Additional functions

14.9 Program runtime/part counter

Job planning

Programming Manual, 07/2010, 6FC5398-2BP40-0BA0

687

14.9.3 Workpiece counter

Function

The "Workpiece counter" function makes available various counters which can be used in

particular internally in the control to count workpieces.

The counters exist as channel-specific system variables with read and write access in a

range of values from 0 to 999,999,999.

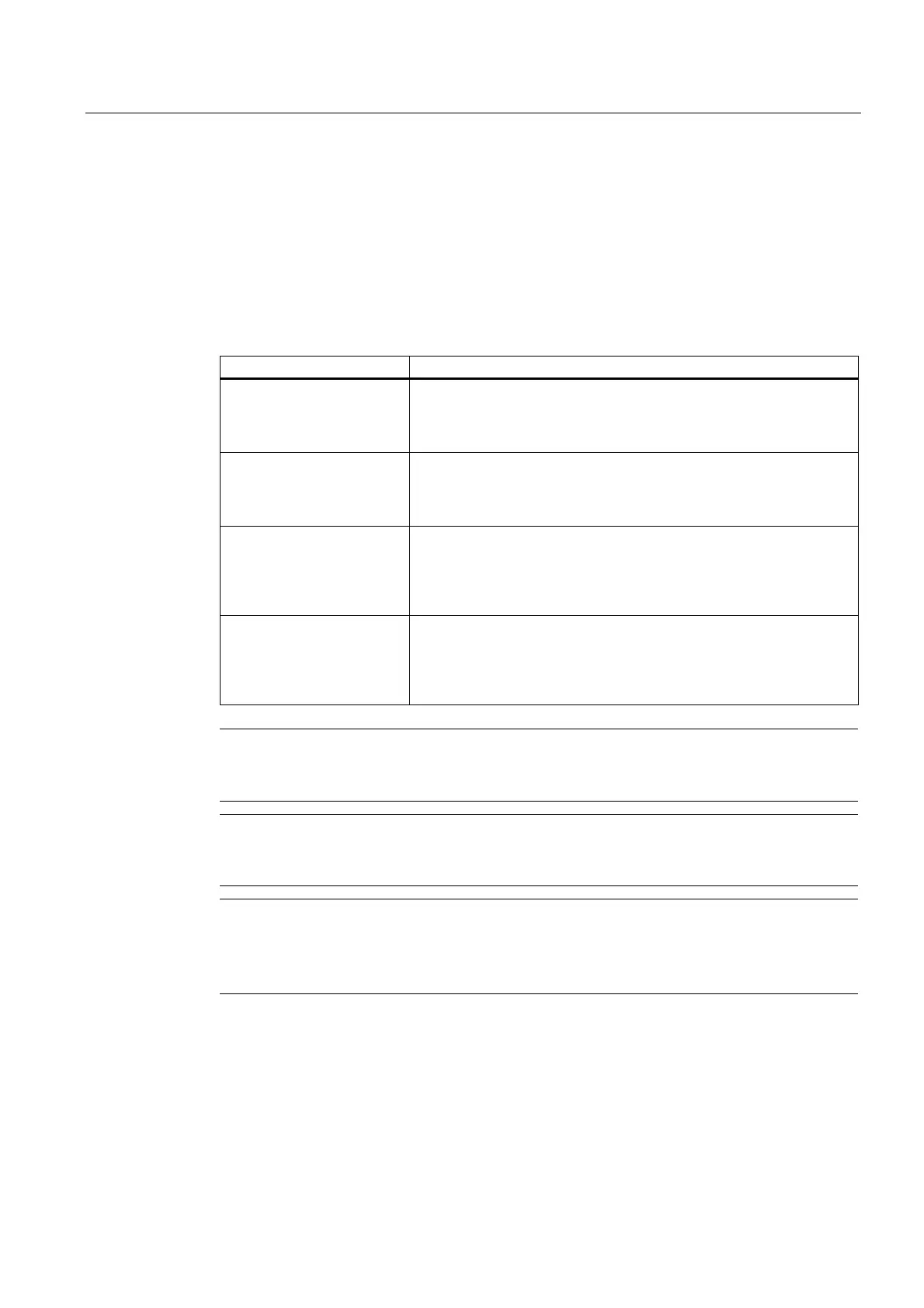

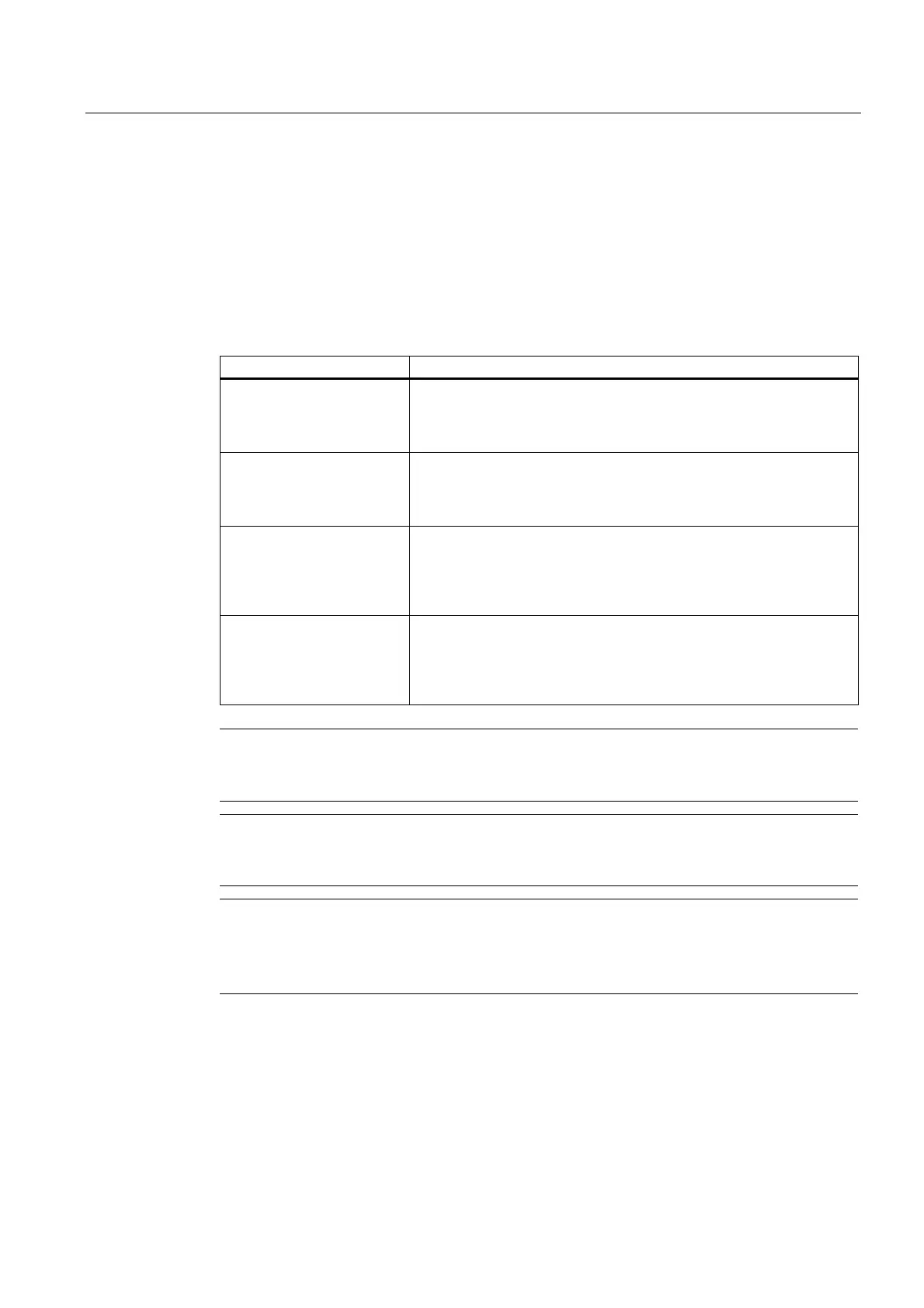

System variable Significance

$AC_REQUIRED_PARTS Number of workpieces to be produced (setpoint number of

workpieces)

In this counter the number of workpieces at which the actual workpiece

count ($AC_ACTUAL_PARTS) will be reset to "0" can be defined.

$AC_TOTAL_PARTS Total number of completed workpieces (actual workpiece total)

This counter specifies the total number of all workpieces produced

since the start time. The value is only automatically reset to "0" when

the control powers up with default values.

$AC_ACTUAL_PARTS Number of completed workpieces (actual workpiece total)

This counter registers the total number of all workpieces produced

since the start time. On condition that $AC_REQUIRED_PARTS > 0,

the counter is automatically reset to "0" when the required number of

workpieces ($AC_REQUIRED_PARTS) is reached.

$AC_SPECIAL_PARTS Number of workpieces selected by the user

This counter supports user-specific workpiece counts. An alarm can be

defined to be output when the setpoint number of workpieces is

reached ($AC_REQUIRED_PARTS). Users must reset the counter

themselves.

Note

ll workpiece counters are set to "0" when the control powers up with default values and can

be read and written independent of their activation.

Note

Channel-specific machine data can be used to control counter activation, counter reset

timing and the counting algorithm.

Note

Workpiece counting with user-defined M command

Machine data can be set so that the count pulses for the various workpiece counters are

triggered using user-defined M commands rather than the end of the program (

M2/M30).

References

For further information about the "Workpiece counter" function see:

● Function Manual, Basic Functions; BAG, Channel, Program Operation, Reset Response

(K1),Chapter: Workpiece counter

Loading...

Loading...