57

8 Operation

SKF products operate automatically to the greatest

possible extent.

Basically, activities during standard operation are limited

to:

• Regular function checks

• Checking the fill level on pumps without low-level

signal

• Timely refilling of lubricant

• Cleaning the exterior if dirty

8.1 Top up lubricant

See section Filling with lubricant, Page 48.

8.2 Triggering additional lubrication

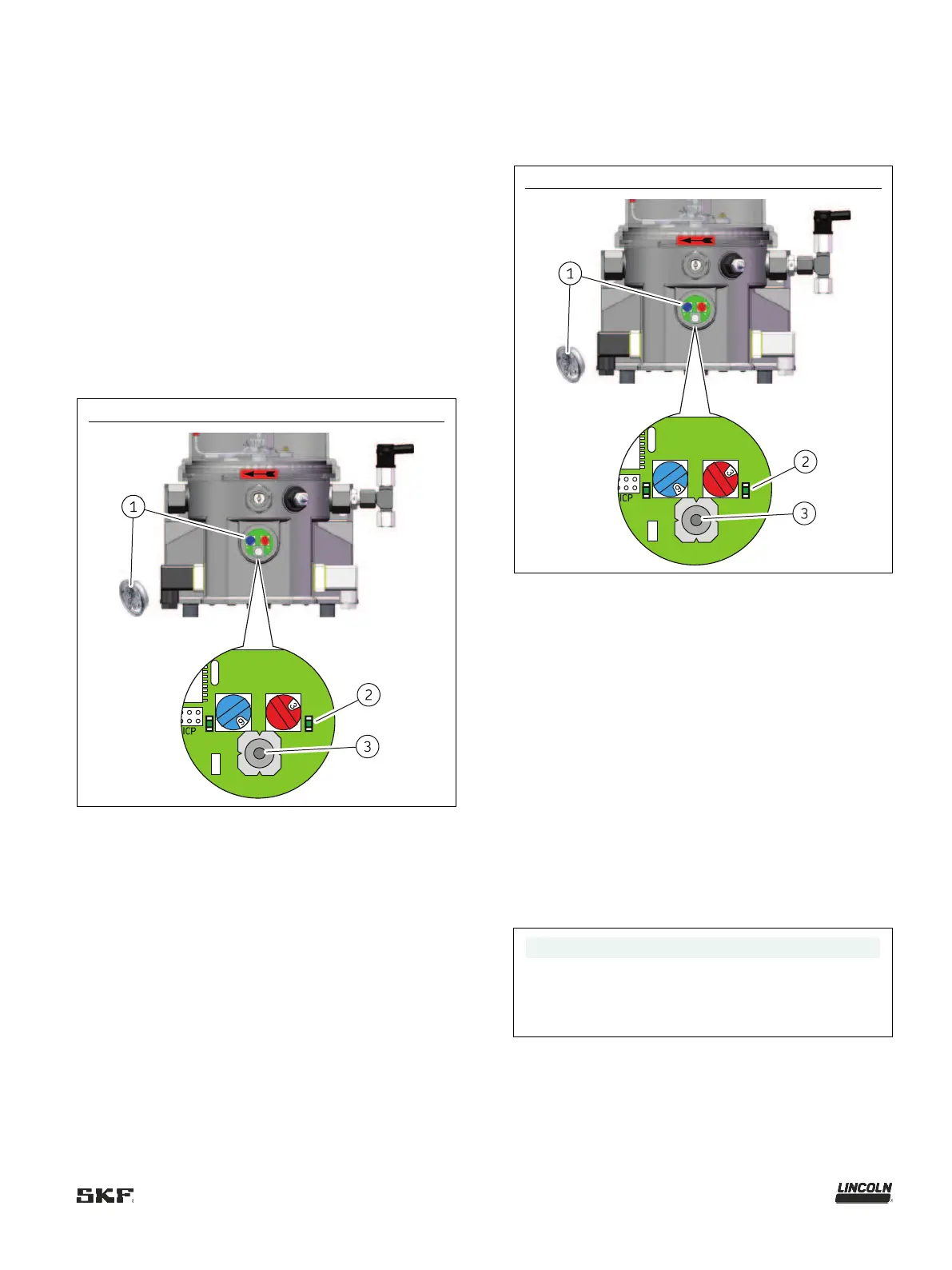

Fig.

Triggering additional lubrication

2 LED for “Operation / fault”

(steady light = pump is

To trigger additional lubrication, proceed as follows:

1. Remove the screw cap (Fig. 36/1) together with the

packing ring.

2. To trigger additional lubrication, press the

pushbutton (Fig. 36/3) on the control circuit board (for

more than 2 seconds). The right-hand LED (Fig. 36/2)

lights up for as long as the motor runs.

– The pump starts a lubrication cycle. The duration of

the lubrication cycle is determined by the value set

on the control circuit board.

3. Reinstall the screw cap and the packing ring.

– Tightening torque: 2 Nm ±0.2 Nm [1.48 ft.lb.

