-54-

No.EX※※-OMS0027

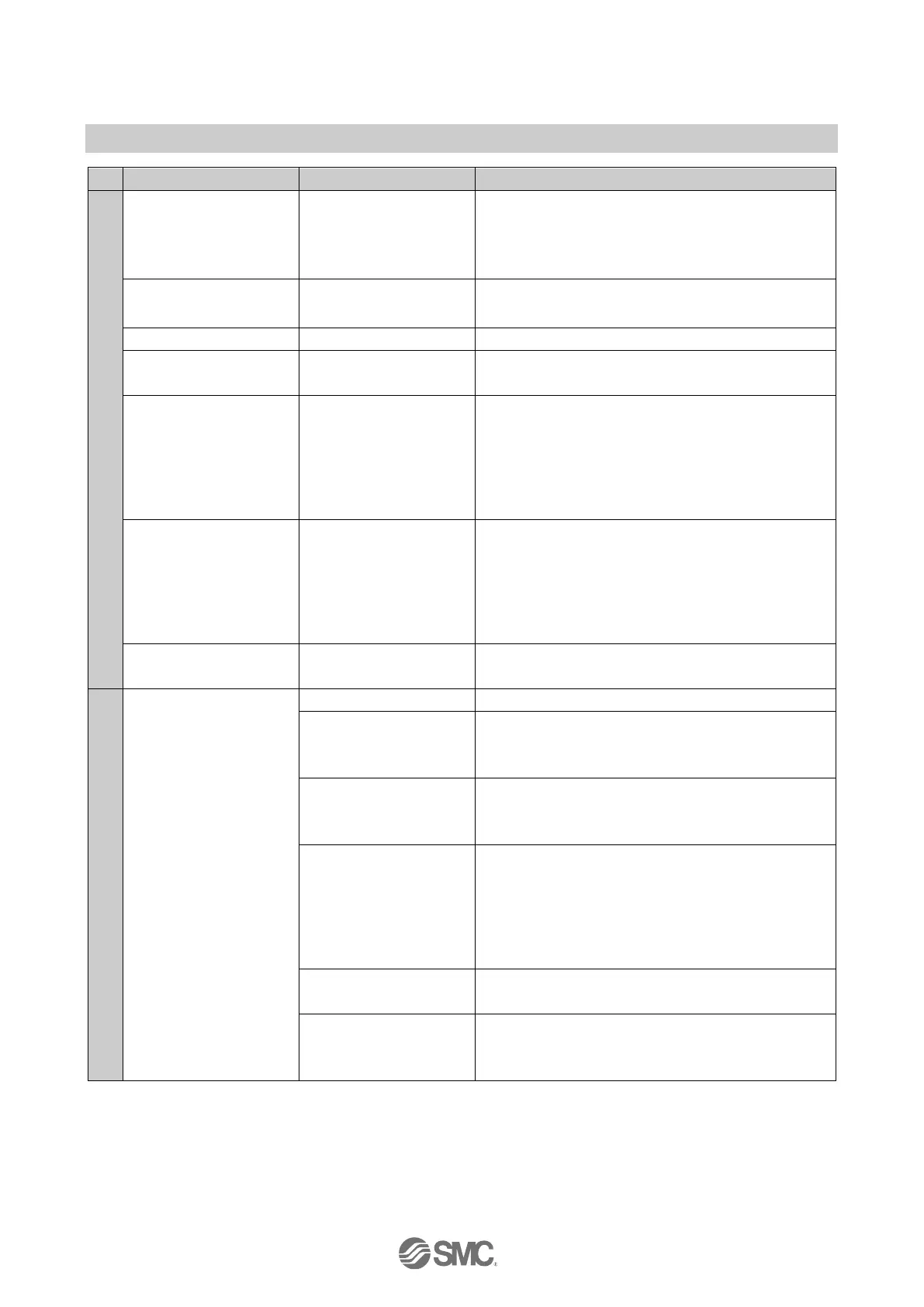

•Analogue I/O unit parameters (1)

No. Parameter Definition Item Content

Default

setting

Parameter

setting range

Enable Generates an error.

○

1

The power

supply short

circuit

detection for

the input or

output device

Generates error

when the short

circuit of the input

device power

supply or output

device is detected.

Disable

Does not generate an

error.

Unit

0..10 V

0..5 V

1..5 V

0..20 mA

2

Analogue

input or

output range

Sets the analogue

input or output

range.

4..20 mA

Select the analogue input

or output range.

1..5 V

Channel

Offset binary Offset binary.

○

Sign &

Magnitude

Signed binary.

2s complement 2’s complement.

3

Analogue

data format

Sets analogue data

type which is

output to PLC.

Scaled Scale conversion type.

Unit

None None

2AVG 2 value average

○

4AVG 4 value average

4

Analogue

average filter

Sets analogue

input filtering time.

