Chapter 4 – General Configuration

Firmware Version 3/4.31.37

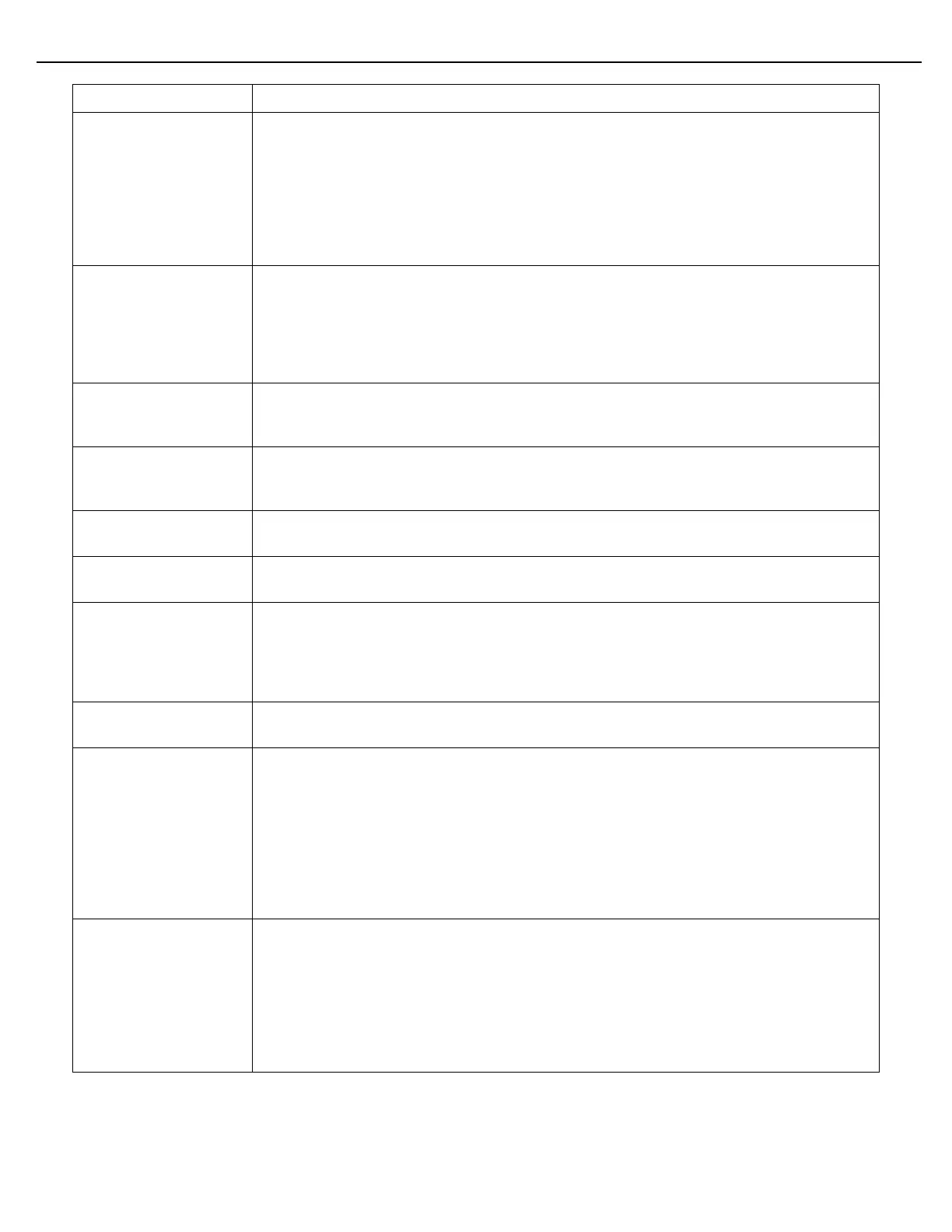

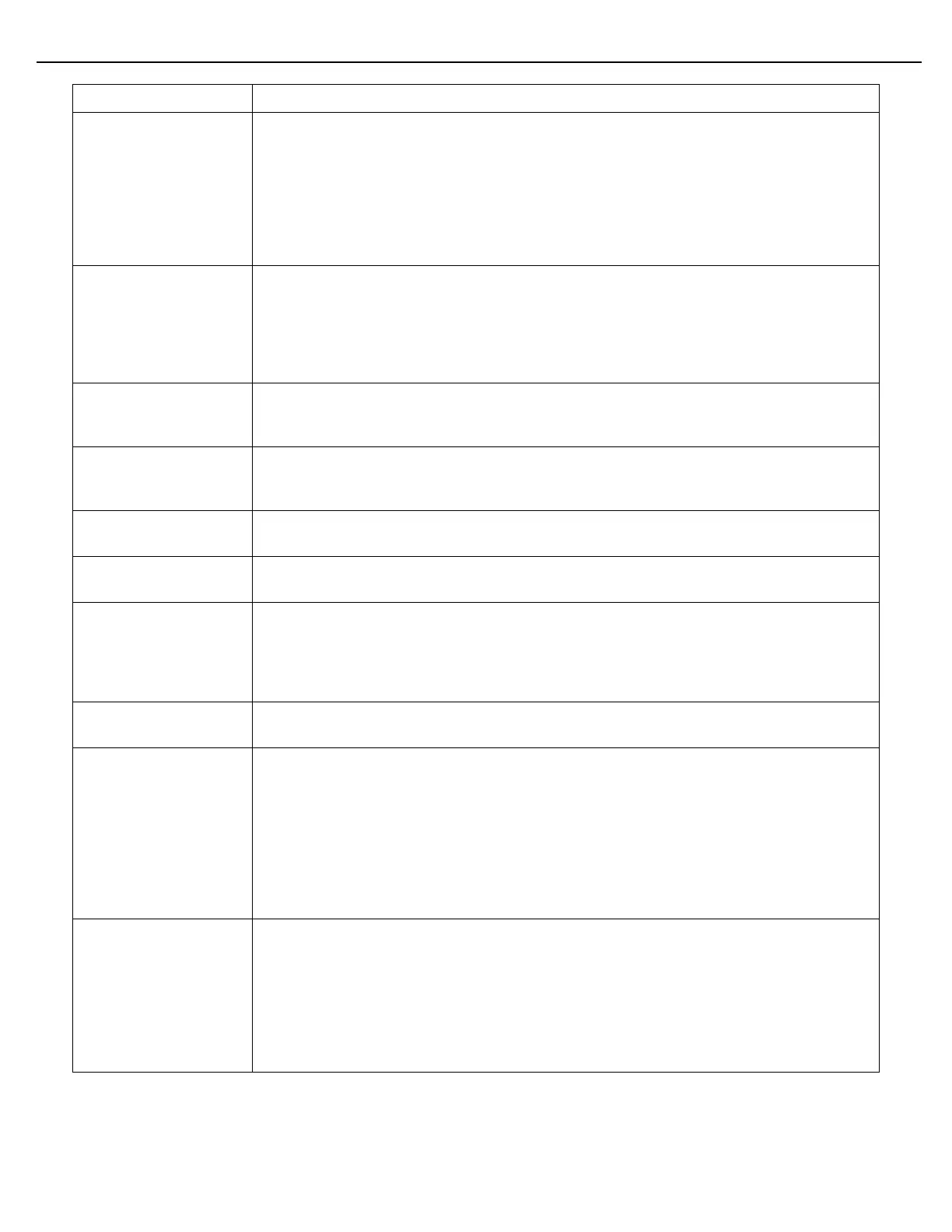

Use this parameter when using hydraulic product selection valves, instead of MOVs. A

value of zero disables this feature. Hydraulic valves used upstream of the digital control

valve may not open fully during the Low Flow stage, due to low differential pressure

across the product selection valve. This may prevent the Block Valve Status input from

signaling that the product selection valve is open, although flow is occurring. Start with a

value equal to the Low Flow Rate minus the Low Flow DB (deadband) Rate. Enter this

value in the Block Valve Open Rate field. Block Valve Open Alarms will not be raised

when the flow rate is below this value.

Set this parameter to delay the opening of a block valve by a period specified in

seconds. When a block valve is employed, it will be commanded open after the delay

time has expired. For the first component of a blend, the delay timer will commence at

the moment that the Start button is pressed. For subsequent components, the timer will

start as soon as flow has stopped for the previous component. Ignore this parameter if

Block Valves are not used.

Specifies the time in seconds to allow the component’s block valve to open. If a

component block valve employs a feedback signal, an alarm will occur if the feedback

requirement is not satisfied in this time.

Specifies the time in seconds to allow the component’s block valve to close. If a

component block valve employs a feedback signal, an alarm will occur if the feedback

requirement is not satisfied in this time.

The starting of the pump will be delayed by the time, in seconds, specified by this

parameter.

After the batch has been completed, the pump will remain on for the period, in seconds,

specified by this parameter.

This alarm setting is used in conjunction with a Pump Status input. If the Pump Status

