Transformations

6.8 Kinematic transformation

Job planning

366 Programming Manual, 07/2010, 6FC5398-2BP40-0BA0

Program code Comments

Geometry Radius

$TC_DP6[1,1]=6. Radius Tool radius

$TC_DP7[1,1]=0 Slot width b for slotting

saw, rounding radius for

milling tools

$TC_DP8[1,1]=0 Projection k For slotting saw only

$TC_DP9[1,1]=0

$TC_DP10[1,1]=0

$TC_DP11[1,1]=0 Angle for taper milling

tools

Program code Comments

Wear Tool length and radius

compensation

$TC_DP12[1,1]=0 Remaining parameters to

$TC_DP24=0

Tool base dimension/ adapter

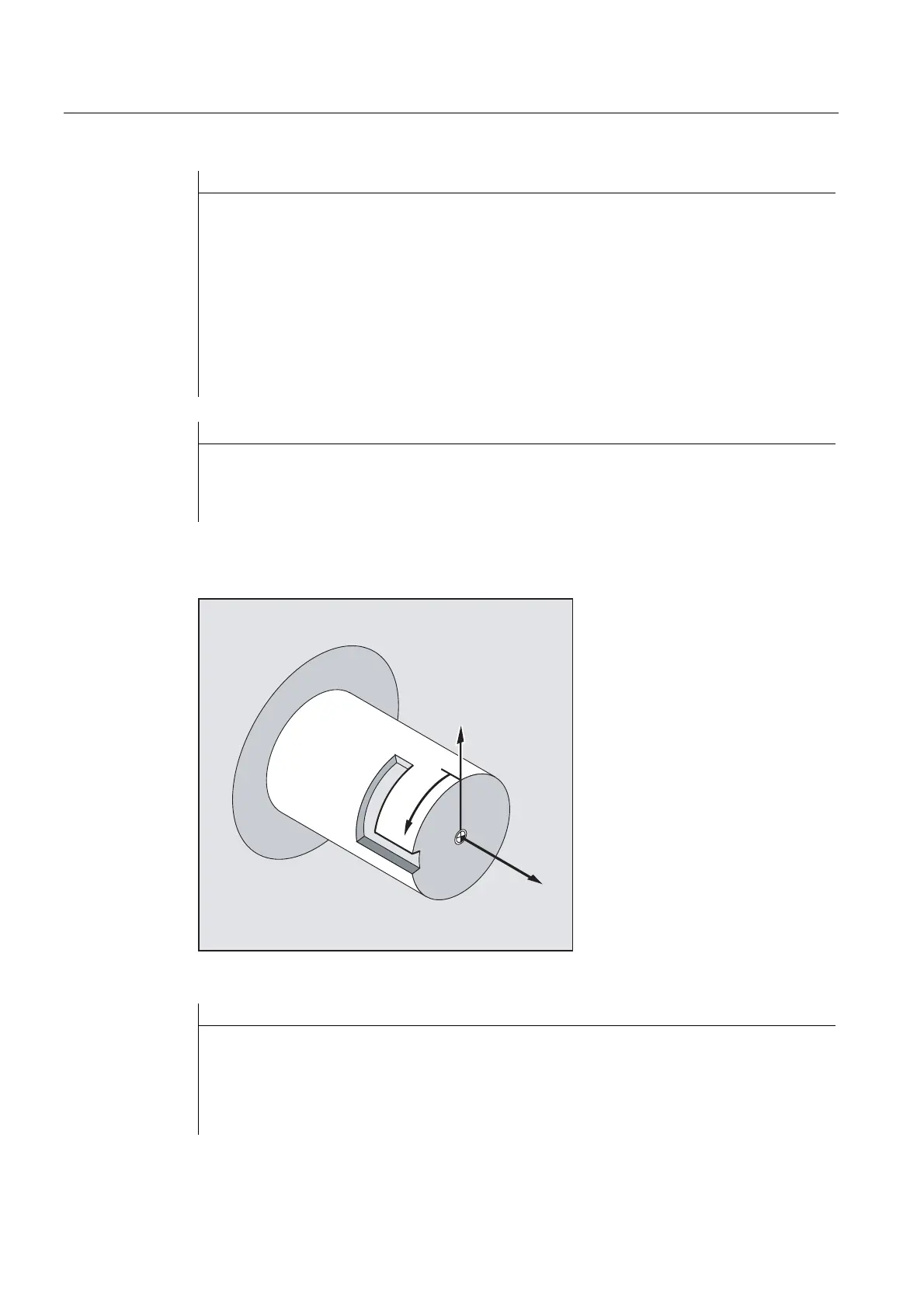

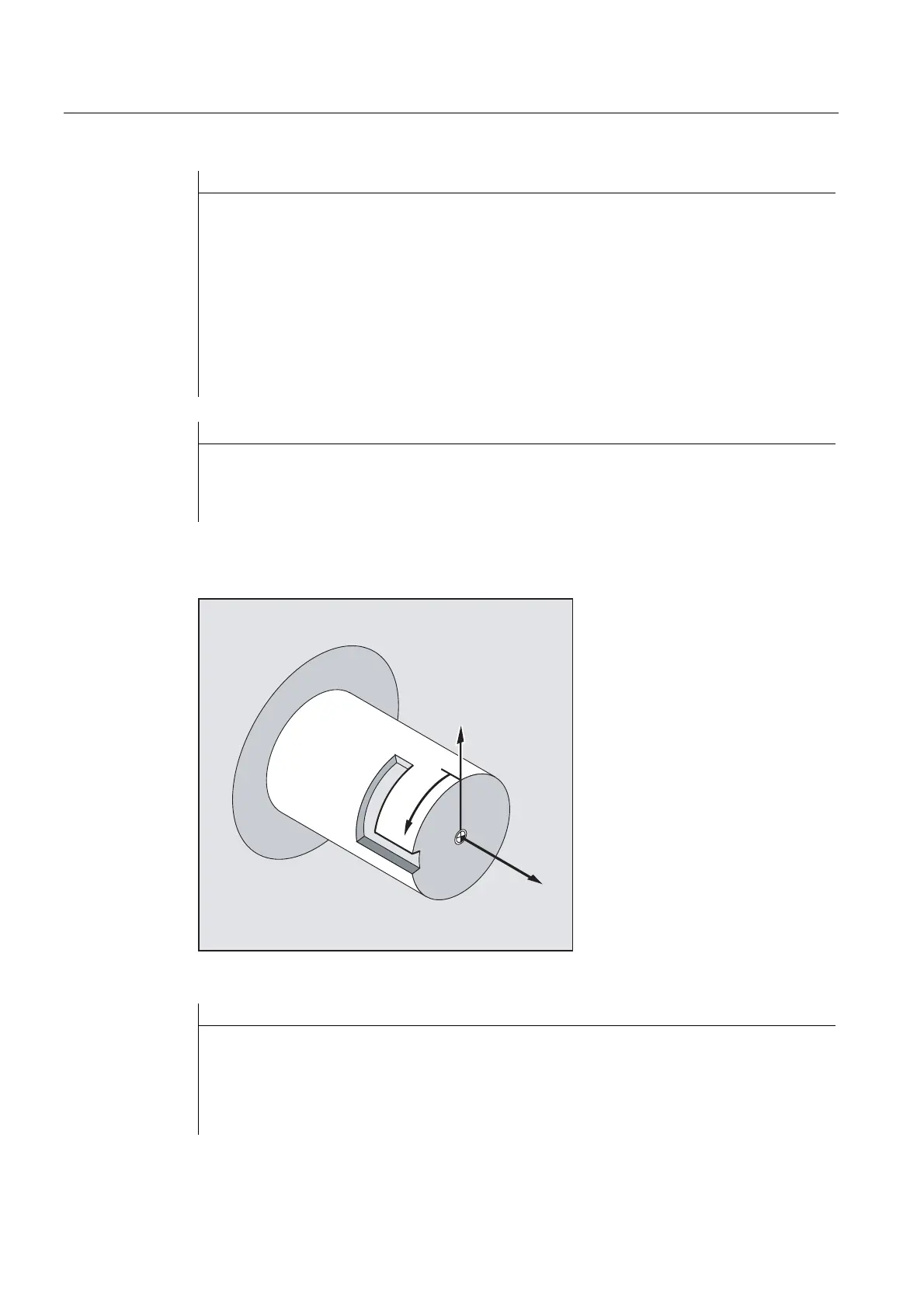

Example: Making a hook-shaped groove

=

<

;

Activate cylinder surface transformation:

Program code Comments

N10 T1 D1 G54 G90 F5000 G94 ; Tool selection, clamping compensation

N20 SPOS=0

N30 G0 X25 Y0 Z105 CC=200

; Approach the starting position

N40 TRACYL (40) ; Activate cylinder surface ;transformation

N50 G19 ; Plane selection

Loading...

Loading...