Welding operation

74 Operating Instructions Soyer Bolzenschweißtechnik

14.2 Notes on checking the quality of the weld

If the SOYER® stud welding equipment is handled correctly and the correct

materials are selected, the strength of the welding joint (welding zone) is always

higher than the strength of the stud or the base material.

In practice, the following production control tests have proved successful:

• Visual inspection

• Bend test

For further information, see standard:

DIN EN ISO 14555 Arc stud welding of metallic materials or Technical Bulletin

DVS 0904 Instruction for practice - Arc stud welding.

14.2.1 Visual inspection

The visual inspection serves as a rough check for major defects. The uniformity

of the weld is assessed.

The following table serves as an aid for the assessment of the welding result:

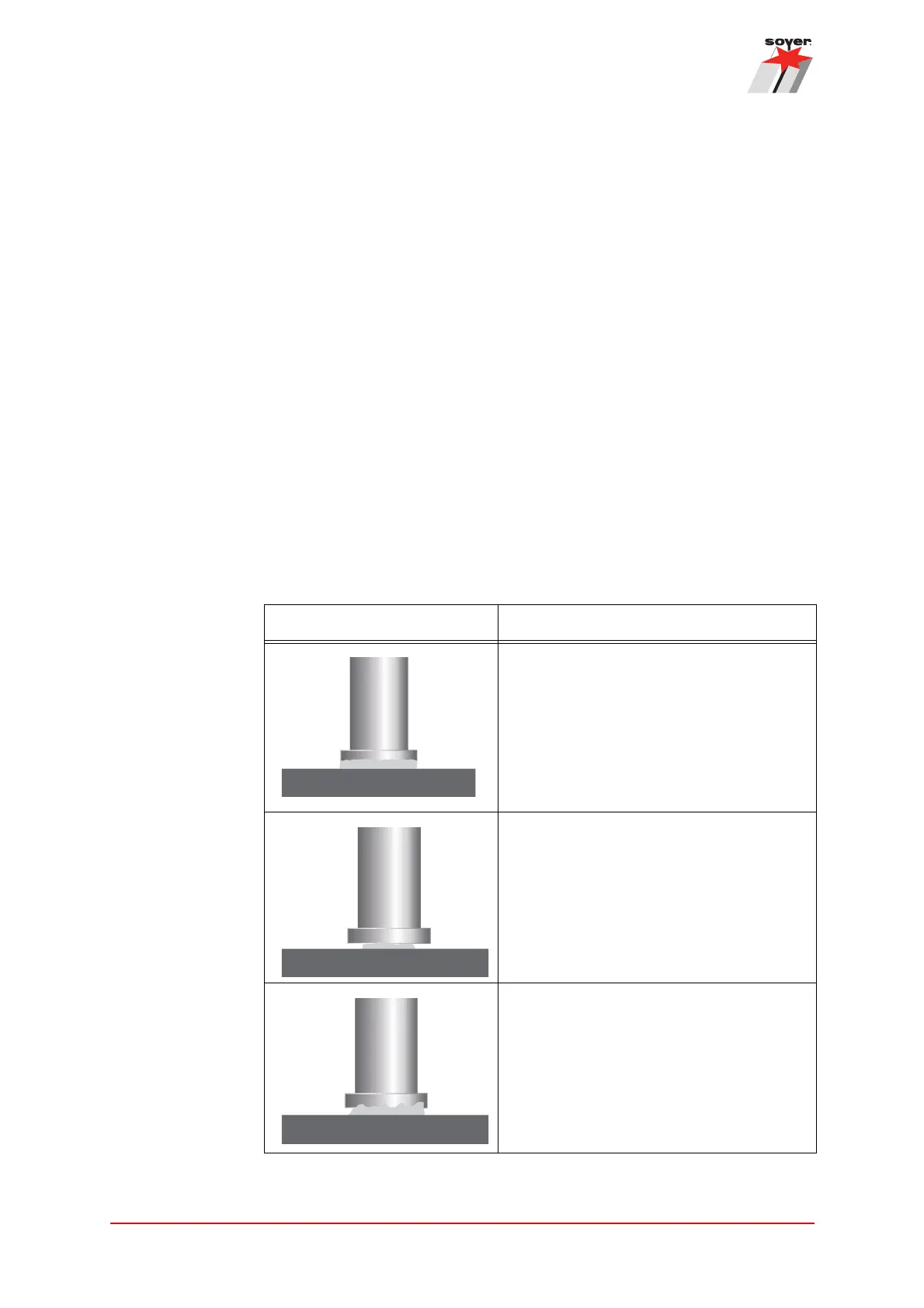

Visual inspection

Welding image Note

Good welding joint.

Optimum setting.

Even, bright and closed small welding

bead.

Poor welding joint, e.g. because the

welding energy is too high or the

immersion distance / lift is too small.

The stud is constricted to the welding

joint. The stud is only partially welded.

Poor welding joint, e.g. because the

welding energy is too low or the lift is

too short.

The welding bead is weak and unevenly

formed.

Loading...

Loading...