Chapter 9 – Weights & Measures

Firmware Version 3/4.31.37

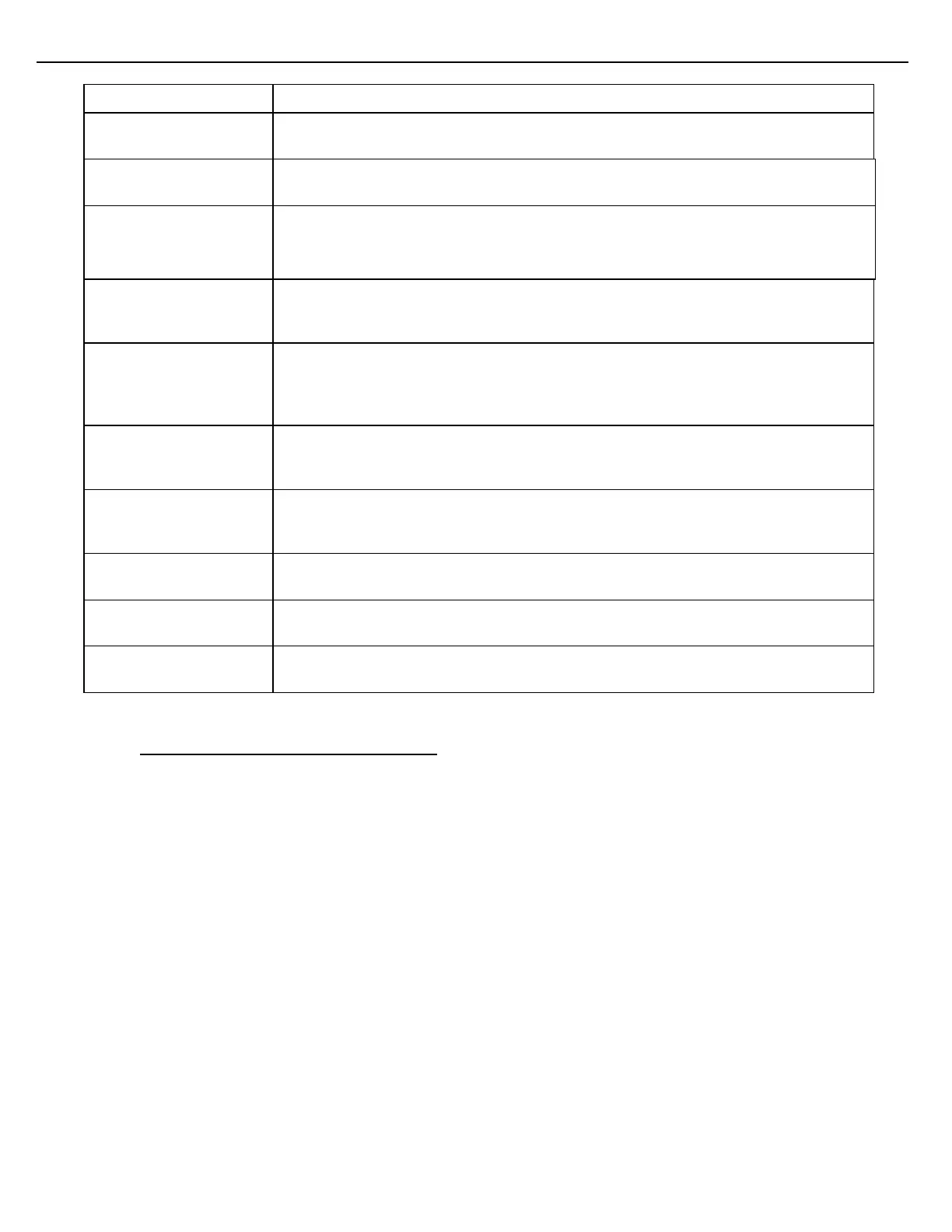

Select the desired API table to correct liquid volumes to a reference temperature.

Highlight the field and press Enter to scroll through the choices.

Enter a test temperature in this field. The temperature that is entered here will not

have any effect on actual measurement.

Test Density or

Test Relative Density or

Test API Gravity

Enter a test density, test relative density or test API Gravity in this field. The value

that is entered here will not have any effect on actual measurement.

API Gravity/Expansion

Coefficient

One of these fields will appear, depending on the API table selected. Enter the

requested value in this field. The value that is entered in this field will be used to

calculate VCF during operations.

The value in this field is the result of the API Test Temperature and the data in the

previous field (density, gravity, or expansion coefficient). This Calculated VCF is for

information only and has no affect on actual measurement. VCF is equal to CTL *

CPL.