signal is not received in time specified by this parameter, a Pump Status alarm will be

raised. The time is specified in seconds. Timing will begin as soon as the Start button is

pressed. The setting for this parameter must exceed the setting of the Pump Start Delay

time.

Delays the opening of the flow control valve by a period, in seconds, specified by this

parameter. The delay time begins when the Start button is pressed.

Unauthorized Reset Time. This parameter is intended to prevent nuisance unauthorized

flow alarms for load arms that typically sit idle for long periods of time. Over time, stray

pulses may accumulate and eventually trigger false unauthorized flow alarms in idle load

arms. The value entered here determines how often an internal unauthorized flow alarm

counter gets reset. The internal unauthorized flow alarm counter is not user viewable

and is not to be confused with Unauthorized Flow Totalizers, which do not get reset by

this function. This parameter will reset the internal counter periodically as specified by

the value entered herein to prevent nuisance alarms. Enter a value in seconds. The

possible range of entries is 600-65,535 seconds.

If during the High Flow stage, the flow rate is below the High Flow Deadband Rate for

the period specified by the Fallback Time parameter, the control algorithm will fall back

to the flow rate specified in this parameter. This parameter is intended to be used with

turbine flow meters. When the High Flow rate is unobtainable, the flow rate will revert to

the specified flow rate, which should have a proven meter factor. If the flow meter is a

Positive Displacement (PD) meter, set this parameter to zero and review the Fallback

Time parameter. After specifying a Fallback Rate for a turbine meter application,

configure Fallback Time, Fallback Retry Time and Fallback Retry Volume.

Loading...

Loading...