Tool offsets

7.11 Cutting data modification for tools that can be rotated (CUTMOD)

Job planning

448 Programming Manual, 07/2010, 6FC5398-2BP40-0BA0

Explanations:

In block

N180, initially the tool is selected for CUTMOD=0 and non-rotated toolholders that can be

orientated. As all offset vectors of the toolholder that can be orientated are 0, the position

that corresponds to the tool lengths specified in

$TC_DP3[1,1] and $TC_DP4[1,1] is

approached.

The toolholder that can be orientated with a rotation of 30° around the B axis is activated in

block

N200. As the tool nose position is not modified due to CUTMOD=0, the old tool nose

reference point is decisive just as before. This is the reason that in block

N210 the position is

approached, which keeps the old tool nose reference point at the zero (i.e. the vector (1, 12)

is rotated through 30° in the Z/X plane).

In block

N260, contrary to block N200 CUTMOD=2 is effective. As a result of the rotation of the

toolholder that can be orientated, the modified tool nose position becomes 8. The

consequence of this is also the different axis positions.

The tool radius compensation (TRC) is activated in blocks

N220 and/or N270. The different

tool nose positions in both program sections has no effect on the end positions of the blocks

in which the TRC is active; the corresponding positions are therefore identical. The different

tool nose positions only become effective again in the deselect blocks

N260 and/or N300.

Further information

Effectiveness of the modified cutting data

The modified tool nose position and the modified tool nose reference point are immediately

effective when programming, even for a tool that is already active. A tool does not have to be

re-selected for this purpose.

Influence of the active machining plane

To determine modified tool nose position, cutting direction and holder or clearance angle, the

evaluation of the cutting edge in the active plane (

G17 - G19) is decisive.

However, if setting data SD42940 $SC_TOOL_LENGTH_CONST (change of the tool length

component when selecting the plane), a valid value not equal to zero (plus or minus 17, 18

or 19), then its contents define the plane in which the relevant quantities are evaluated.

System variables

The following system variables are available:

