Tool offsets

7.3 Special handling of tool offsets

Job planning

Programming Manual, 07/2010, 6FC5398-2BP40-0BA0

401

Further information

Distinguishing features

The most important distinguishing features are shown in the following table:

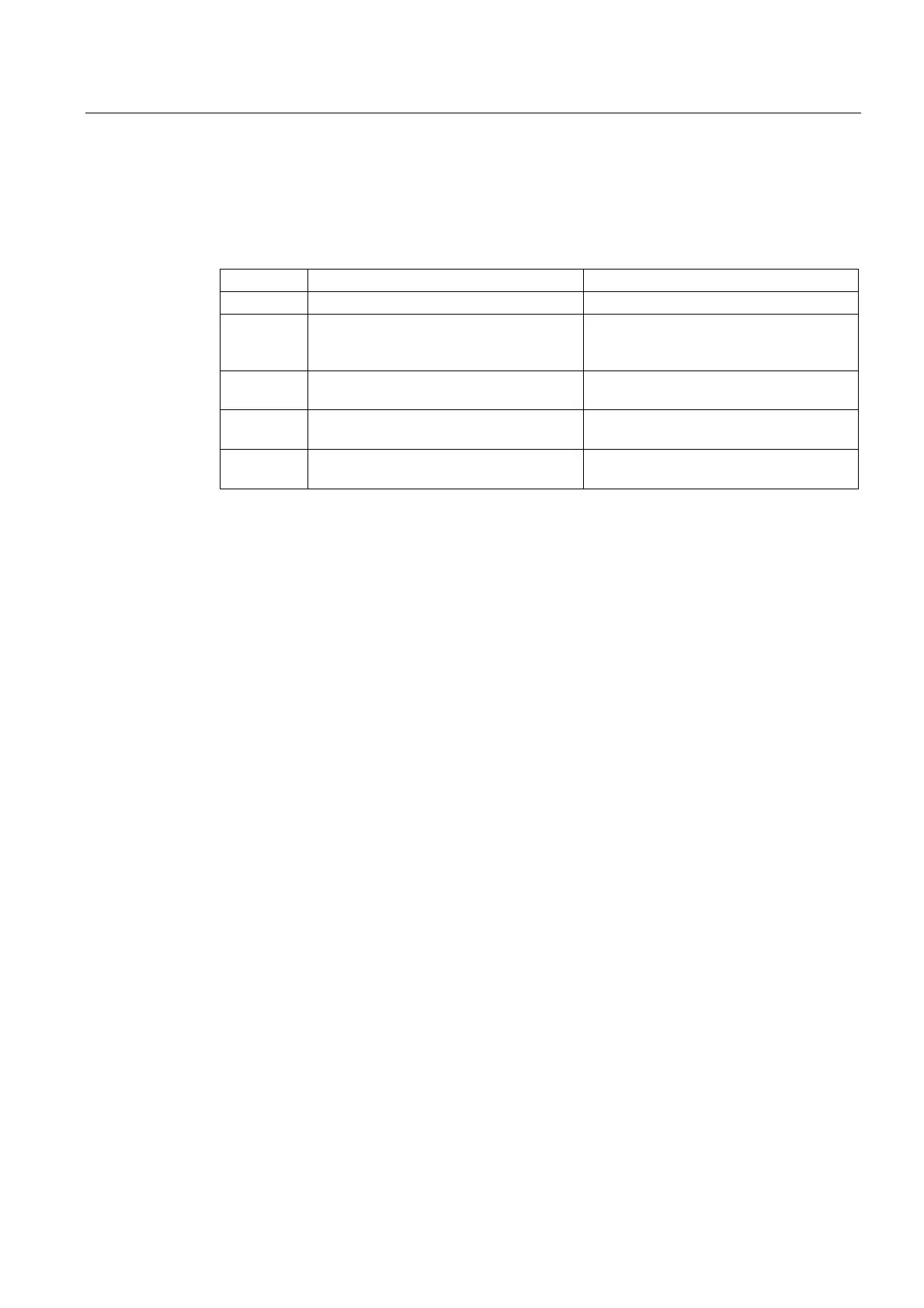

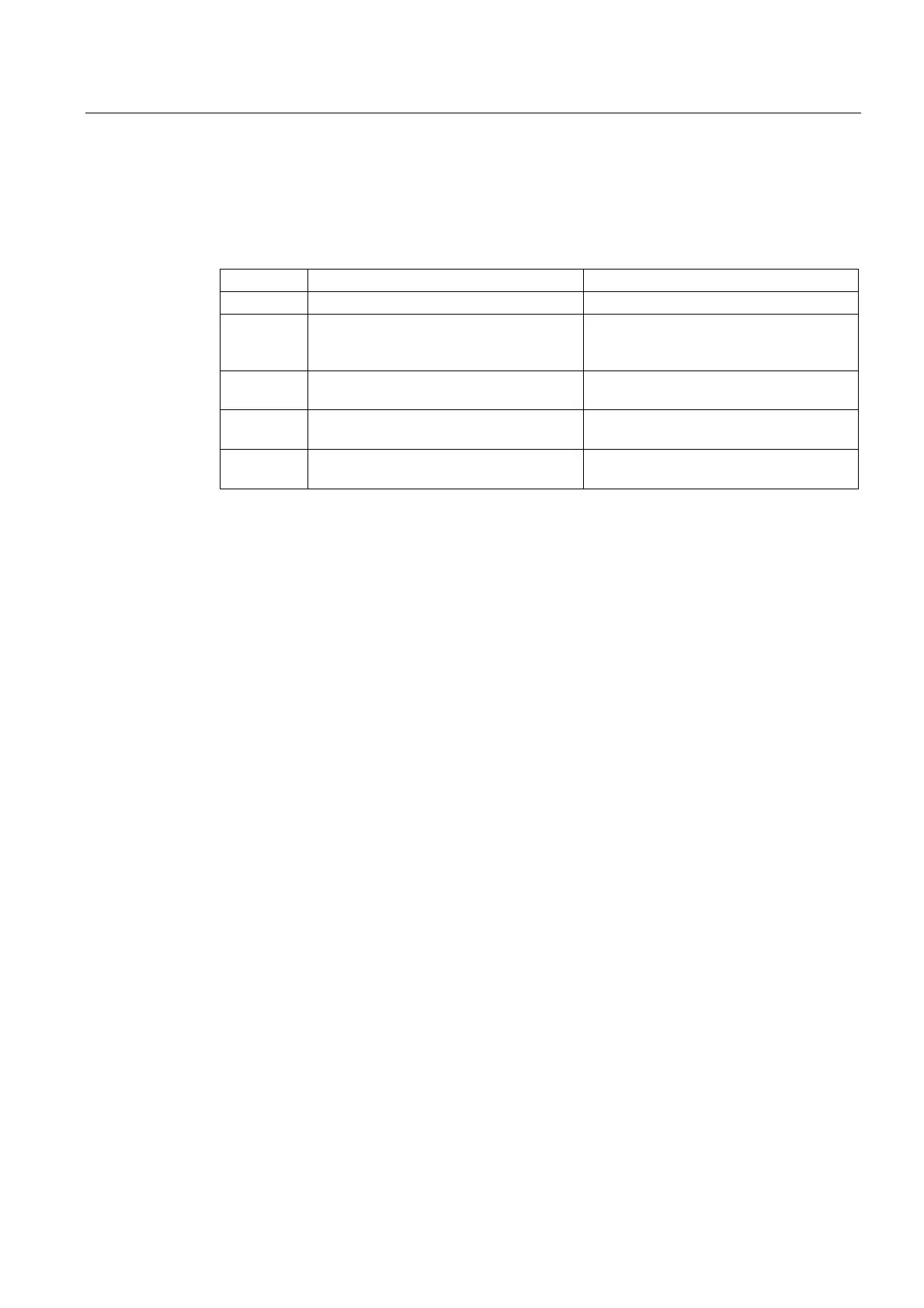

G code Wear value Active orientable toolholder

TOWSTD

Initial value, tool length Wear values are subject to rotation.

TOWMCS

Wear value in MCS.

TOWMCS is identical to

TOWSTD if a tool holder that can be

orientated is not active.

It only rotates the vector of the resultant

tool length without taking into account the

wear.

TOWWCS

The wear value is converted to the MCS in

the WCS.

The tool vector is calculated as for

TOWMCS

without taking into account the wear.

TOWBCS

The wear value is converted to the MCS in

the BCS.

The tool vector is calculated as for

TOWMCS

without taking into account the wear.

TOWTCS

The wear value is converted to the MCS in

the workpiece coordinate system.

The tool vector is calculated as for

TOWMCS

without taking into account the wear.

TOWWCS , TOWBCS, TOWTCS: The wear vector is added to the tool vector.

Linear transformation

The tool length can be defined meaningfully in the MCS only if the MCS is generated by

linear transformation from the BCS.

Non-linear transformation

For example, if with TRANSMIT a non-linear transformation is active, then when specifying

the MCS as requested coordinate system, BCS is automatically used.

No kinematic transformation and no orientable toolholder

If neither a kinematic transformation nor an orientable toolholder is active, then all the other

four coordinate systems (except for the WCS) are combined. It is then only the WCS, which

is different to the other systems. Since only tool lengths need to be evaluated, translations

between the coordinate systems are irrelevant.

References:

For more information on tool compensation, see:

Function Manual Basic Functions; Tool Offset (W1)

Loading...

Loading...