Transformations

6.8 Kinematic transformation

Job planning

360 Programming Manual, 07/2010, 6FC5398-2BP40-0BA0

6.8 Kinematic transformation

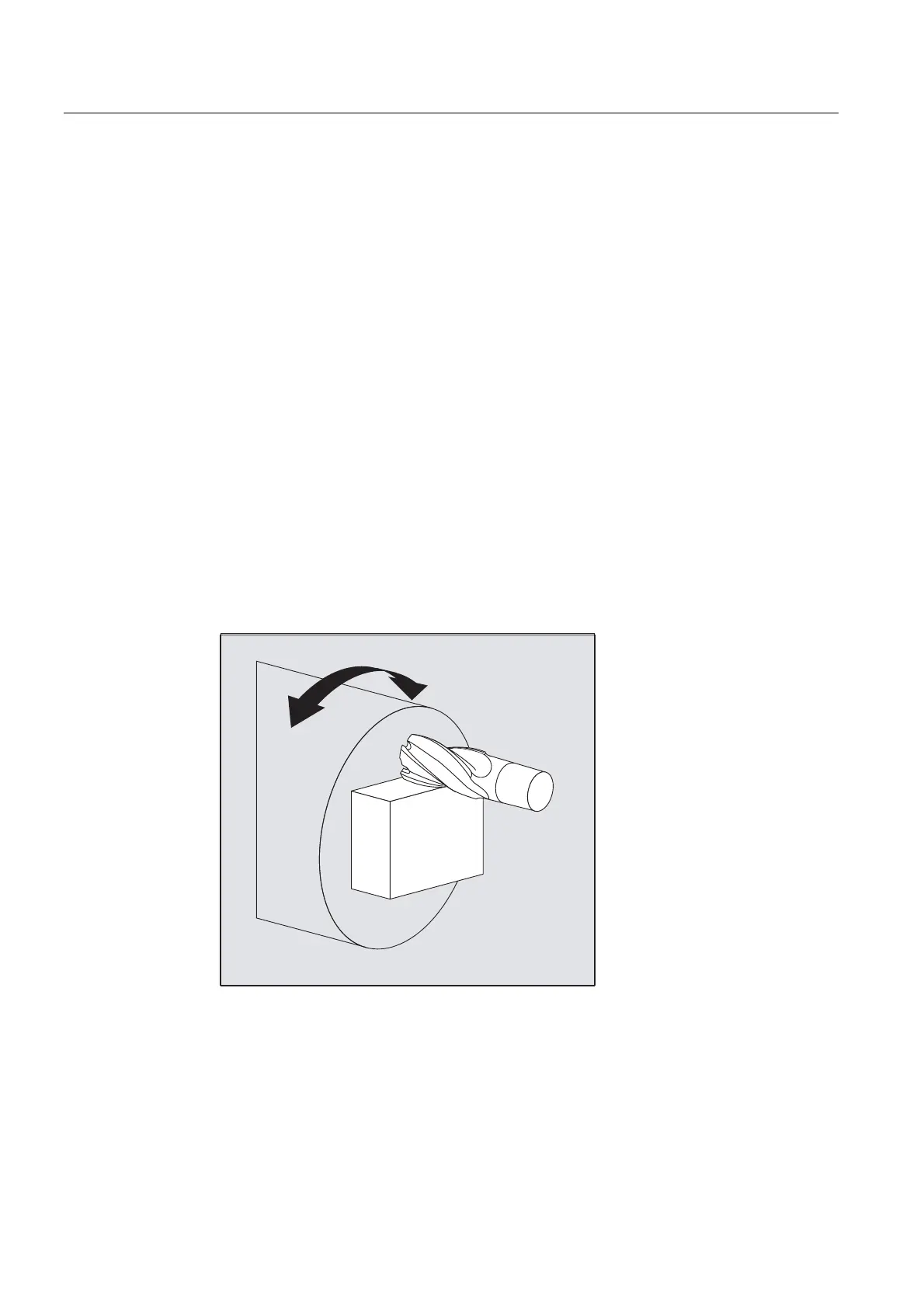

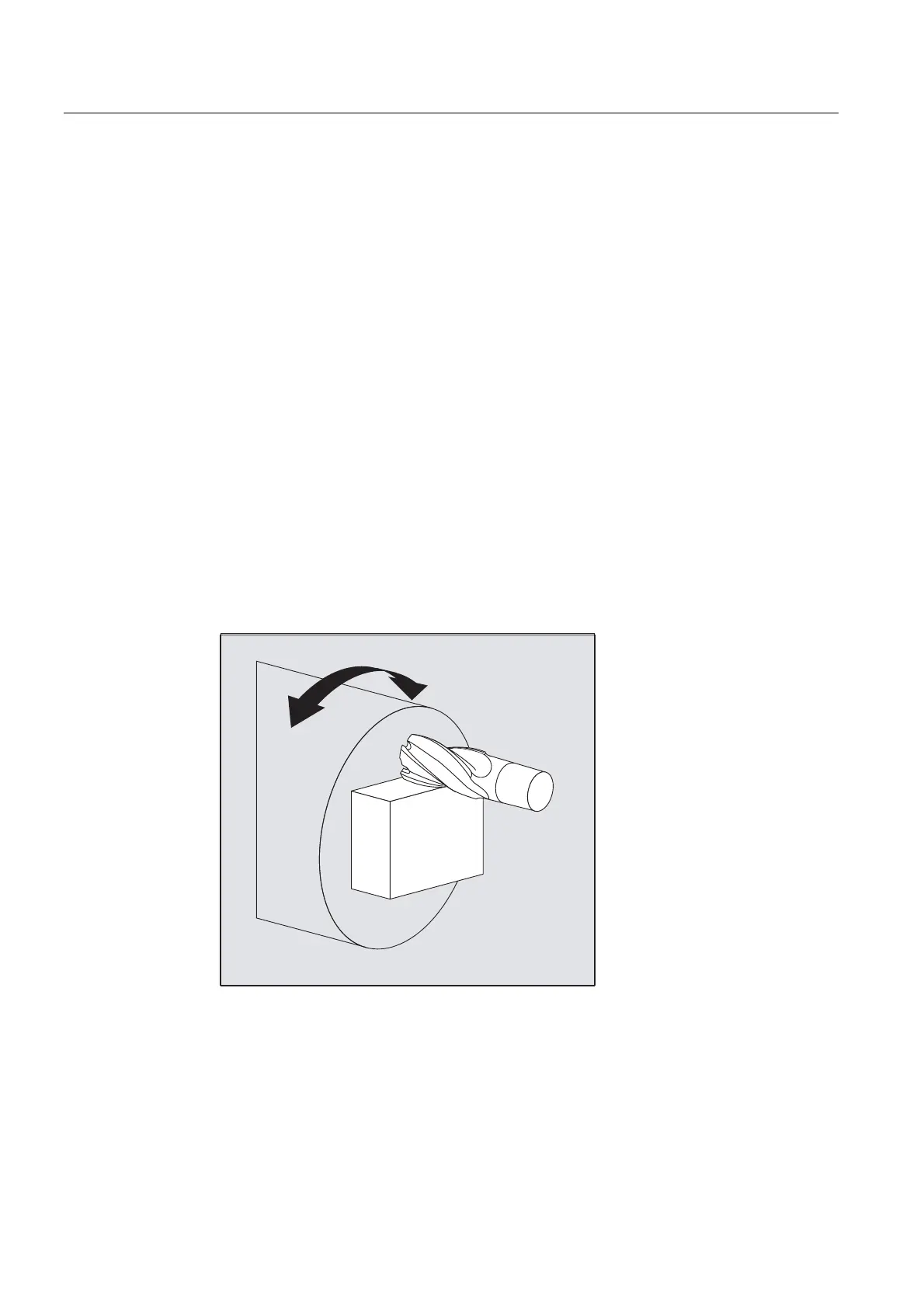

6.8.1 Milling on turned parts (TRANSMIT)

Function

The TRANSMIT function enables the following:

● Face machining on turned parts in the turning clamp (drill-holes, contours).

● A cartesian coordinate system can be used to program these machining operations.

● The control maps the programmed traversing movements of the Cartesian coordinate

system onto the traversing movements of the real machine axes (standard situation):

– Rotary axis

– Infeed axis perpendicular to rotary axis

– Longitudinal axis parallel to rotary axis

– The linear axes are positioned perpendicular to one another.

● A tool center offset relative to the turning center is permitted.

● The velocity control makes allowance for the limits defined for the rotations.

Loading...

Loading...