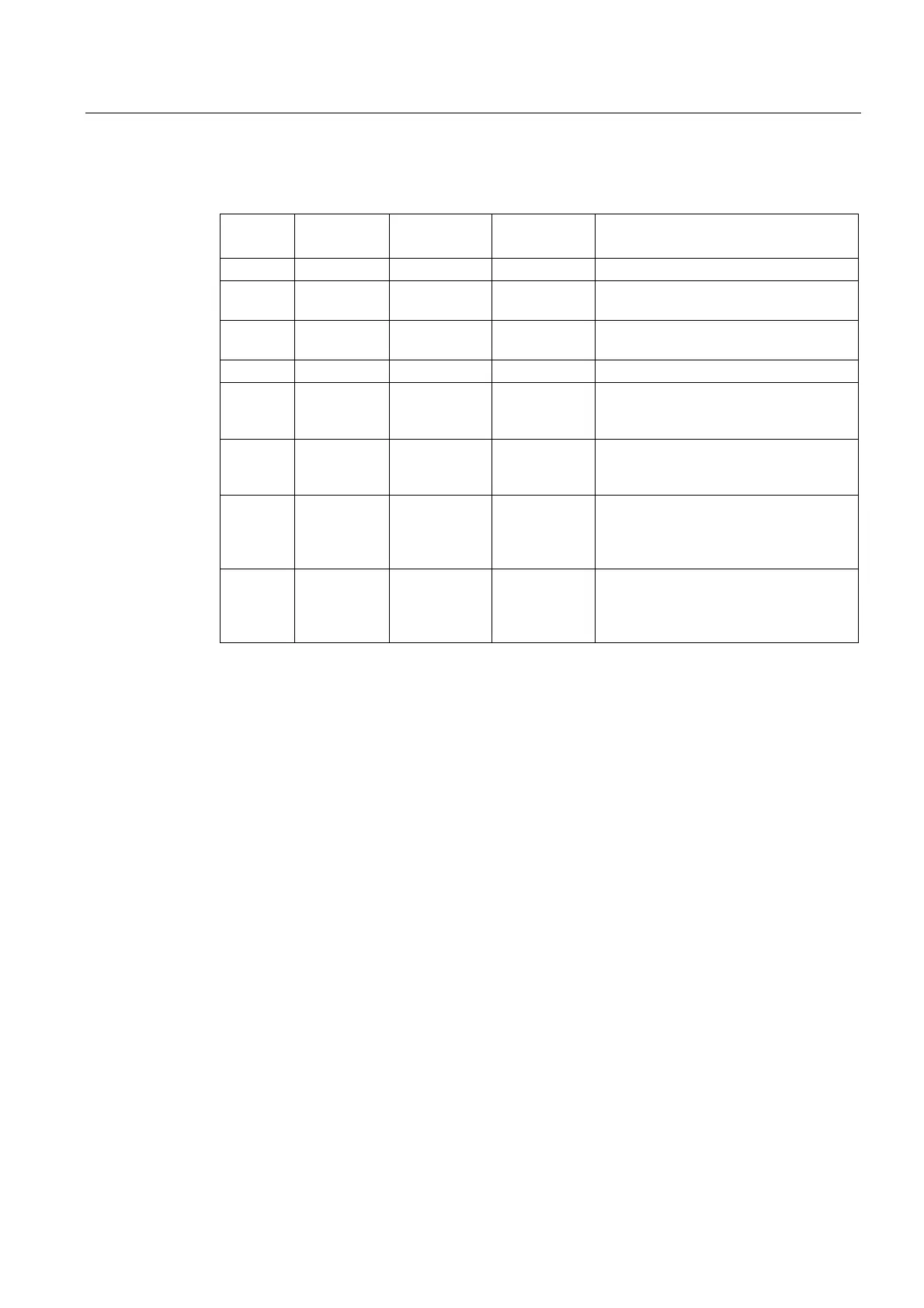

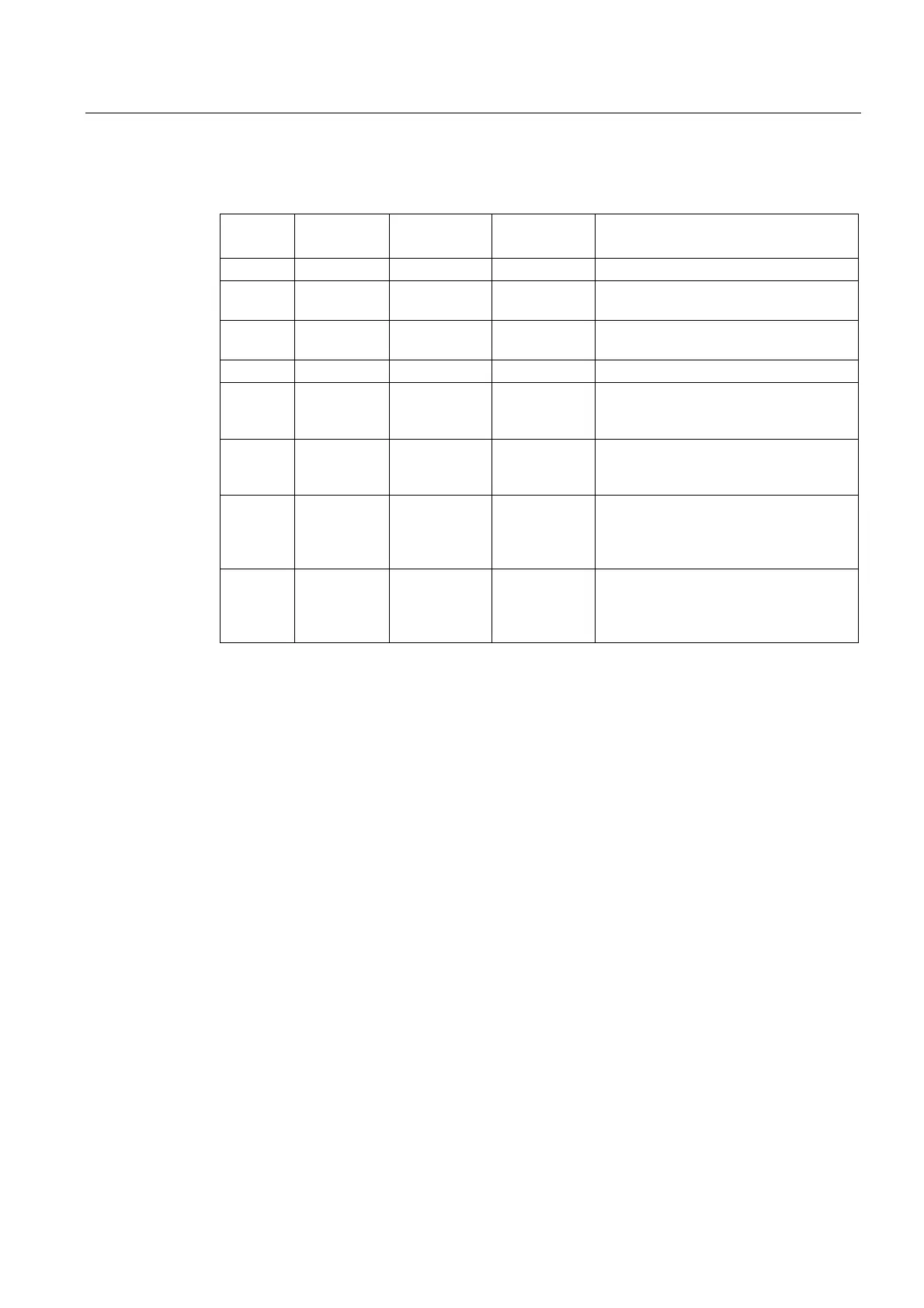

Results of the tests in the example:

Block No.

N...

_STATUS _MAXDIST

[0] (= X)

_MAXDIST

[1] (= Y)

Remarks

420 3123 8.040 4.594 Protection zone SB N3 violated.

430 1122 20.000 11.429 No protection zone monitoring, working

area limits violated.

440 1121 30.000 17.143 Now only monitoring of the software

limits active.

510 4213 0.000 0.000 Starting point violates protection C4

520 0000 0.000 –.000 Pre-activated protection zone C4 is not

monitored. Defined path can be

traversed completely.

540 2222 0.000 –.000 Because _DLIMIT[1]=2, the traversing

path is restricted by the working area

limits.

620 4223 –.000 0.000 Clearance to C4 is a total of 4 mm due

to C2 and _DLIMIT[3]. Clearance C2 –

N3 of 0.1 mm does not lead to limiting

the traversing path.

710 1221 0.000 21.213 Frame with translation and rotation

active The permissible traversing path in

_MOVDIST applies in the shifted and

rotated coordinate system (WCS).

Special cases and further details

All path data are always entered as radii even if for a facing axis with active G code

"DIAMON". If the part of one of the involved axes cannot be traversed completely, the paths

of the other axes will also be reduced accordingly in the _MAXDIST return value so that the

resulting end point lies on the specified path.

It is permissible that no software limits, operating range limits or protection zones are defined

for one or more of the axes involved. All limits are only monitored if the axes involved are

referenced. Any involved rotary axes are monitored only if they are not modulo axes.

As in the normal traversing operation, the monitoring of the software limits and the operating

range limits depends on the active settings (interface signals for selecting the software limits

1 or software limits 2, GWALIMON/WALIMOF, setting data for the specific activation of the

operating range limits and for the specification whether or not the radius of the active tool is

to be considered for the monitoring of the operating range limits).

For certain kinematic transformations (e.g. TRANSMIT), the position of the machine axes

cannot be determined uniquely from the positions in the workpiece coordinate system (WCS)

(non-uniqueness). In the normal traversing operation, the uniqueness normally results from

the previous history and the condition that a continuous movement in the WCS must

correspond to a continuous movement in the machine axes. When monitoring the software

limits using the CALCPOSI function, the current machine position is therefore used to

resolve non-unique determinability in such cases. If necessary, a STOPRE must be

programmed in front of CALCPOSI to input valid machine axis positions to the function.

Loading...

Loading...