22

4.4 Principle of operation of the

intermittent low-level signal

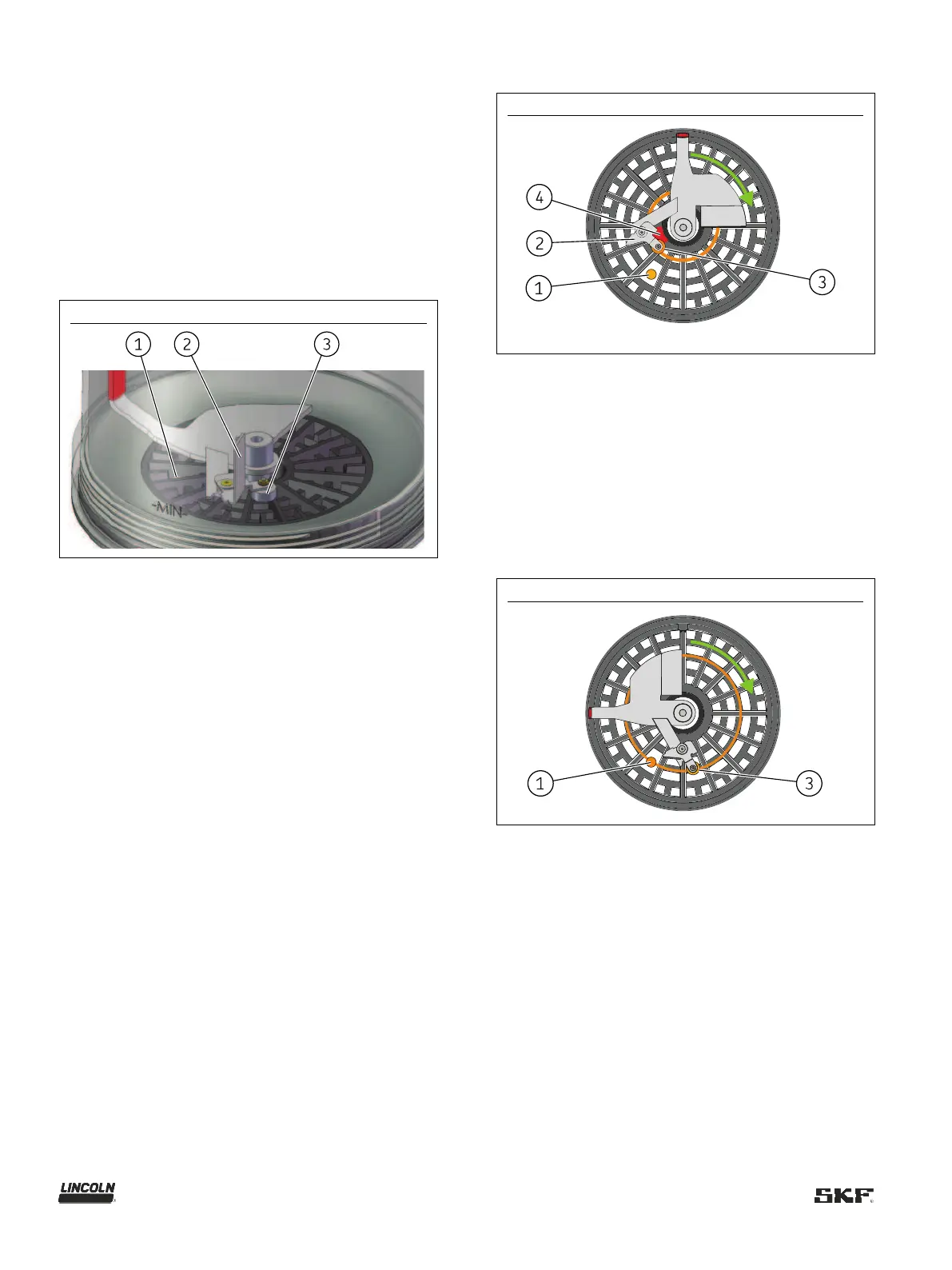

Components of the intermittent low-level signal

The intermittent low-level signal uses a contactless

mechanism, comprised essentially of the following parts:

• Stationary reed switch (Fig. 11 to 13/1) in the reservoir

bottom

• Mobile baffle plate (Fig. 11 to 12/2) connected to the

stirring paddle, with a magnet (Fig. 11 to 13/3) and a

cam (Fig. 12/4)

Fig.

Perspective view

Functional description of the intermittent low-level

signal

1 When the reservoir is filled with a lubrication grease

that is suitable for the intermittent low-level signal, and

the pump is running, the baffle plate (Fig. 11 to 12/2) is

deflected outwards by the resistance of the lubrication

grease.

2 As a result, the magnet (Fig. 11 to 13/3) connected to

the baffle plate moves along its inner circular path

(Fig. 12), which means that it cannot trigger a pulse on

the reed switch (Fig. 11 to 13/1).

