88 TS 700, TS 800

A damaged impulse hose may lead

to impaired engine performance.

– Remove shroud, b 7.4

– Remove air guide shroud,

b 7.5

– Unscrew the rubber buffers on

the ignition and clutch sides,

b 10.2

– Unscrew the rubber buffers for

the front handle,

b 10.1

– Remove the carburetor,

b 12.2.1

– Troubleshooting, b 4.4 or

b 4.5

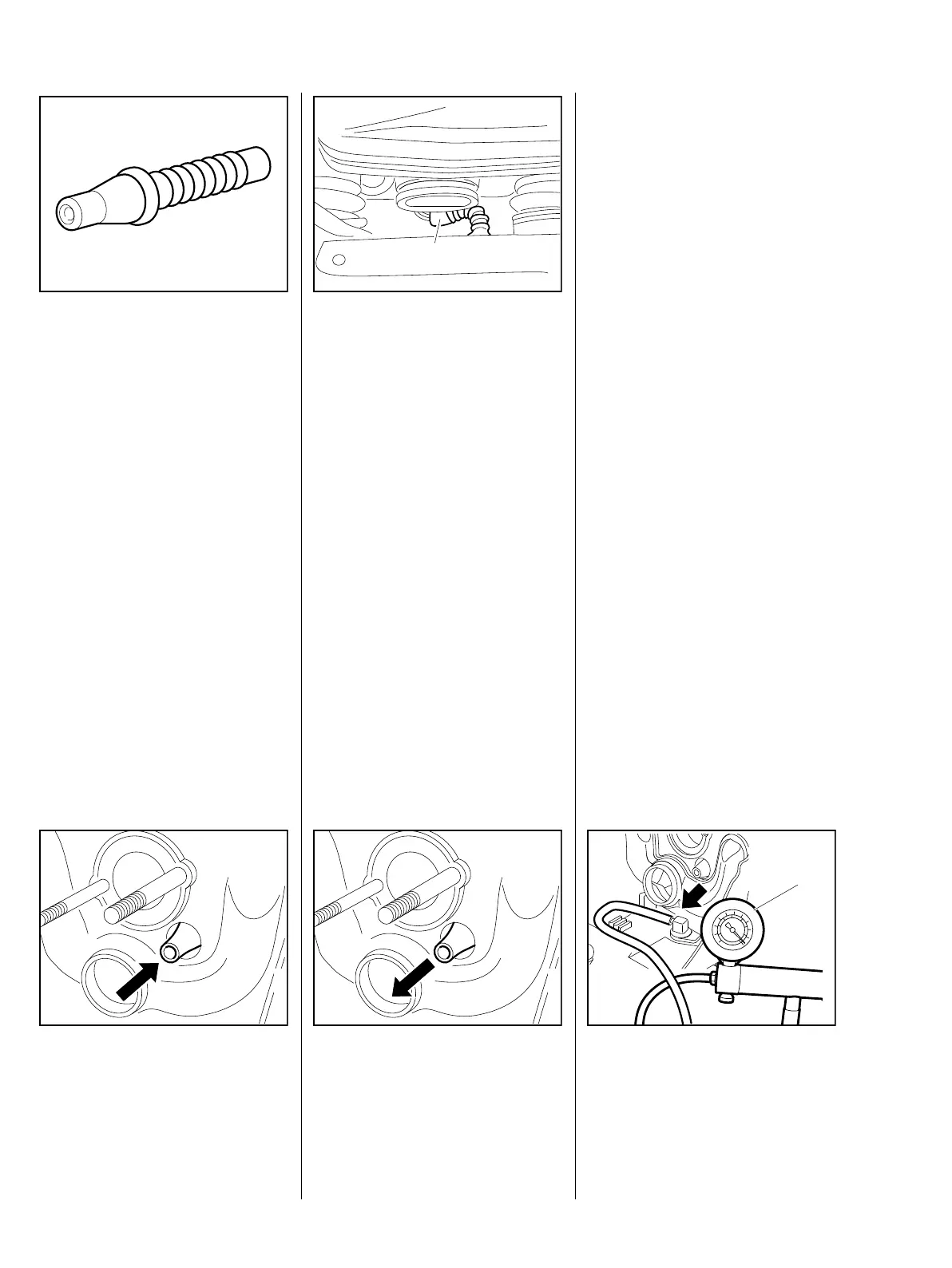

: Press the impulse hose out of the

hole in the tank housing, towards

the cylinder.

: Disconnect the impulse hose (1)

from the cylinder.

The impulse hose is shown without

intake manifold for clarity.

– Reassemble parts in reverse

order.

1

Note:

Ensure that the impulse hose is

routed correctly and without kinking.

– Coat with Press Fluid OH 723,

b 14

Note:

Draw the impulse hose into the hole

in the tank housing until the

circumferential groove on the

impulse hose engages the tapered

end of the hole.

