Operation 4

Emergency operation

Adjustable fork arms

The standard design features f

orged fork arms

that are manually adjustable.

Pallets with

different dimensions can ther

efore be picked

up.

As an option, this industrial truck can also be

equipped with hydraulically adjustable fork

arms. The distance between the fork arms

must be sufficient so that the load cannot fall

and that there is support centrally below the

load centre of gravity. Adjust the fork arms

accordingly and lock in position.

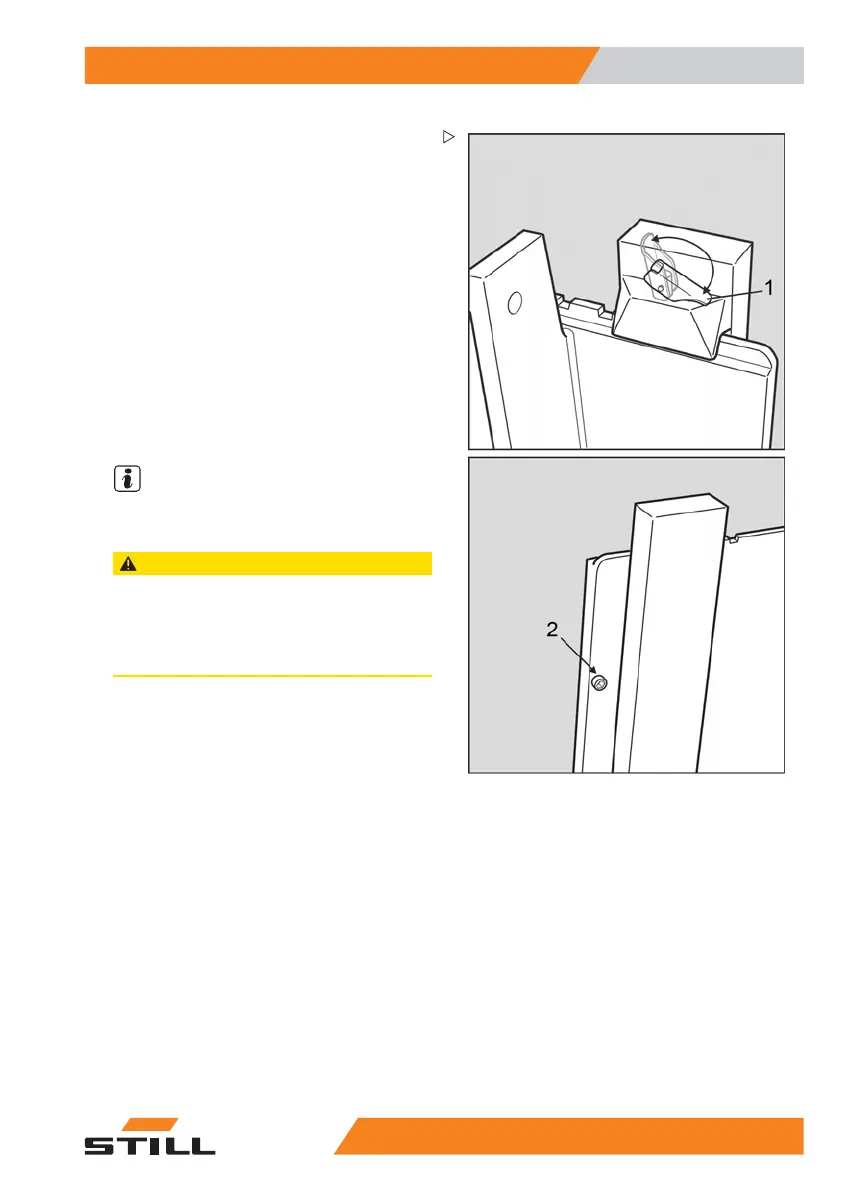

– To do this, lift the locking lever, move the

fork arms to the desired position and allow

the locking lever to engage again (1).

NOTE

If the locking lever is engaged, it is no longer

possible to move the fork arms laterally.

