Tool offsets

7.5 Activate 3D tool offsets (CUT3DC..., CUT3DF...)

Job planning

Programming Manual, 07/2010, 6FC5398-2BP40-0BA0

421

Further Information

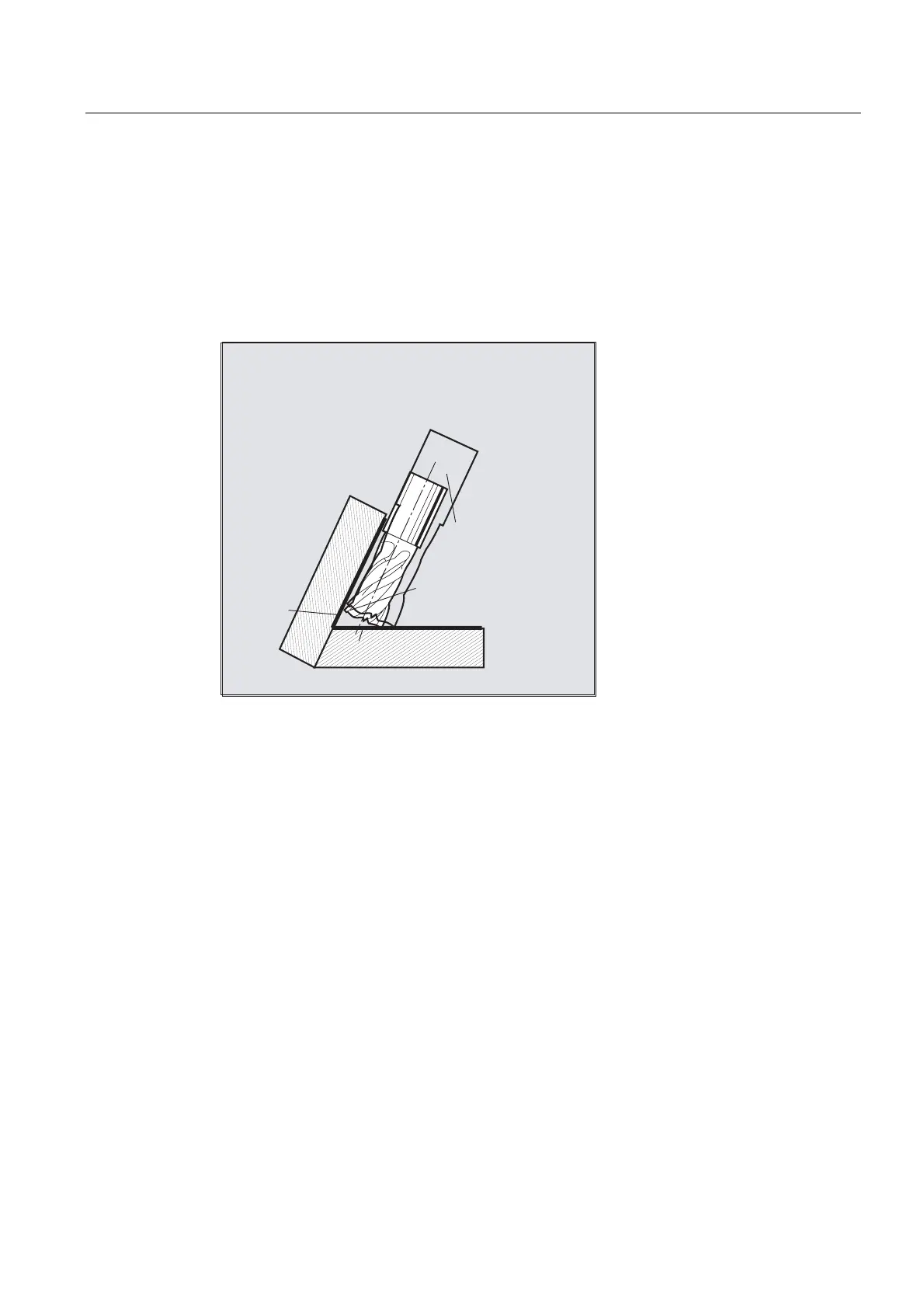

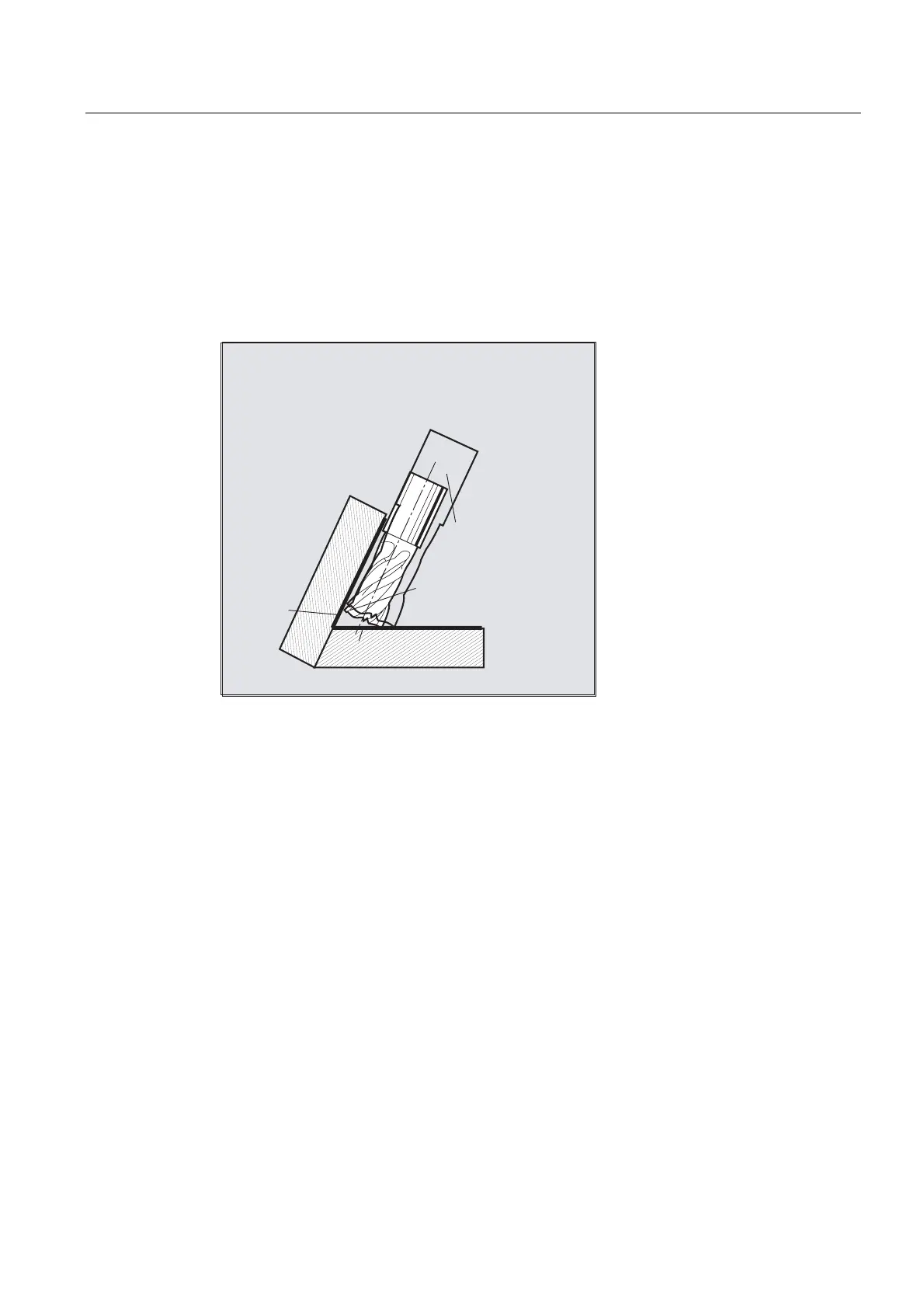

Tool center point path with infeed up to the limitation surface CUT3DCCD

If a tool with a smaller radius than the appropriate standard tool is used, machining is

continued using a milling tool, which is infed in the longitudinal direction until it reaches the

bottom (base) of the pocket. The tool removes as much material from the corner formed by

the machining surface and limitation surface. This involves a machining type combining

circumferential and face milling. Analog to a tool with lower radius, for a tool with increased

radius, the infeed is in the opposite direction.

/LPLWLQJVXUIDFH

7RROZLWKVPDOOHUUDGLXV

IHHGWRWKHOLPLWLQJVXUIDFH

6WDQGDUGWRRO

0DFKLQLQJVXUIDFH

Contrary to all other tool offsets of G code group 22, tool parameter

$TC_DP6 specified for

CUT3DCCD does not influence the tool radius and the resulting compensation.

The compensation offset is the sum of:

● The wear value of the tool radius (tool parameter

$TC_DP15)

● and a tool offset

OFFN programmed to calculate the perpendicular offset to the limitation

surface.

The generated part program does not specify whether the surface to be machined is to the

right or left of the path. It is therefore assumed that the radius is a positive value and the

wear value of the original tool is a negative value. A negative wear value always describes a

tool with a lower diameter.

Using cylindrical tools

When cylindrical tools are used, infeed is only necessary if the machining surface and the

surface of limitation form an acute angle (less than 90 degrees). If a torus milling tool

(cylinder with rounded corners) is used, tool infeed in the longitudinal direction is required for

both acute and obtuse angles.

Loading...

Loading...