Chapter 13 – Custom Logic

Firmware Version 3/4.31.37

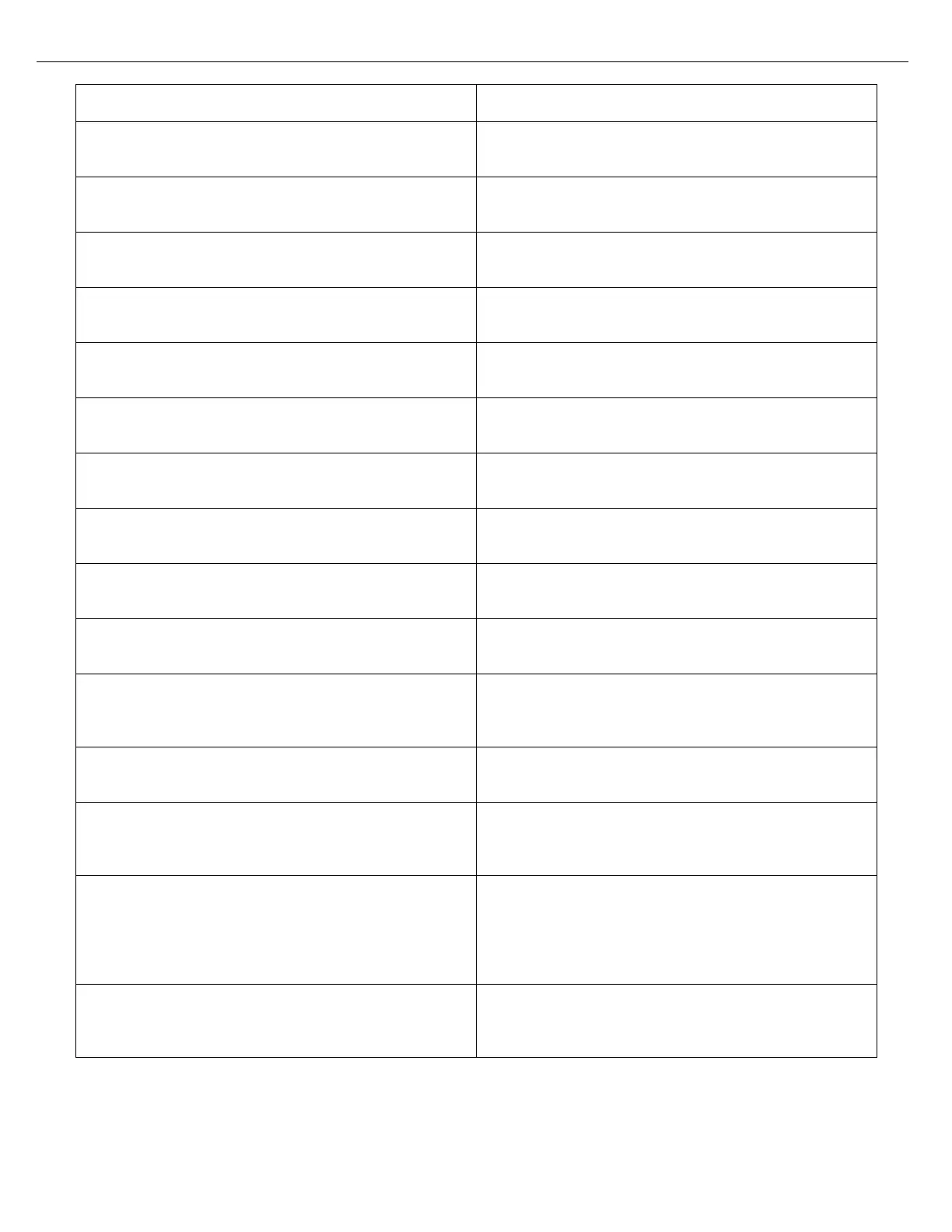

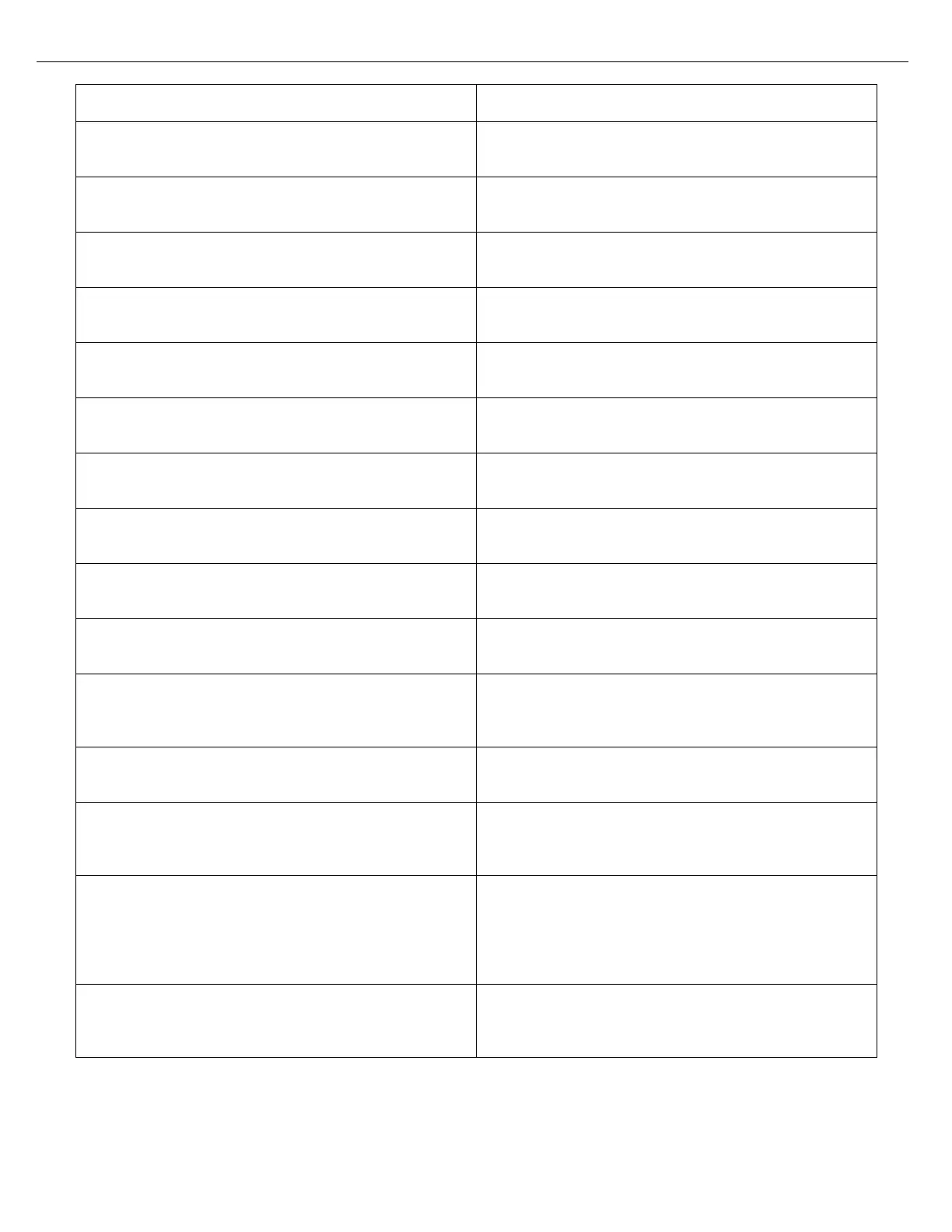

Indicates that a Pump Kill signal has been received for

a particular additive.

Indicates that a Pump Status signal has been satisfied

for a particular additive.

Indicates that a Block Valve has been commanded to

open for a particular additive.

Indicates that an additive-level Block Valve status has

been received from a particular additive.

Indicates that a particular additive’s Flush Pump has

been commanded to run.

Indicates that a Block Valve has been commanded to

close for a particular additive.

Indicates that an additive-level alarm, such as Injector

Fault, is active for a particular additive.

Indicates when a driver is authorized to use a particular

additive.

Indicates that an additive-level permissive has been

received.

Indicates that all additive-level permissives have been

satisfied.

The gross volume that has been delivered, of the

specified additive, for the current batch. Value is in

thousandths with an inferred decimal.

The percentage, of the specified additive, as defined in

the current product recipe.

The current target gross volume for the current batch

being loaded. Value is in thousandths with an inferred

decimal.

The current gross volume, of the specified additive, for

the current batch. The value is computed using the

actual volume delivered along with the percentage

defined in the recipe, and is displayed in thousandths

with an implied decimal.

The current amount of volume remaining that is needed

to flush the line of the specified additive. Value is in

hundredths with an implied decimal.

Loading...

Loading...