CAUTION

Risk of accident

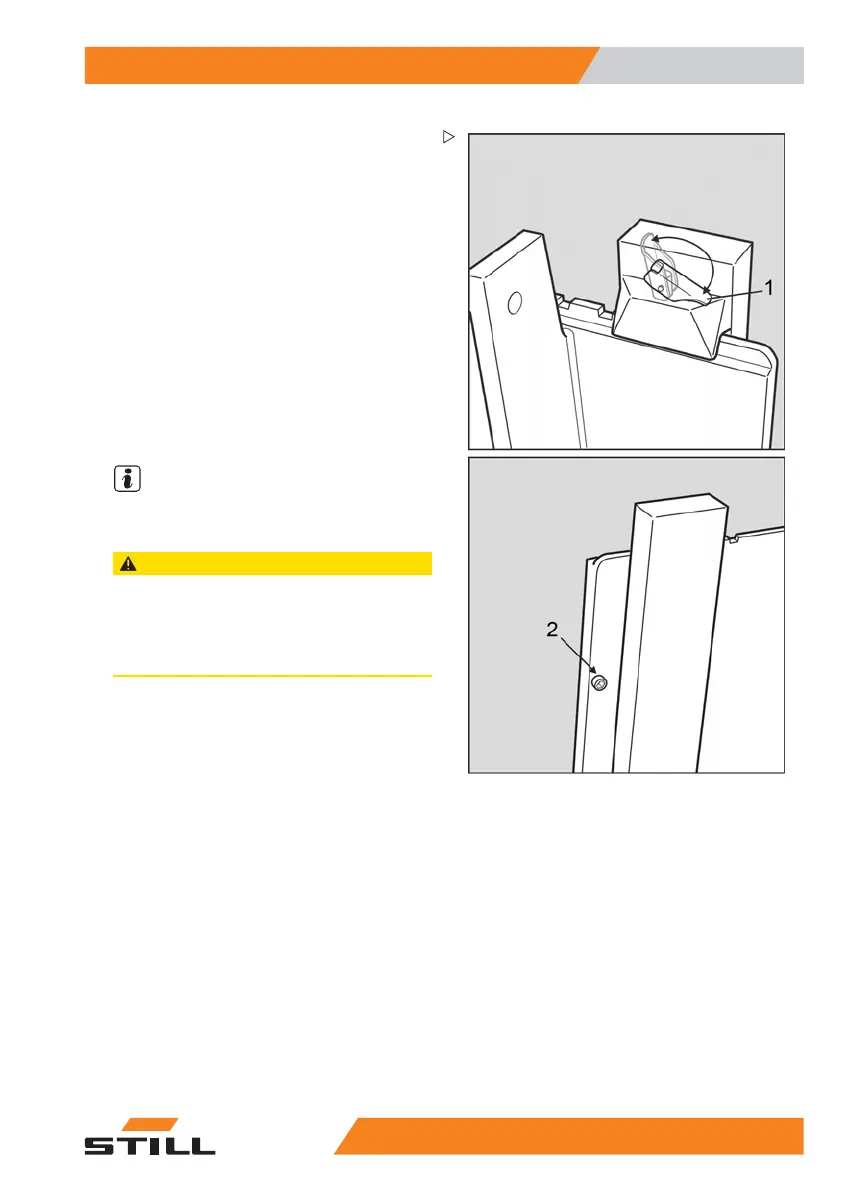

Thesideforkarmloc

king device (2) must be pre-

sent and must be in pe

rfect working order. Other-

wisetheforkarmsca

n be pushed out of the carrier

by lateral forces an

dfall.

*Option

Emergency operation

Emergency lowering

Emergency lowering function for the driver's

cab

If a technical defect causes the industrial truck

to shut down when the driver's cab is raised,

or if an operator in the raised cab becomes

incapable of operating the industrial truck (e.g.

falls unconscious), the driver's cab can be

lowered by a second person on the ground

using the hand-operated emergency lowering

valve.

523

1 804 2502 EN - 11/2017 71

Loading...

Loading...