RUN XT: Service & Maintenance Manual - rev. 2.0

Page 6.21

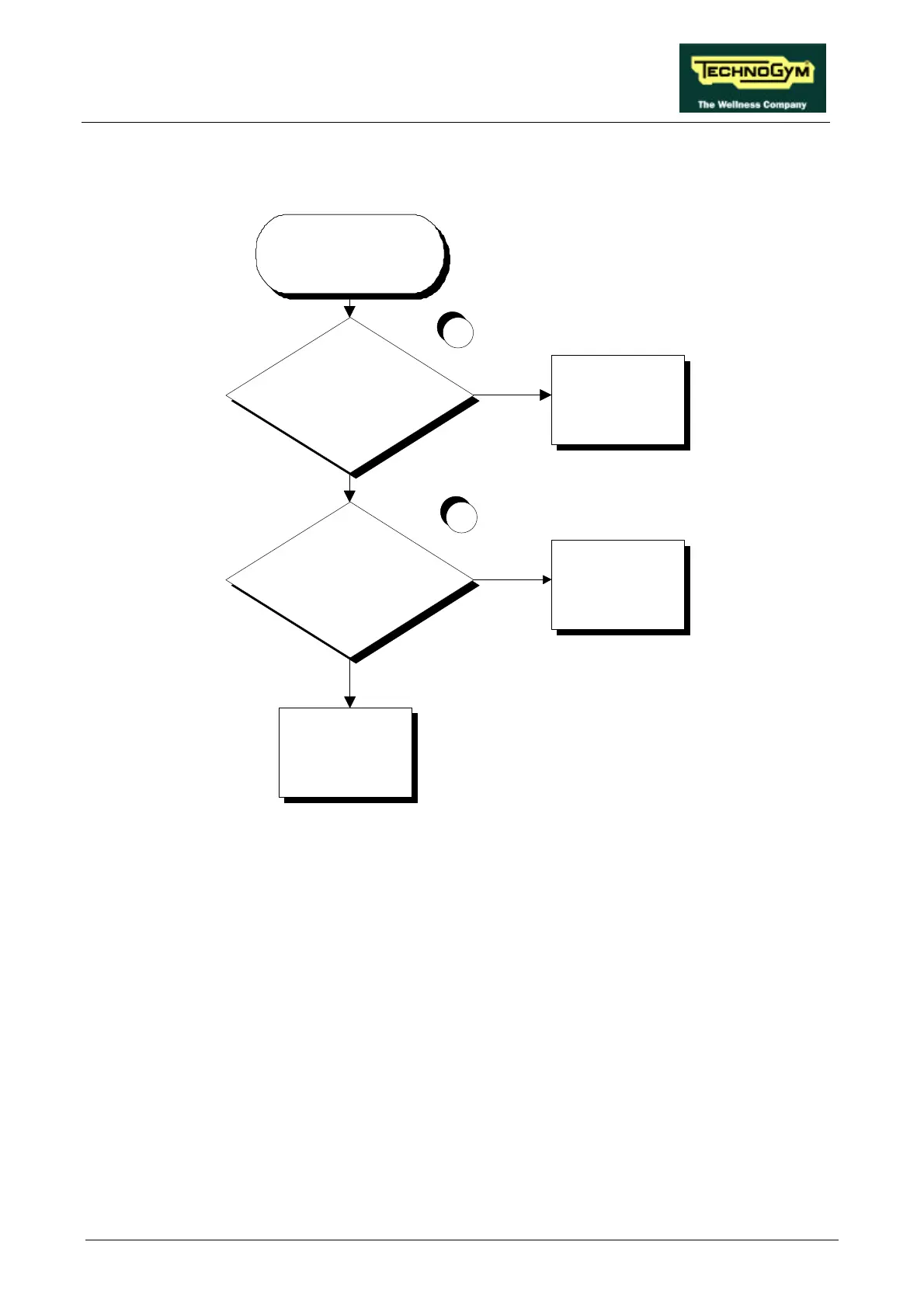

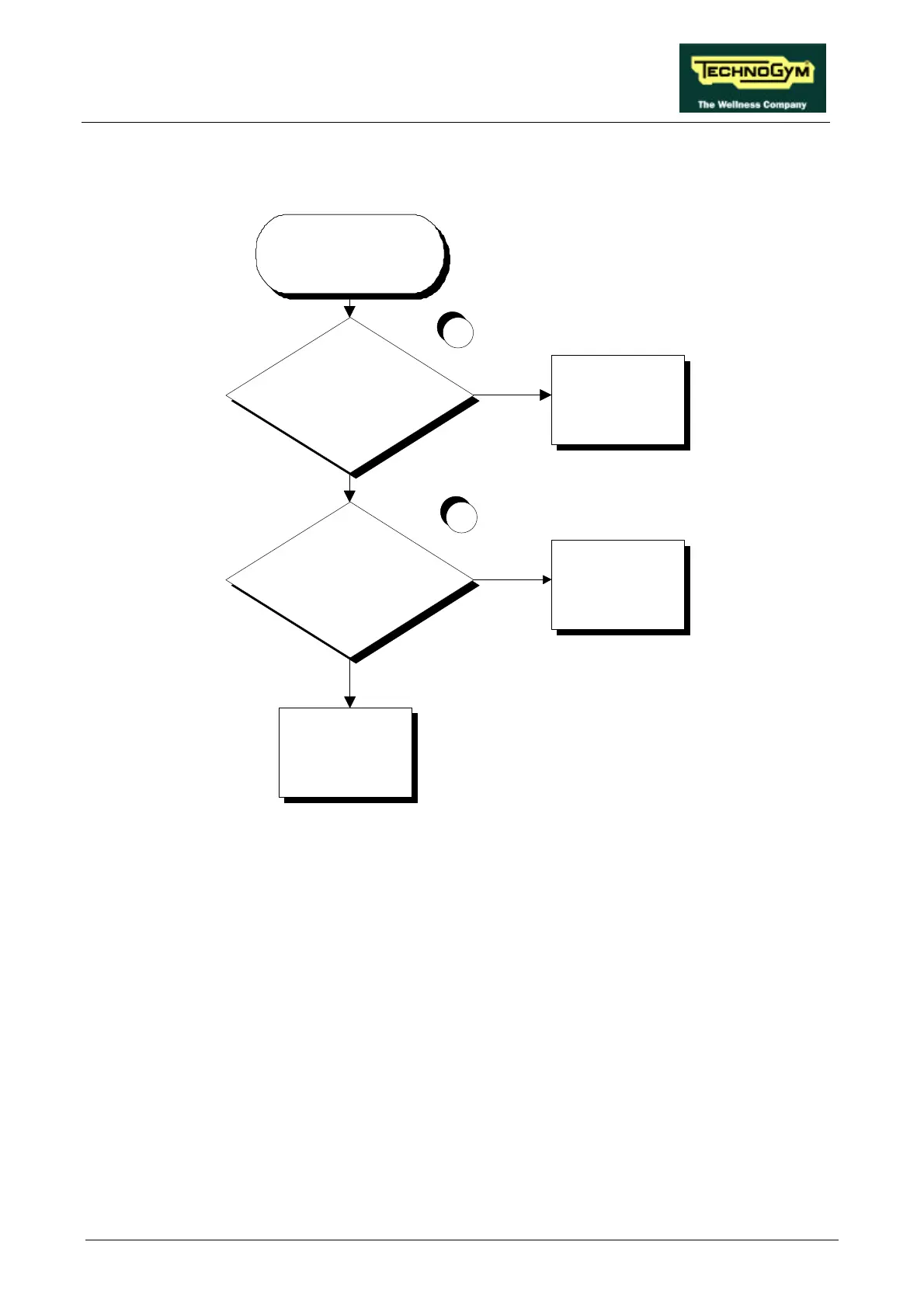

6.5. THE BELT MOTOR STARTS WITH DELAY

THE BELT

MOTOR STARTS

WITH DELAY

Are the Start and Speed PWM

signals correct at the output of the

CPU board?

Are the Start signal and the analog

speed reference signal correct at the

output of the inverter interface

board?

YES

NO

YES

Replace the inverter

interface board: see

paragraph 7.12.

1

2

NO

Replace the inverter: see

paragraph 7.13.

Replace the CPU board:

see paragraph 7.3.

Follow the procedure step by step to correctly diagnose the problem. Take particular care with the

checks highlighted by circled numbers, which are described in detail below:

(1) To check the Start signal, place a tester between pins 7 (signal) and 3 (ground) of connector

CN1 on the CPU board. When the belt is halted the measured voltage should be 0 Vdc,

whereas immediately after pressing the “Start” key on the display the measured voltage should

be 4.5 Vdc. To check the speed PWM signal, place a tester between pins 6 (signal) and 3

(ground) of connector CN1 on the CPU board. When the belt is halted the measured voltage

should be 5 Vdc, whereas immediately after pressing the “Start” key on the display the reading

should rapidly decrease until it reaches a fixed value corresponding to the selected speed. The

variation of the signal must be accompanied by a corresponding variation in the tread belt

speed: see Table 6.6-1 or Table 6.6-2.

(2) To check the Start signal, place a tester between pins 2 (signal) and 1 (ground) of connector

CN1 on the inverter interface board. When the belt is halted the reading should be -24.7 Vdc,

whereas immediately after pressing the “Start” key on the display the measured value should be

-2.7 Vdc. To check the speed PWM signal, place a tester between pins 5 (signal) and 6

Loading...

Loading...