±0.15 ft.lb.]

8.3 Resetting an error message

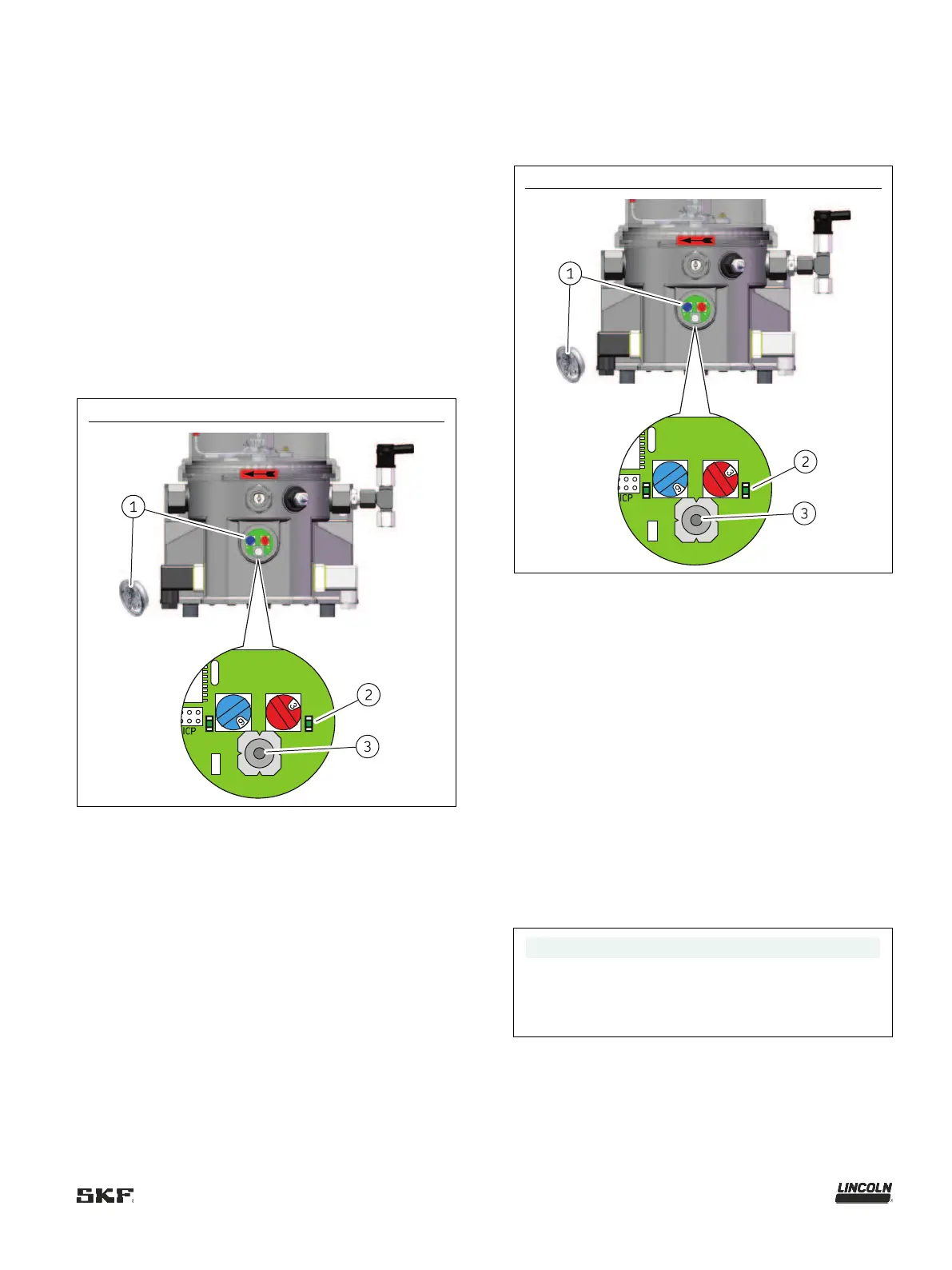

Fig.

Resetting an error message

LED for “Operation / fault”

To reset an error message, proceed as follows:

1. Based on the flashing frequency of the LED (Fig. 37/2),

localize and remedy the fault: see chapter 11.1.

2. Remove the screw cap (Fig. 37/1) together with the

packing ring.

3. To reset the error message, press the

pushbutton (Fig. 37/3) on the control circuit board (for

less than 1 second). The right-hand LED goes off.

4. To switch on the pump, press the pushbutton again (for

more than 2 seconds). An additional lubrication is

carried out.

5. Reinstall the screw cap and the packing ring.

– Tightening torque: 2 Nm ±0.2 Nm [1.48 ft.lb.

±0.15 ft.lb.]

NOTE

If a fault is not reset, it remains saved even when the

machine contact/driver switch is switched off,

meaning that when the pump is switched back on, the

right

-hand LED will flash to indicate the active fault.

Loading...

Loading...