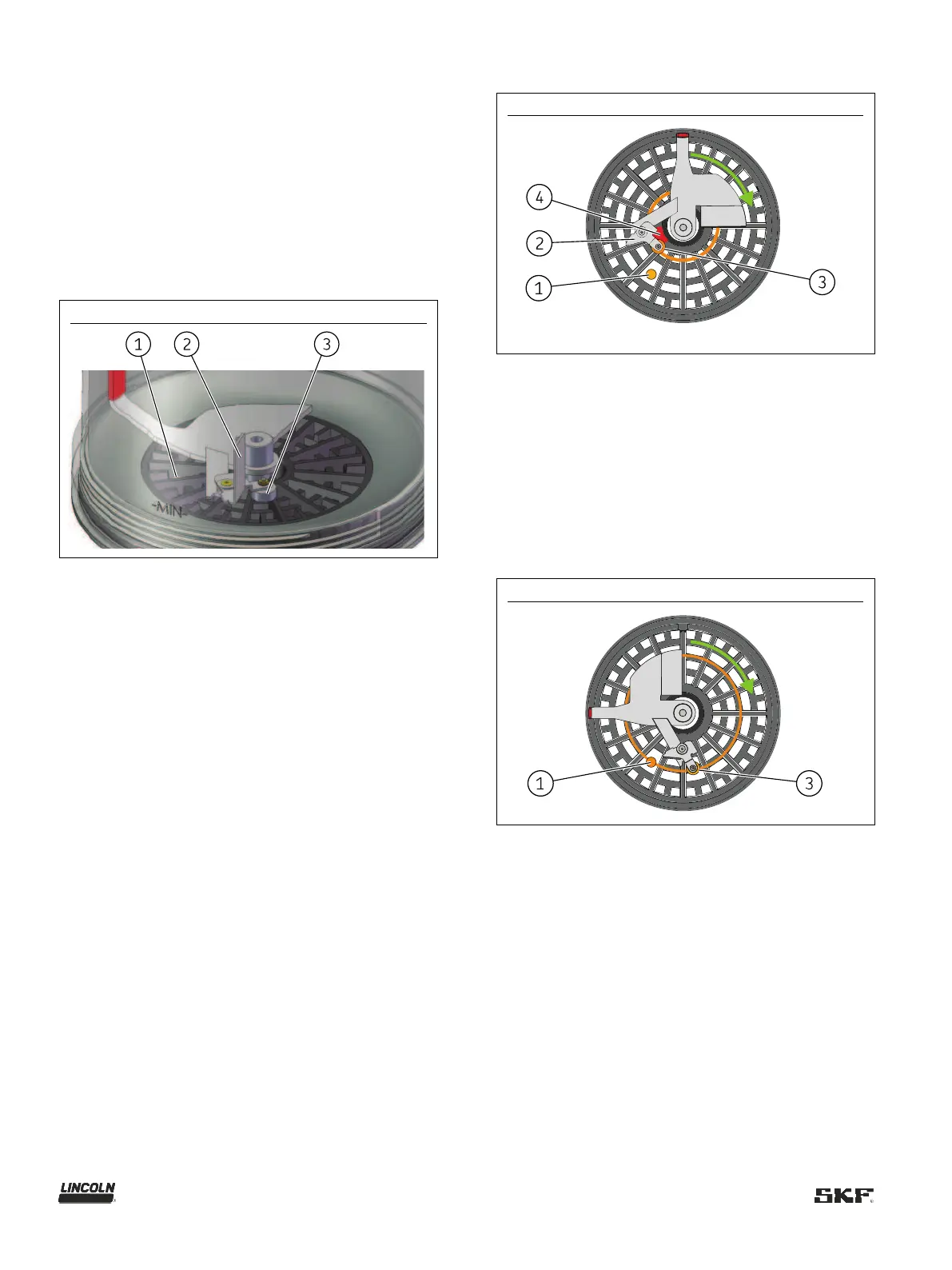

3 During each revolution, a cam (Fig. 12/4) forces the

magnet and the pivot-mounted baffle plate back out

onto the outer circular path (Fig. 13)

4 After passing the cam, the resistance of the lubricant

pushes the baffle plate and the magnet back inwards,

onto the inner circular path.

Fig.

Magnet on inner circular path

5 When the lubricant level in the reservoir drops so far

that the resistance of the lubrication grease is no

longer enough to deflect the baffle plate

(Fig. 11 to 12/2), the magnet (Fig. 11 to 13/3) stays on

the outer path, triggering a pulse during each revolution

as it slides over the reed switch (Fig. 11 to 13/1).

6 If the magnet (Fig. 11 to 13/3) moves over the reed

switch (Fig. 11 to 13/1) on the outer circular path six

times during one work cycle, a low-level signal is output

directly on the pump's signal connection.

Fig.

Magnet on outer circular path

Loading...

Loading...