: Draw the impulse hose through

the hole in the tank housing.

– Reassemble remaining parts in

reverse order.

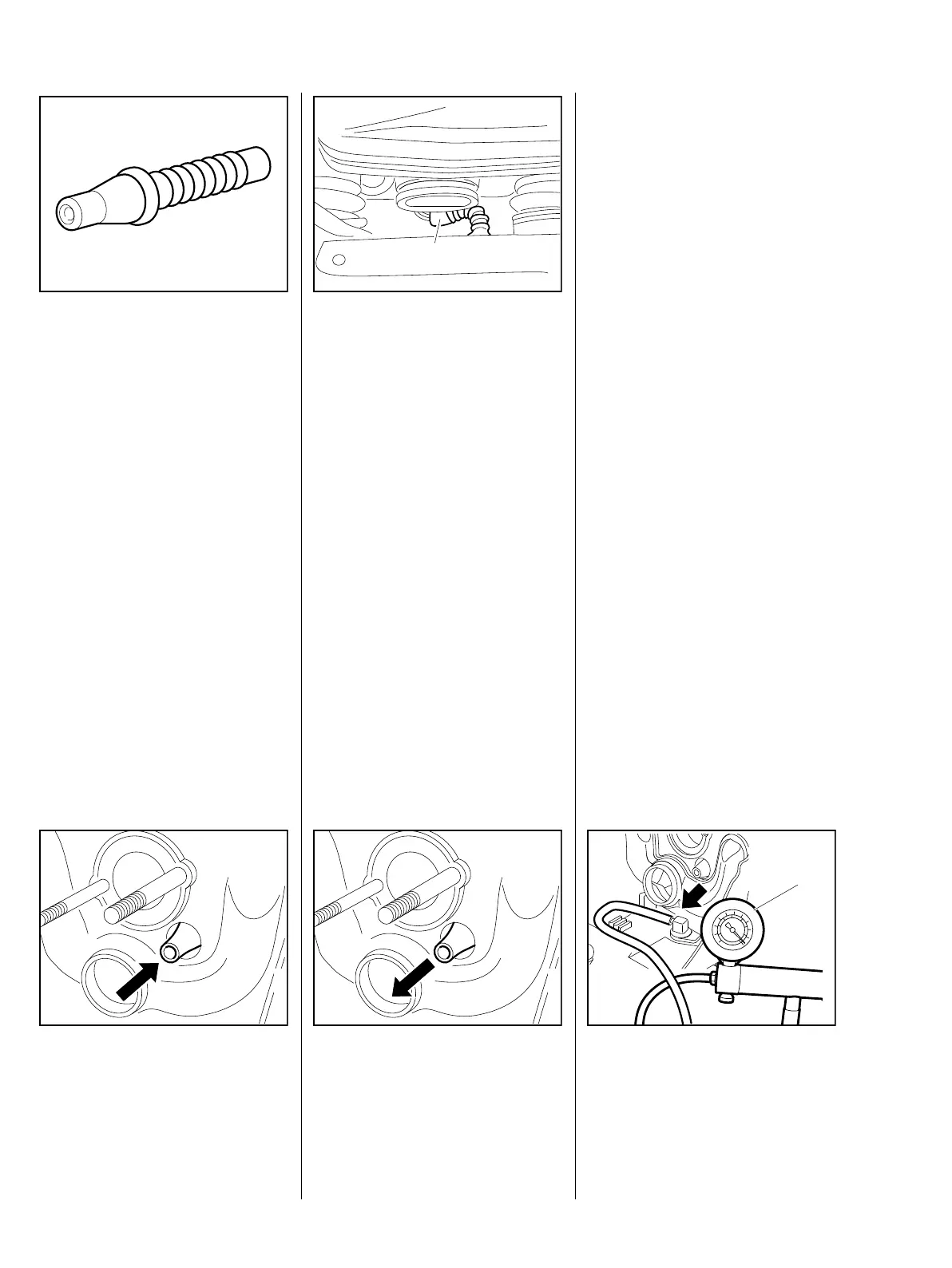

A pressure equilibrium must always

prevail between the inside of the

fuel tank and the surrounding

atmosphere to permit troublefree

operation of the carburetor. This is

ensured by the tank vent.

If problems develop in the

carburetor or fuel supply, the tank

vent must always also be tested and

replaced if necessary. Correct

functioning is determined by testing

the fuel tank with negative pressure

via the fuel hose.

– Remove the carburetor,

b 12.2.1

– Drain the fuel tank.

Note:

Ensure that the fuel is disposed of

correctly and without harming the

environment.

: Connect the vacuum pump (1)

0000 850 3501 to the elbow

connector (arrow) and apply a

negative pressure to the fuel

tank.

1

12.5.3 Impulse hose 12.6 Tank vent

12.6.1 Testing

Loading...

Loading...