Tool offsets

7.1 Offset memory

Job planning

Programming Manual, 07/2010, 6FC5398-2BP40-0BA0

391

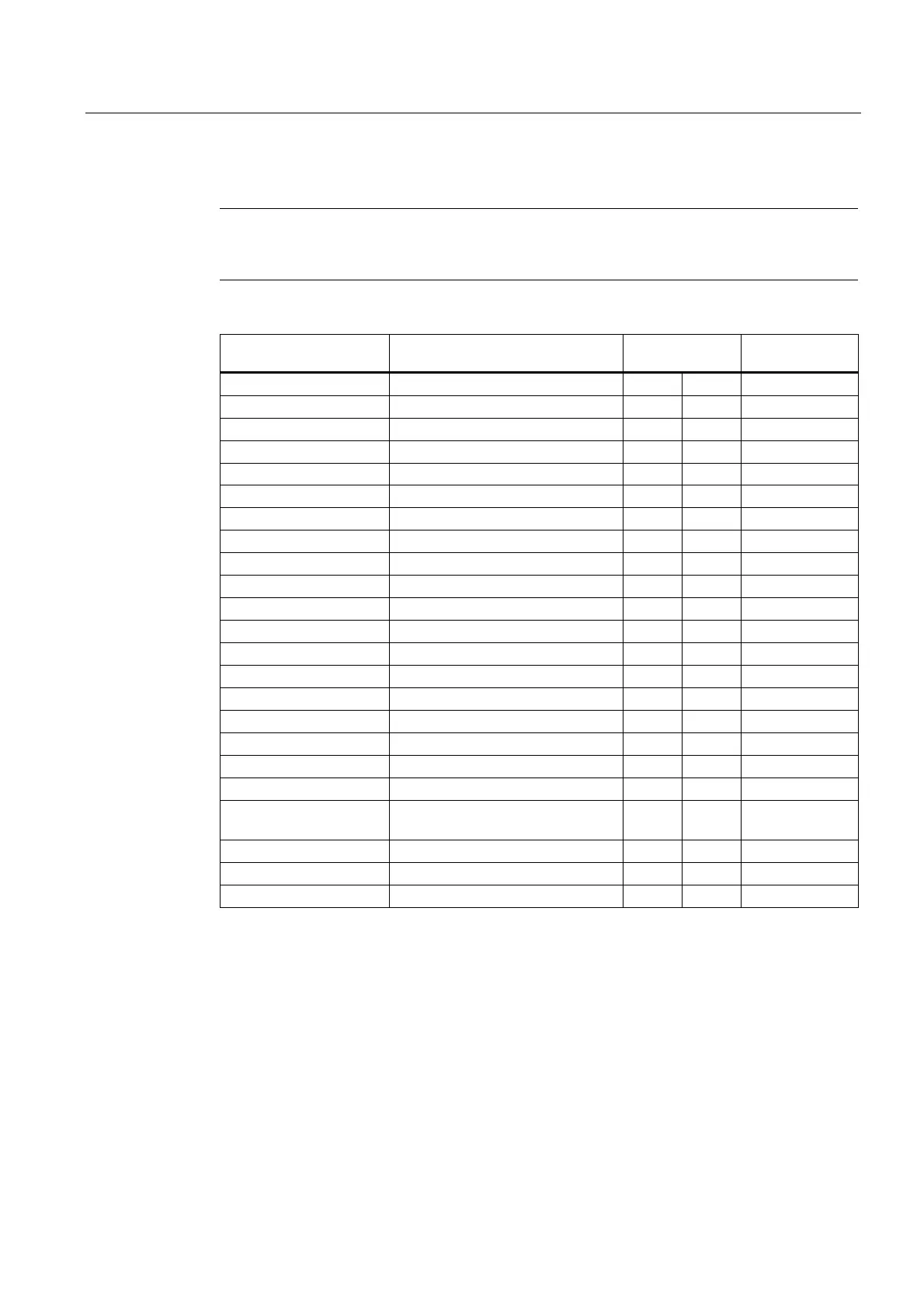

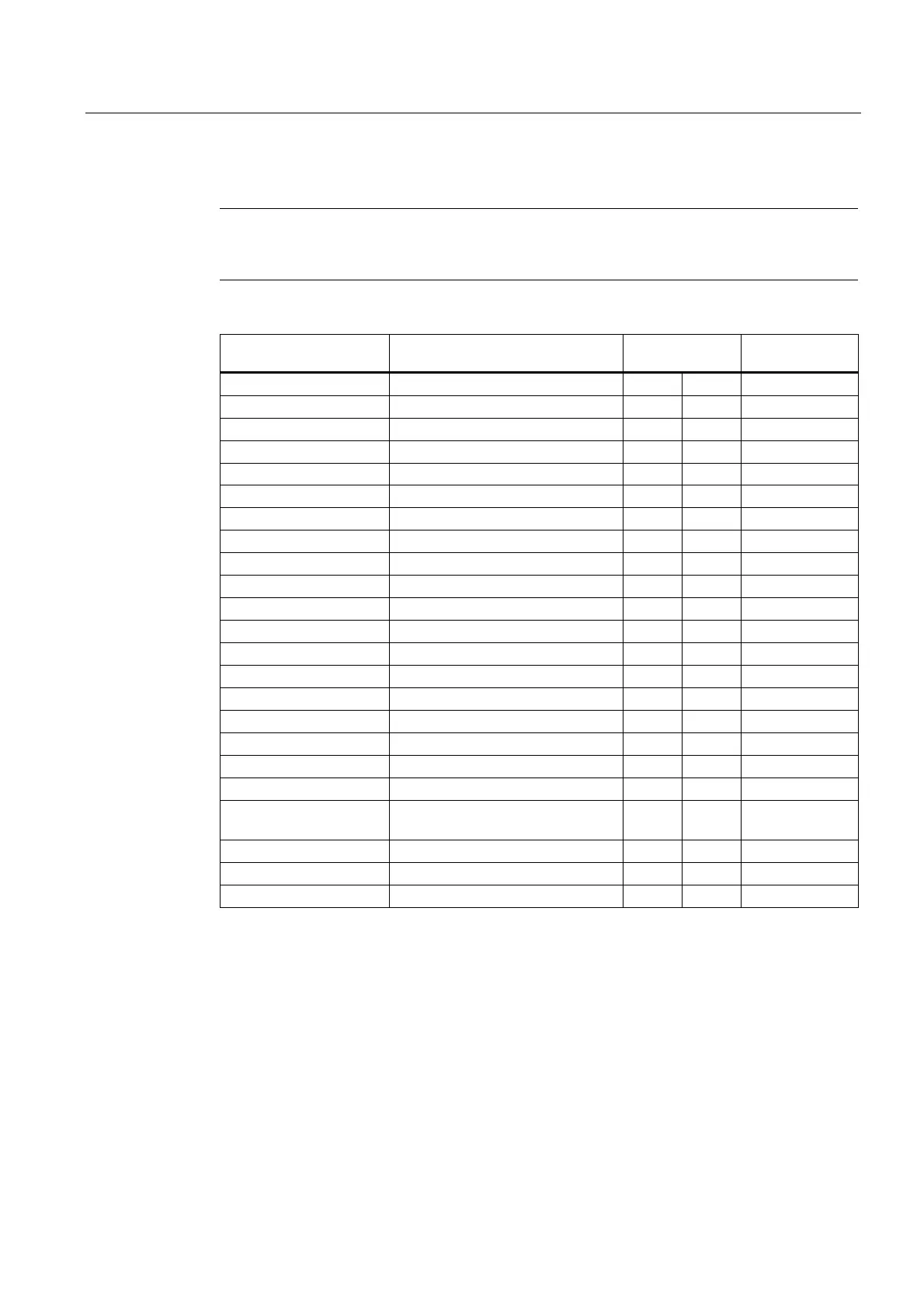

Tool parameters $TC-DP1 to $TC-DP23 with contour tools

Note

The tool parameters not listed in the table, such as $TC_DP7, are not evaluated, i.e. their

content is meaningless.

Tool parameter number

(DP)

Significance Cutting Dn Remarks

$TC_DP1 Tool type 400 ... 599

$TC_DP2 Tool nose position

Geometry Length compensation

$TC_DP3 Length 1

$TC_DP4 Length 2

$TC_DP5 Length 3

Geometry Radius

$TC_DP6 Radius

Geometry Limit angle

$TC_DP10 minimum limit angle

$TC_DP11 maximum limit angle

Wear Length and radius compensation

$TC_DP12 Wear length 1

$TC_DP13 Wear length 2

$TC_DP14 Wear length 3

$TC_DP15 Wear radius

Wear Limit angle

$TC_DP19 Wear min. limit angle

$TC_DP20 Wear max. limit angle

Tool base dimension/

adapter

Length compensations

$TC_DP21 Length 1

$TC_DP22 Length 2

$TC_DP23 Length 3

Basic value and wear value

The resultant values are each a total of the basic value and wear value (e.g. $TC_DP6 +

$TC_DP15 for the radius). The basic measurement ($TC_DP21 – $TC_DP23) is also added

to the tool length of the first cutting edge. All the other parameters, which may also impact on

effective tool length for a standard tool, also affect this tool length (adapter, orientational

toolholder, setting data).

Limit angles 1 and 2

Limit angles 1 and 2 each relate to the vector of the cutting edge center point to the cutting

edge reference point and are counted clockwise.

Loading...

Loading...