The value in this field is the result of the API Test Temperature and the data in the

previous field (density, gravity, or expansion coefficient). This Calculated VCF is for

information only and has no affect on actual measurement.

The value in this field is the result of the API Test Temperature and the data in the

previous field (pressure). This Calculated VCF is for information only and has no

affect on actual measurement.

Corrected Relative

Density

This field will appear, depending on the API table selected. The value will show the

corrected Relative Density.

This field will appear, depending on the API table selected. The value will show the

corrected Density.

This field will appear, depending on the API table selected. The value will show the

corrected Gravity.

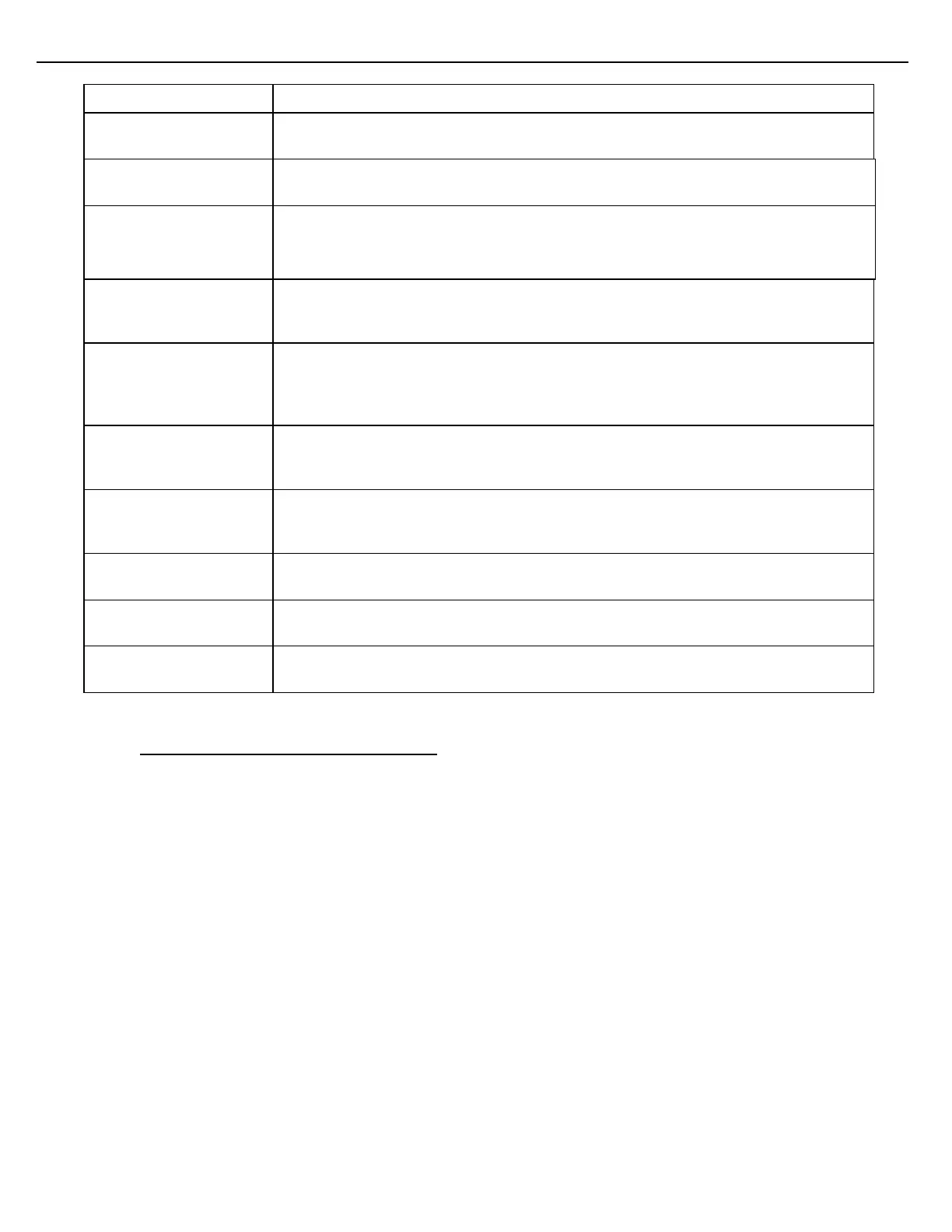

9.15 PRESSURE CALIBRATION FOR METERS

Use the Pressure screen to calibrate pressure for a meter.

1. From the Views & Inquiries Menu, choose Pressure.. After selecting the preset and meter, the Pressure

screen displays:

Loading...

Loading...