Motion synchronous actions

10.7 Control behavior in specific operating states

Job planning

630 Programming Manual, 07/2010, 6FC5398-2BP40-0BA0

10.7 Control behavior in specific operating states

POWER ON

No synchronized actions are ever active during POWER ON. Static synchronized actions

can be activated by an asynchronized subprogram (

ASUB) started by the PLC.

Mode change

Synchronized actions activated by keyword IDS remain active after a change in operating

mode. All other synchronized actions become inactive on a change in operating mode (e.g.

axis positioning) and are reactivated following repositioning and a return to automatic mode.

RESET

An NC reset terminates all non-modal and modal synchronized actions. Static synchronized

actions remain active. They can start new actions. If a command axis movement is active on

RESET, this is canceled. Previously executed synchronized actions of the WHEN type are

not processed again after RESET.

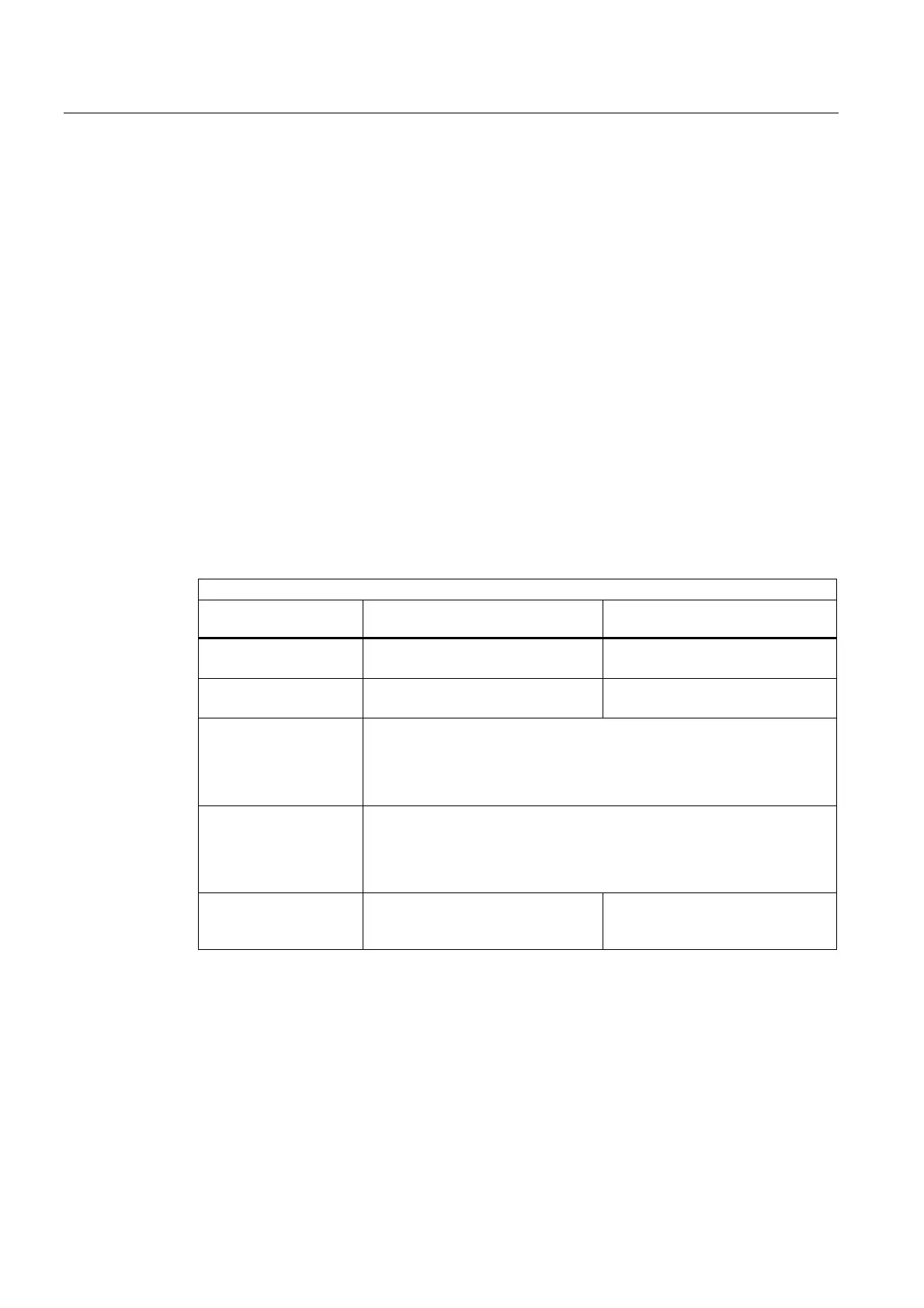

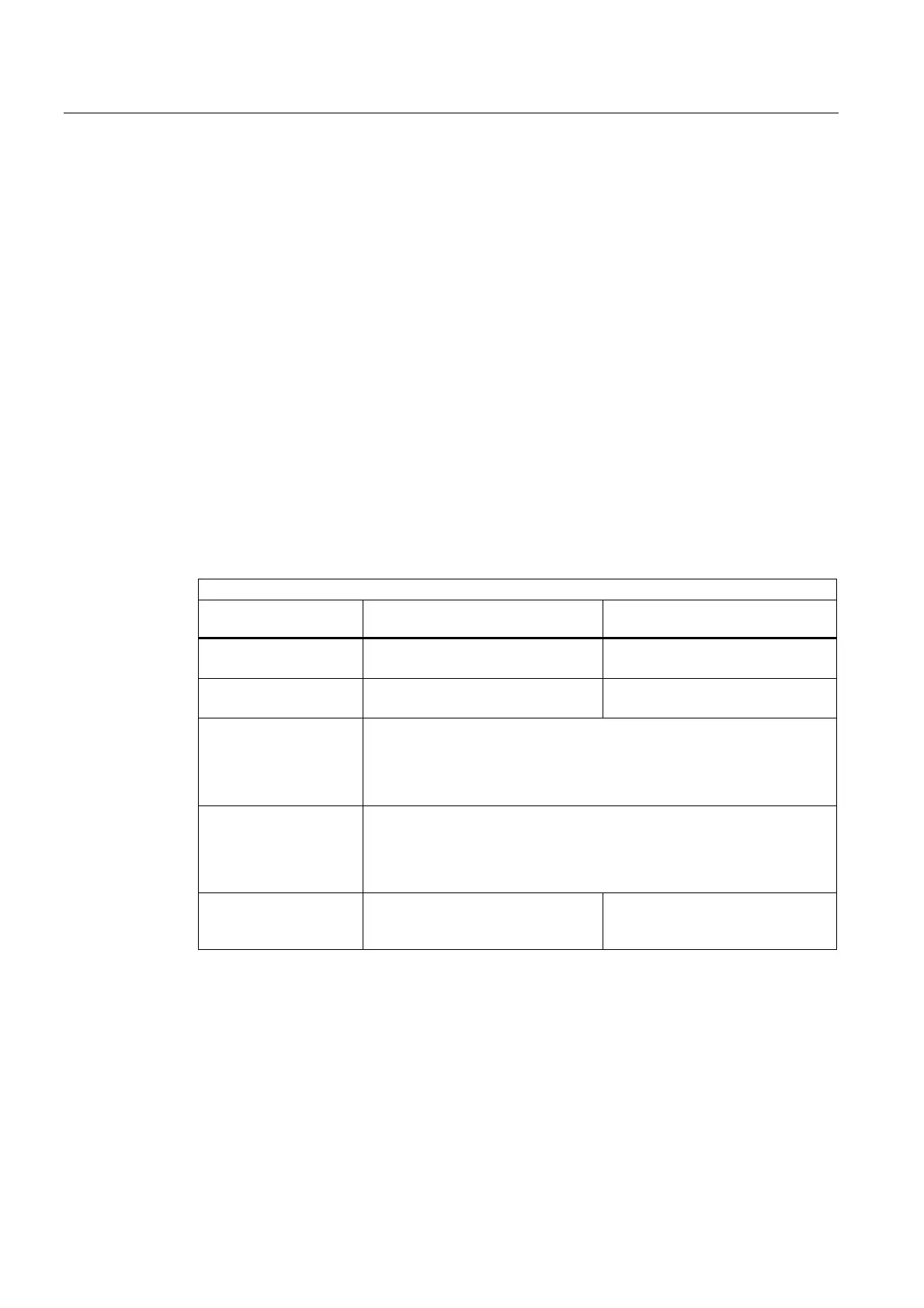

Response following RESET

Synchronized action/

technology cycle

Modal/non-modal Static (IDS)

Active action is canceled,

synchronized actions are deleted.

Active action is canceled,

technology cycle is reset.

Axis/

positioning spindle

Motion is canceled. Motion is canceled.

Speed-controlled

spindle

$MA_SPIND_ACTIVE_AFTER_RESET==1:

Spindle remains active

$MA_SPIND_ACTIVE_AFTER_RESET==0:

Spindle stops.

Master value coupling $MC_RESET_MODE_MASK, bit13 == 1:

Master value coupling remains active

$MC_RESET_MODE_MASK, bit13 == 0:

Master value coupling is separated

Measuring operations Measuring processes started from

synchronized actions are canceled.

Measuring processes started from

static synchronized actions are

canceled.

NC Stop

Static synchronized actions remain active for NC stop. Movements started from static

synchronized actions are not canceled. Synchronized actions that are local to the program

and belong to the active block remain active, movements started from them are stopped.

Loading...

Loading...