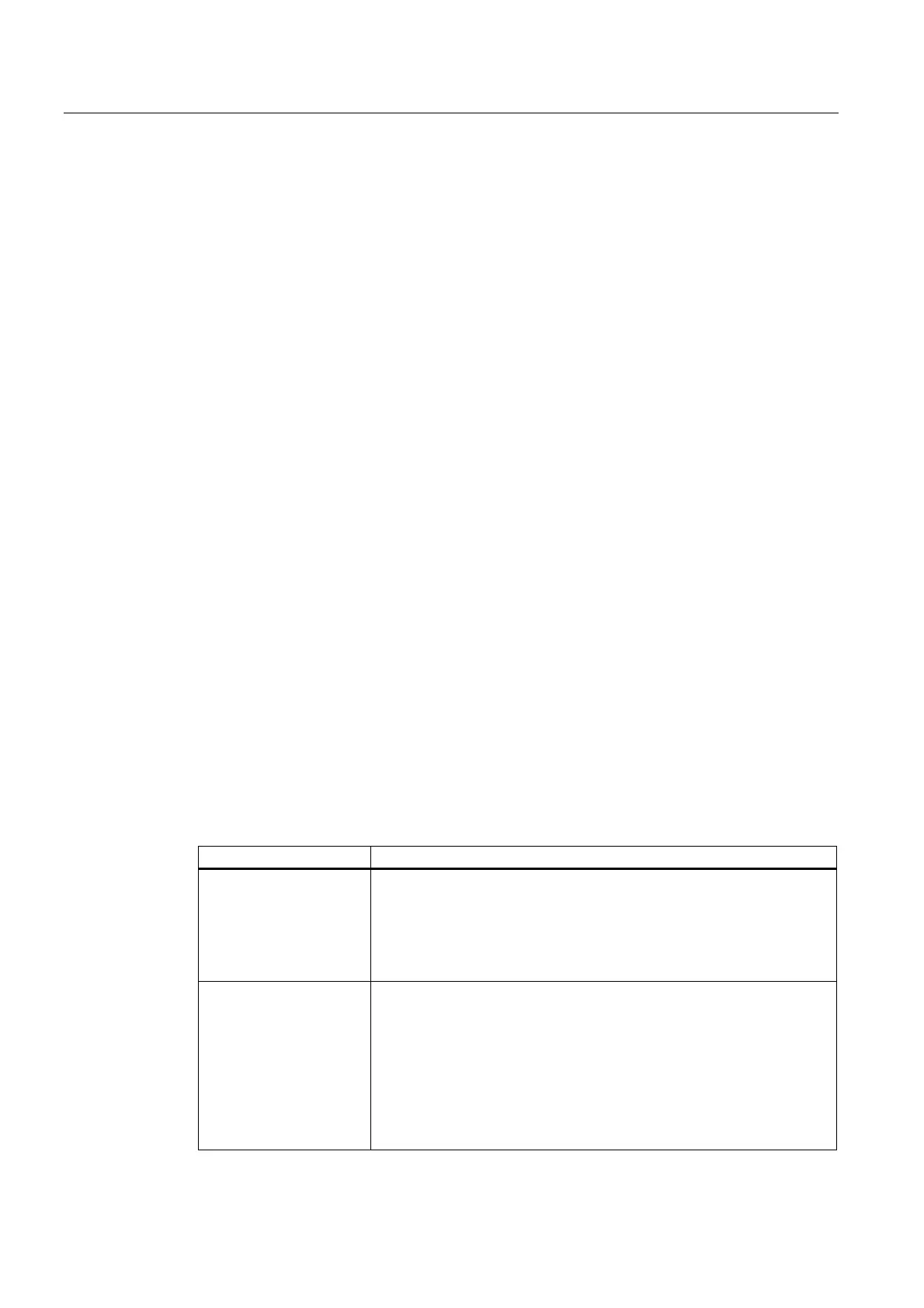

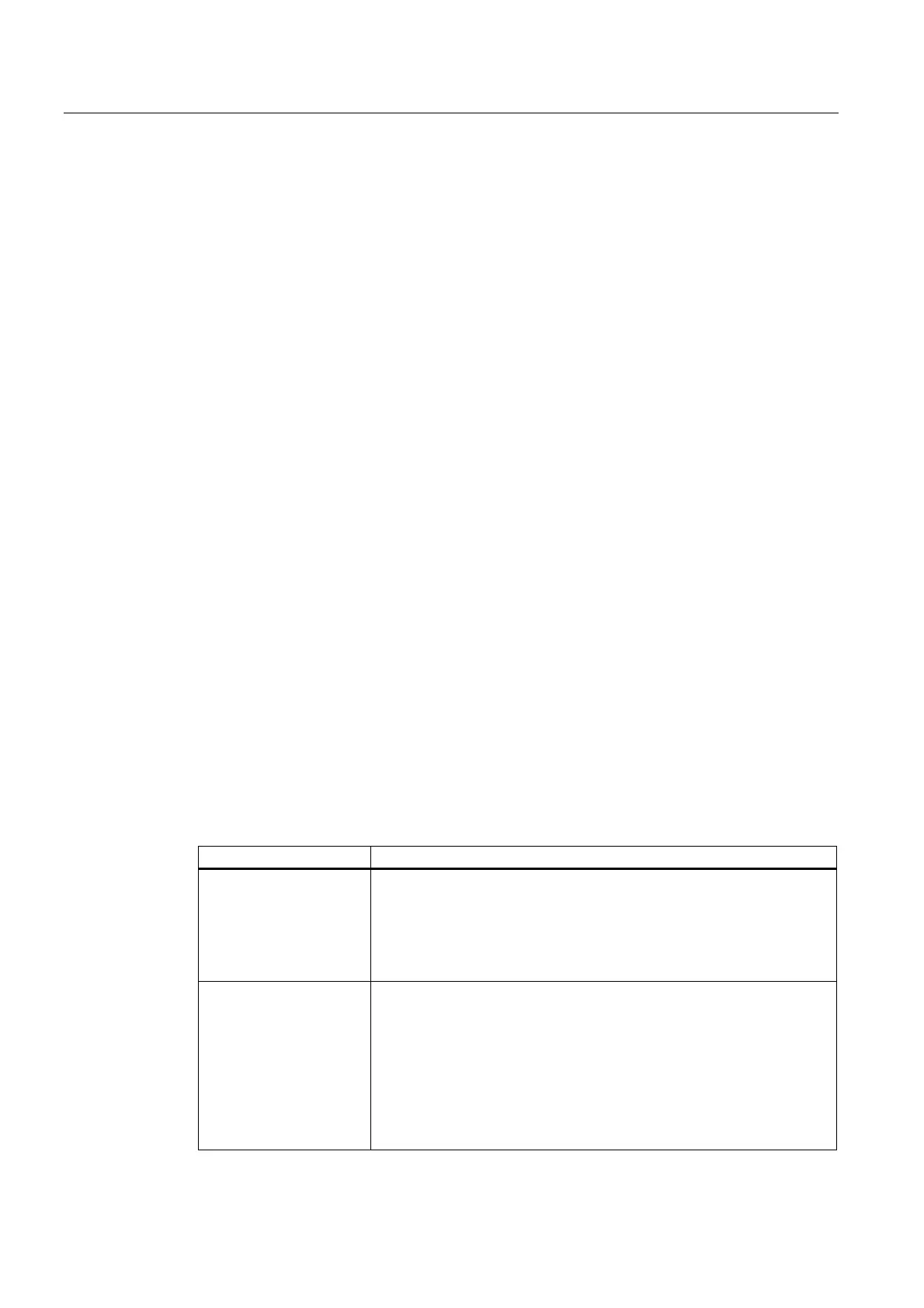

System variables Significance

$P_CUTMOD_ANG /

$AC_CUTMOD_ANG

Supplies the (non-rounded) angle in the active machining plane, that was

used as basis for the modification of the cutting data (tool nose position,

cut direction, clearance angle and holder angle) for the functions

activated using

CUTMOD and/or $SC_CUTDIRMOD.

$P_CUTMOD_ANG refers to the actual state in the preprocessing,

$AC_CUTMOD_ANG to the actual main run block.

$P_CUTMOD /

$AC_CUTMOD

Reads the currently valid value that was last programmed using the

command CUTMOD (number of the toolholder that should be activated for

the cutting data modification).

If the last programmed CUTMOD value = -2 (activation with the currently

active toolholder that can be orientated), then the value -2 is not returned

in $P_CUTMOD, but the number of the active toolholder that can be

orientated at the time of programming.

$P_CUTMOD refers to the actual state in the preprocessing,

$AC_CUTMOD to the actual main run block.

Loading...

Loading...