10

1.7 Referenced documents

In addition to this manual, the following documents must

be observed by the respective target group:

• Company instructions and approval rules

If applicable:

• Safety data sheet of the lubricant used

• Project planning documents

• Supplementary information regarding special designs

of the pump. This you will find in the special system

documentation.

• Instructions for other components for setting up the

centralized lubrication system.

1.8 Prohibition of certain activities

• Replacement of or modifications to the pistons of the

pump elements

• Repairs or modifications to the drive.

• Alterations to the control circuit board beyond

adjustment of lubrication times and interval times or

replacement in case of defect.

1.9 Painting plastic components and

seals

The painting of any plastic components and seals of the

products described is prohibited. Completely mask or

remove plastic components before painting the main

machine.

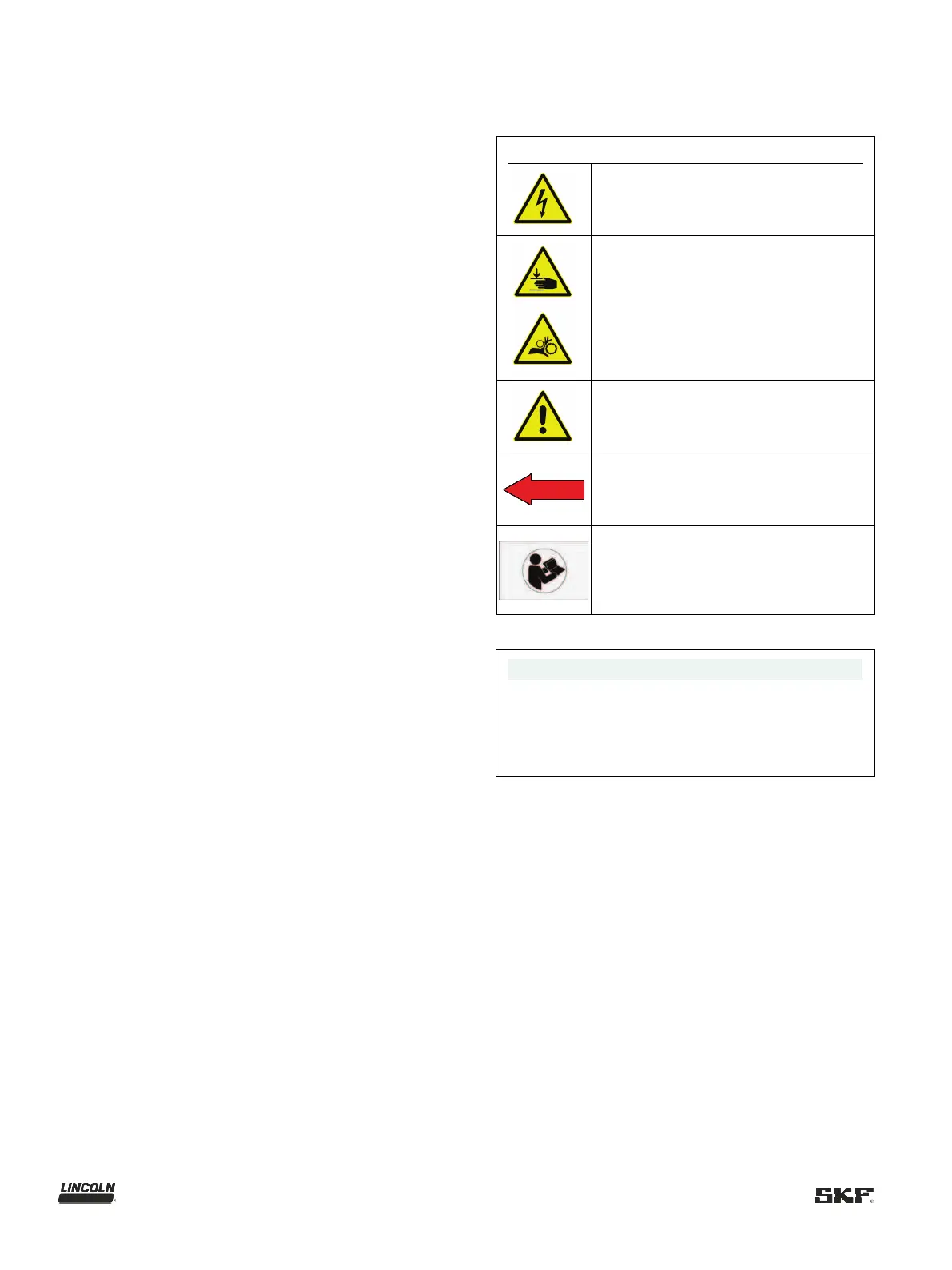

1.10 Safety markings on the product

Risk of dangerous electrical voltage

(for VAC pumps only)

Risk of wrapping, pinching, crushing, or

shearing when the reservoir lid is open

(only for reservoirs with filling from above)

Risk of injury from spring tension

(only for pumps with a follower plate)

Direction of rotation of the pump (stirring

paddle)

Read the instructions

(before initial filling of a pump with

double-

lip follower plate delivered without

lubricant)

Possible safety markings on the product

Further to the findings of the workplace risk

evaluation the operating company has to attach

additional markings (e. g. warnings, signs giving

orders, prohibition signs or labelling as specified by

CLP / GHS), where appropriate.

Loading...

Loading...