48

6.7 Connection of the lubrication line

CAUTION

Risk of slipping

Exercise caution when

handling lubricants.

Immediately remove and bind any leaked

lubricants.

NOTICE

Damage to the higher-level machine caused by

faulty planning of the centralized lubrication system

All parts for the construction of the centralized

lubrication system must be designed for the

maximum operating pressure that occurs, the

permissible ambient temperature range, the required

delivery volume, and the lubricant to be supplied.

Observe the following assembly information for safe and

trouble-free operation:

• Generally valid regulations and company regulations

regarding the laying of pressurized pipe and hose lines

must be observed.

• Use only clean, pre-filled components and lubrication

piping.

• Secure every lubricant line on the pump against

excessive pressure through the use of a suitable

pressure limiting valve (only in the case of pumps

without an internal pressure limiting valve).

• The main lubricant line should be routed on a rising

gradient and should be able to be bled at the highest

point. Lubrication lines should always be arranged so

that air inclusions cannot form anywhere.

• Install lubricant metering devices at the end of the

main lubricant line such that the outlets of the

lubricant metering devices point upwards wherever

possible.

• If the system configuration requires that the lubricant

metering devices be arranged below the main lubricant

line, they should not be placed at the end of the main

lubricant line.

• The flow of lubricant should not be impeded by the

presence of sharp bends, angle valves, flap valves,

seals protruding inward, or changes in cross-section

(large to small). Unavoidable changes in the cross-

section in lubrication lines must have smooth

transitions.

• Connect the lubricant lines in such a way that no

mechanical forces are transferred to the product

(stress-free connection).

• Lubrication piping is to be positioned in such a way

that they cannot become kinked, pinched or frayed.

6.8 Filling with lubricant

6.8.1 Filling via the reservoir cover

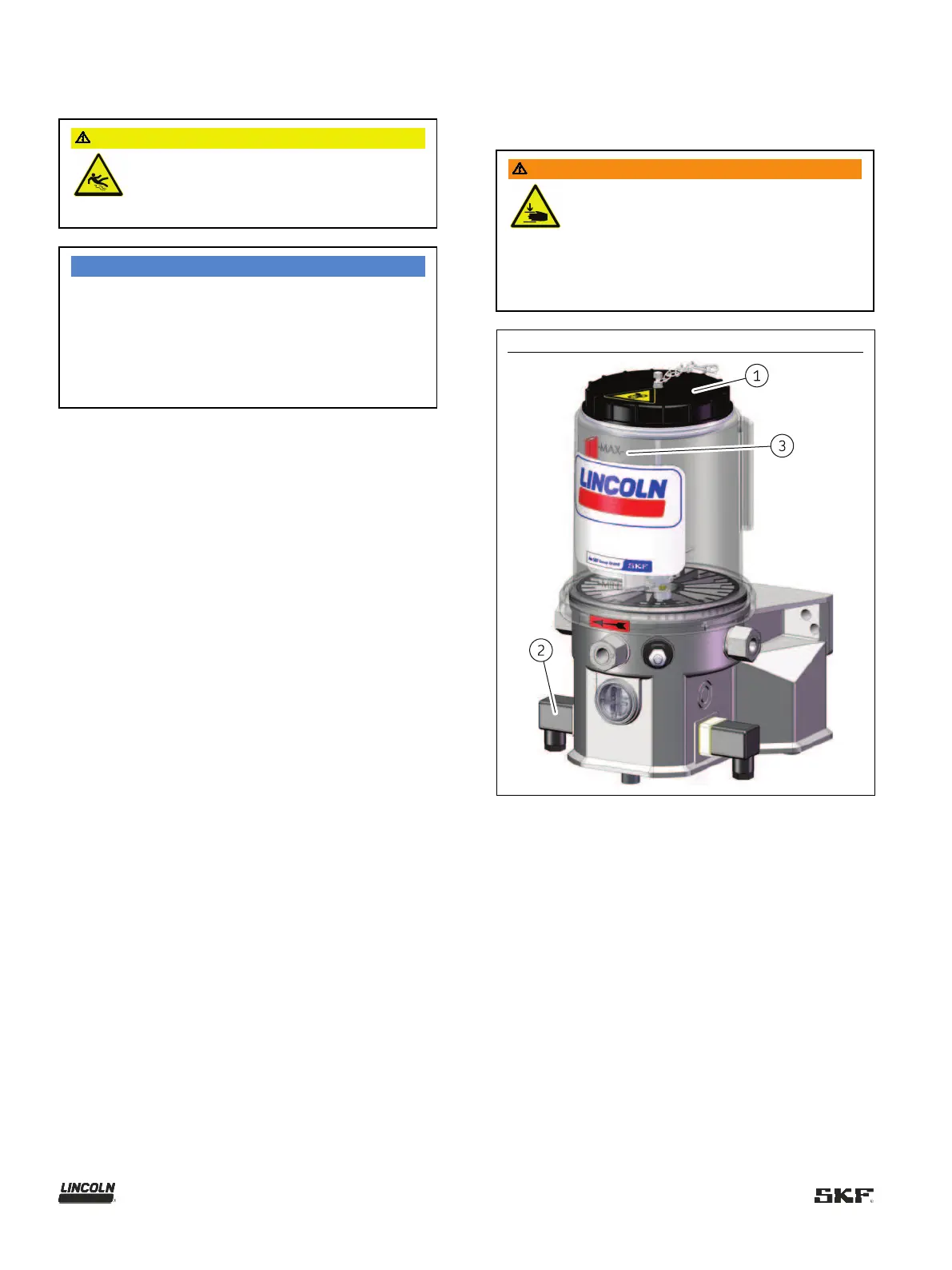

WARNING

Crushing hazard

Crushing hazard on the rotating stirring

paddle. Filling through the opening of the

reservoir lid is permitted only when the pump

has been disconnected

electrically

beforehand by detaching the connection

(Fig.

27/ 2) from the power supply.

Fig.

Filling via the reservoir cover

1. the power supply to the pump by detaching the

connector (Fig. 27/2).

2. Turn the reservoir lid (Fig. 27/1) counterclockwise and

detach it from the reservoir. Set the reservoir cover

down at a clean location. The inner side of the reservoir

cover must not become contaminated. Remove any

contaminations which may be present.

3. Fill the reservoir from the top up to the "MAX" marking

(Fig. 27/3). Take care to ensure while doing so that the

lubricant is filled in without air inclusions if at all

possible.

4. Reinstall the reservoir cover (Fig. 27/1) in clockwise

direction.

5. Restore the power supply to the pump by attaching the

connector (Fig. 27/2) and screwing it firmly in place.

Loading...

Loading...