8AVG 8 value average

Channel

Enable Generates an error.

5

Over range

detection

Generates error

when the input

value exceeds

0.5% of full span.

Disable

Does not generate an

error.

○

Unit

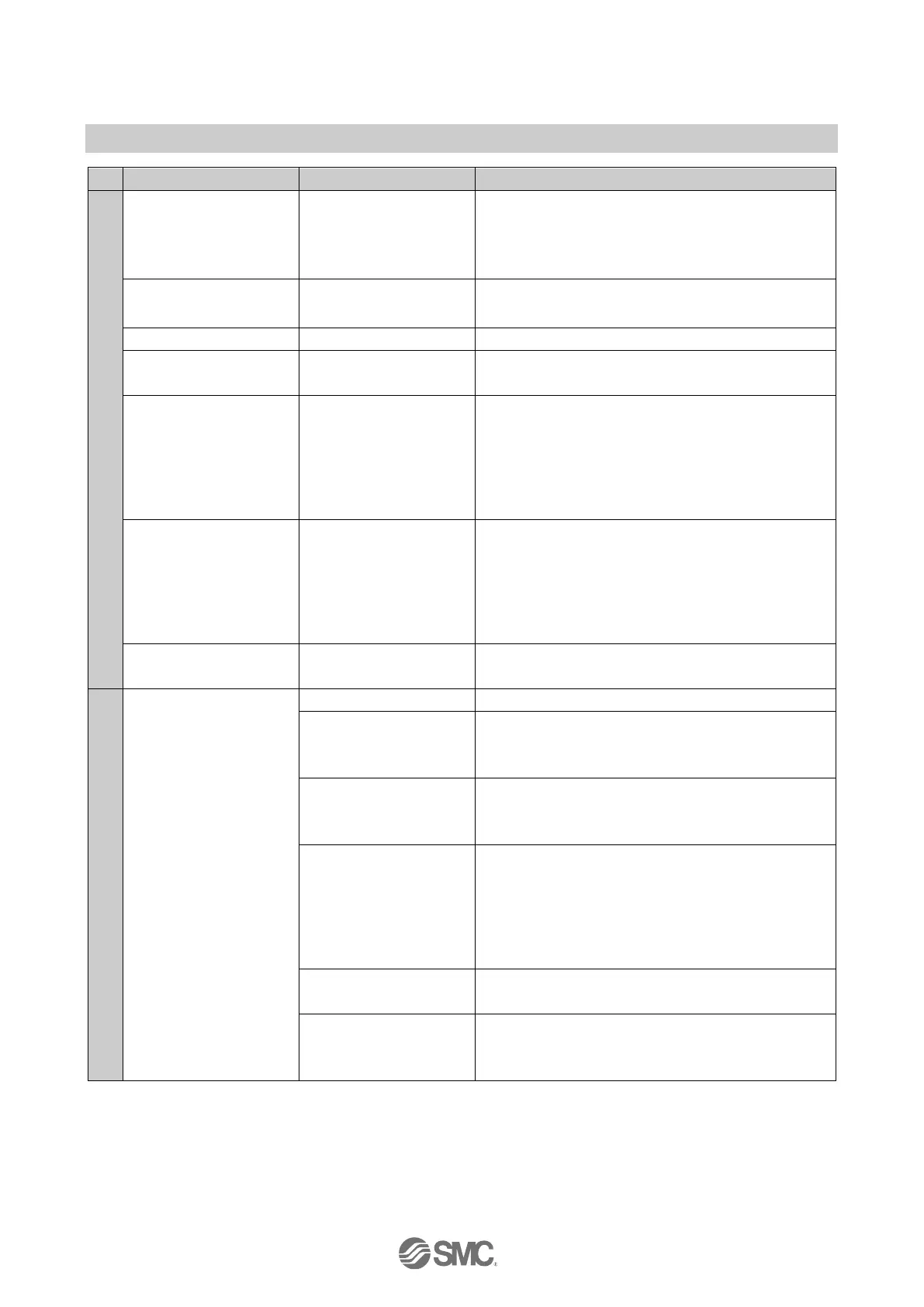

Enable Generates an error.

6

Under range

detection

Generates error

when the input

value falls below

0.5% of full span.

Disable

Does not generate an

error.

○

Unit

Enable Generates an error.

1

User’s set

value upper

limit error

Generates error

when the input or

output value

exceeds the set

value.

Disable

Does not generate an

error.

○

Enable

Generates an error.

Val: -32766 to 32767

7

Scale upper

limit setting

Sets the scale

upper limit.

Generates error

when the input or

output value

exceeds the upper

limit.

Disable

Does not generated an

error.

Val: -32766 to 32767

○

Val: 1000

Channel

Loading...

Loading...