Chapter 5 – Product Flow Control

Firmware Version 3/4.31.37

short the first component in the recipe; the first component will be shorted by the Line Flush Volume. If this

parameter is disabled, MultiLoad will look to the third decision parameter.

The third decision parameter is Take Line Flush From Last. This parameter must be enabled if the two previous

parameters are disabled. MultiLoad will subtract the Line Flush Volume from the last component in the recipe.

The preset quantity will be satisfied by the Line Flush Component during the Line Flush stage.

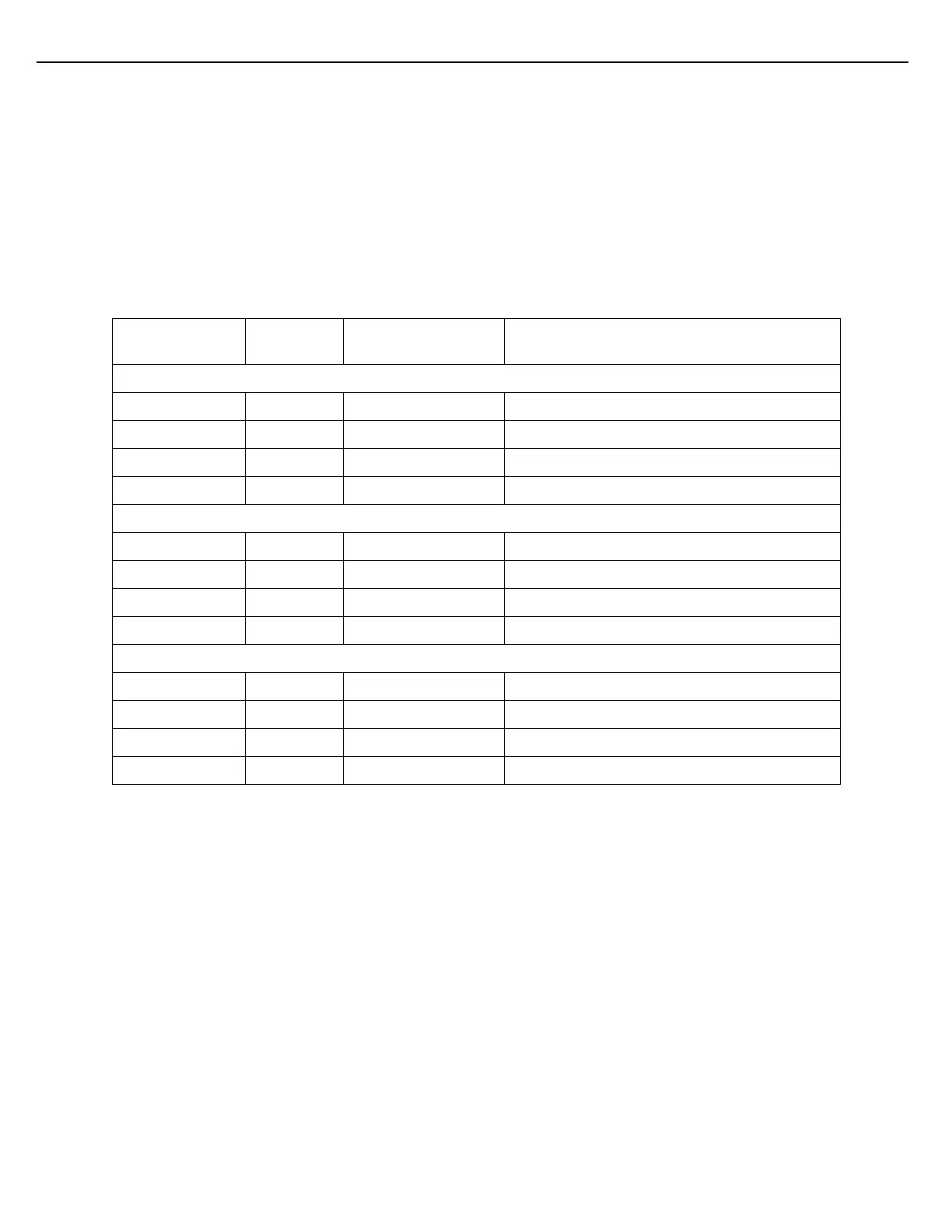

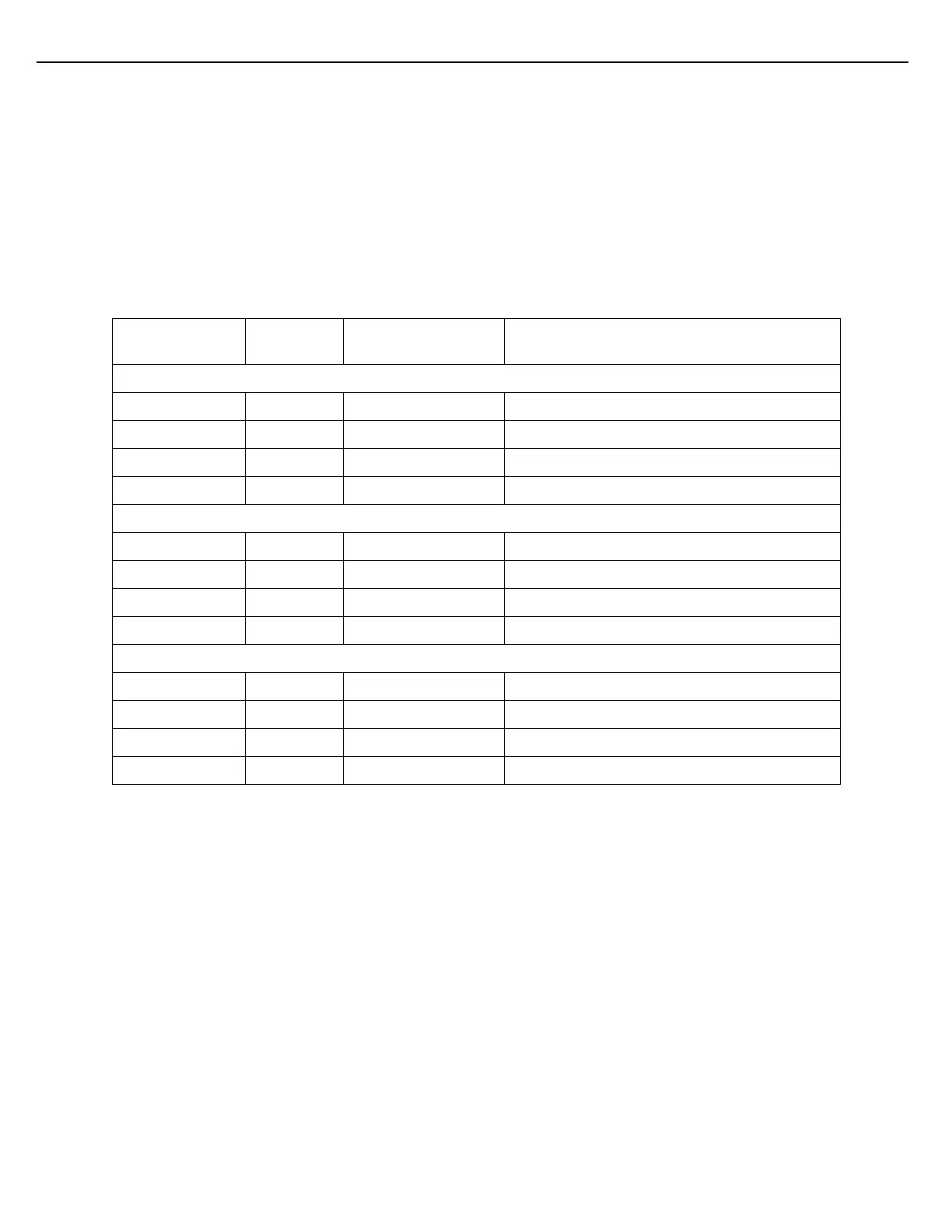

Example

The following table shows how a 1000 gallon load is affected by each of the decision parameters. The product is

a 60/40 blend. Component #1 is 60% of the total, and component #2 is 40% of the total. The Line Flush

Component is component #1. The Line Flush Volume is 100 gallons.

Take Flush from Matching Component

Line Flush Component is component #1

Take Flush From First Component

Line Flush Component is component #1

Take Flush From Last Component

Line Flush Component is component #1

In Example 1, using Take Flush From Matching Component results in a 60/40 blend. The first component is

shorted by 100 gallons, but it is made up at the end of the load, since the first component is also the flush

component.

Example 2 produces identical results. The MultiLoad will short the first component in the product recipe, which

happens to be the designated flush component.

In Example 3, when the Take Flush From Last Component is executed, the resulting product ratio is 70/30. The

last component (component #2) is shorted by 100 gallons and the preset quantity is satisfied by flush component,

which is component #1. The desired 60/40 result would have been achieved in this case if component #2 had

been designated as the Line Flush Component.

Loading...

Loading...