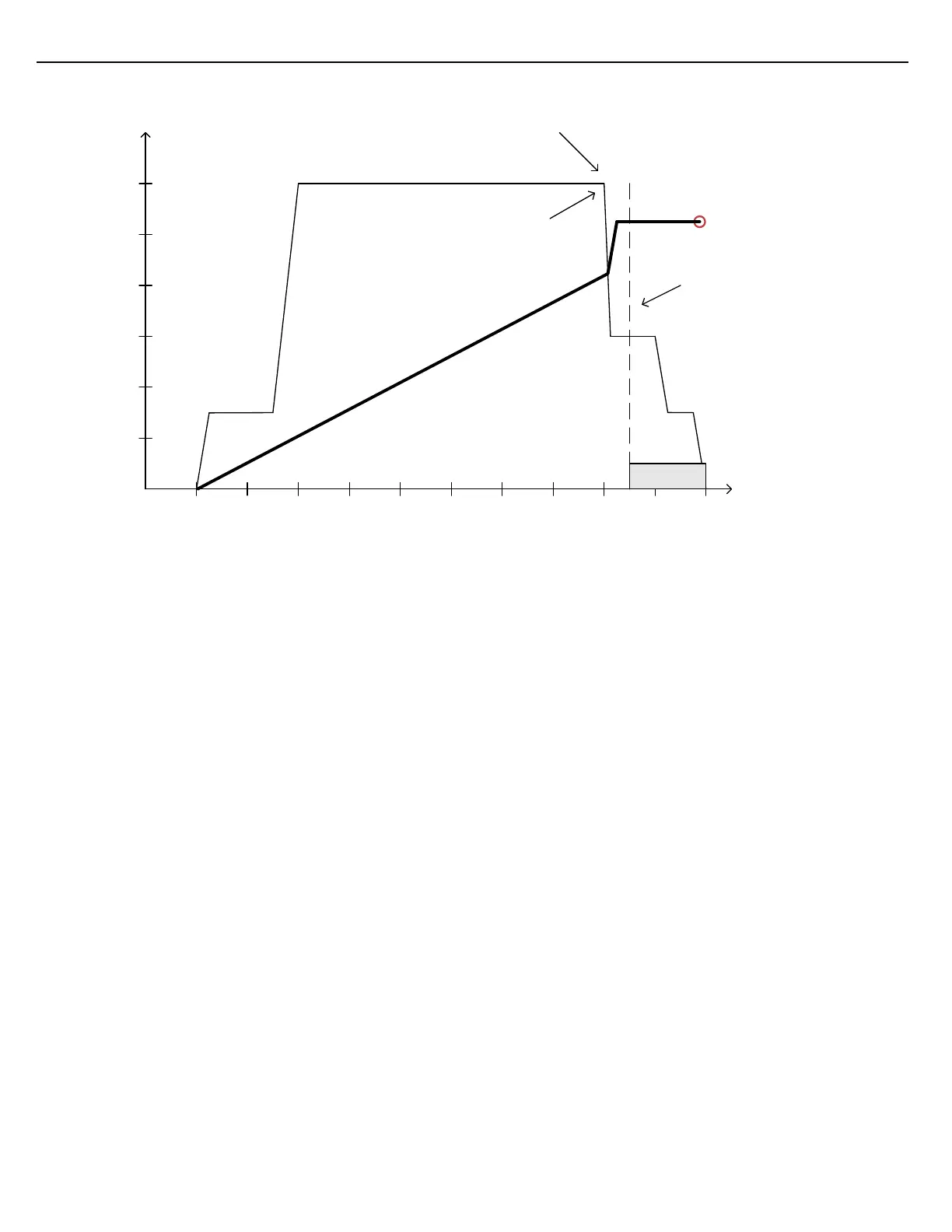

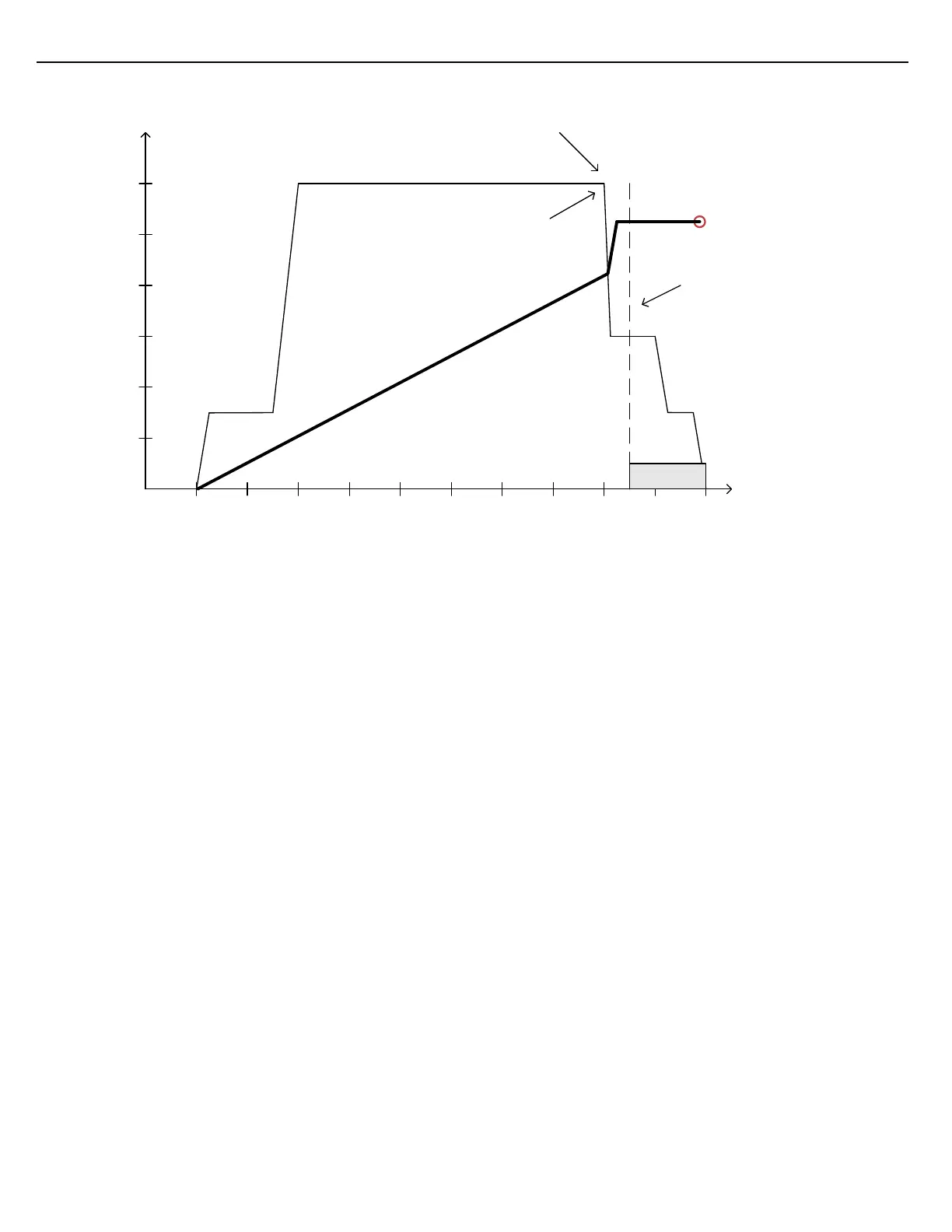

Figure 6.9 Basic Flush Cycle

Last Injection Volume From End-This parameter serves as a warning to the system, that a point is approaching

where all additive for the load must be delivered. Determine the volume that exists between the injection point

and the end of the load arm. If the 1

st

Trip Stage Volume is several times the volume that exists between the

injection point and the end of the load arm, enter a value that is equal to the 1

st

Stage Trip Volume. When the

load’s remaining volume is equal to the Last Injection Volume From End, the system will begin its final injection to

finish the additive demand of the load. This parameter should be set to a number that is higher than the volume

specified in the Shutoff Volume From End parameter.

Shutoff Volume From End-When the volume remaining in the load reaches the value entered for Shutoff

Volume From End, additive delivery will cease, regardless of the demand that is remaining. If the Shutoff Volume

From End parameter is set to 150 gallons, additive delivery will stop when there is 150 gallons to be delivered.

The remaining product volume will flush additive from the line.

Line Flush Min Vol-Set this parameter to ensure that the minimum required flush volume is delivered. If the load

is aborted before enough product has flushed the line, an Additive Flush alarm will activate, warning that the flush

may be insufficient.

Throughout most of the delivery cycle, the additive/product ratio will be within the specified recipe. When the final

injection occurs, prior to reaching the volume specified by Shutoff Volume From End, the load will be slightly over

additized. By the time the load is complete the additive/product ratio will be on target.

Loading...

Loading...