Manual 0-4691 4-11 OPERATION

4

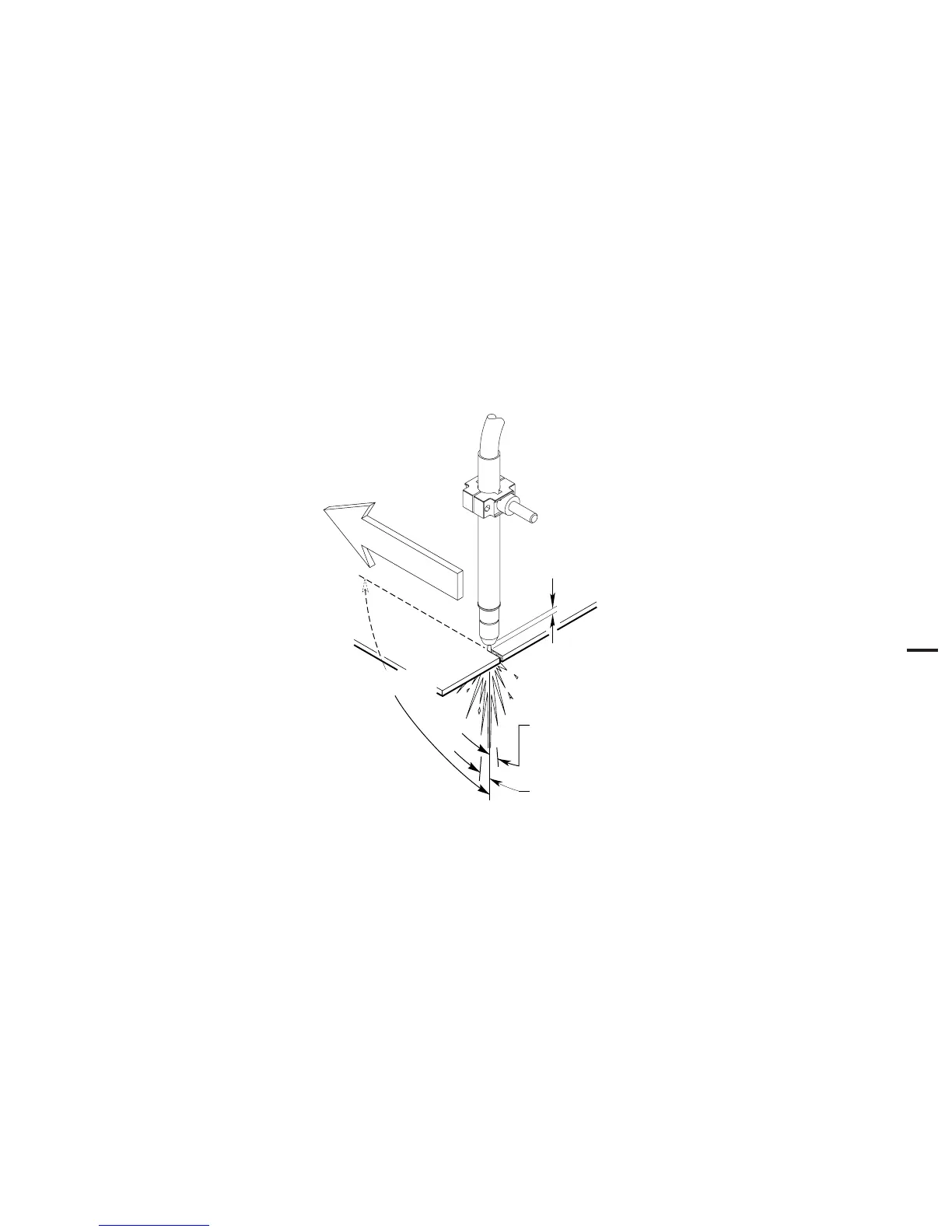

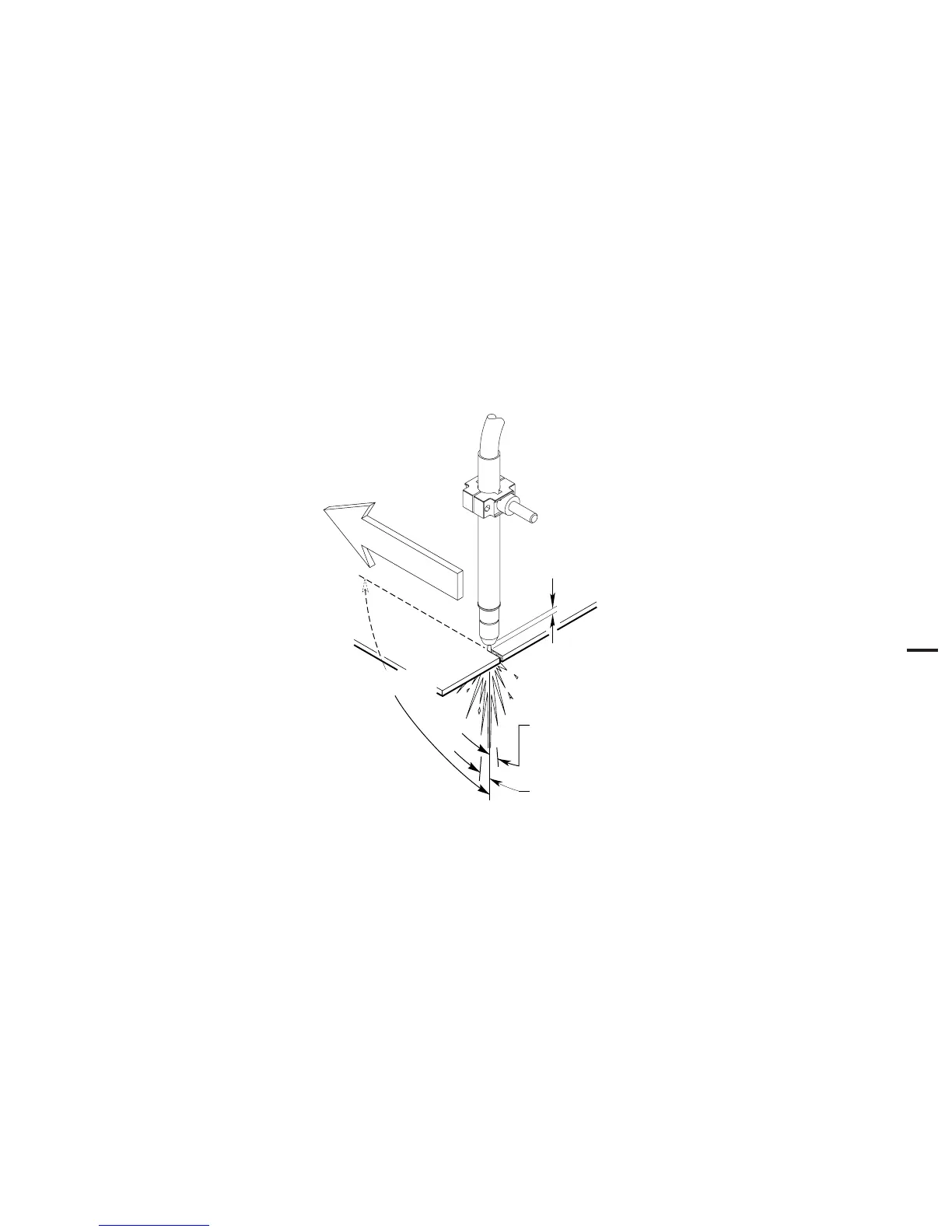

B. Travel Speed

Proper travel speed is indicated by the trail of the arc which is seen below the plate. The arc can be one of the

following:

1. Straight Arc

A straight arc is perpendicular to the workpiece surface. This arc is generally recommended for the best cut

using air plasma on stainless or aluminum.

2. Leading Arc

The leading arc is directed in the same direction as torch travel. A five degree leading arc is generally recom-

mended for air plasma on mild steel.

3. Trailing Arc

The trailing arc is directed in the opposite direction as torch travel.

Standoff Distance

Straight Arc

Trailing Arc

Leading Arc

Direction of Torch Travel

A-02586

Machine Torch Operation

For optimum smooth surface quality, the travel speed should be adjusted so that only the leading edge of the arc

column produces the cut. If the travel speed is too slow, a rough cut will be produced as the arc moves from side to

side in search of metal for transfer.

Travel speed also affects the bevel angle of a cut. When cutting in a circle or around a corner, slowing down the

travel speed will result in a squarer cut.

Loading...

Loading...