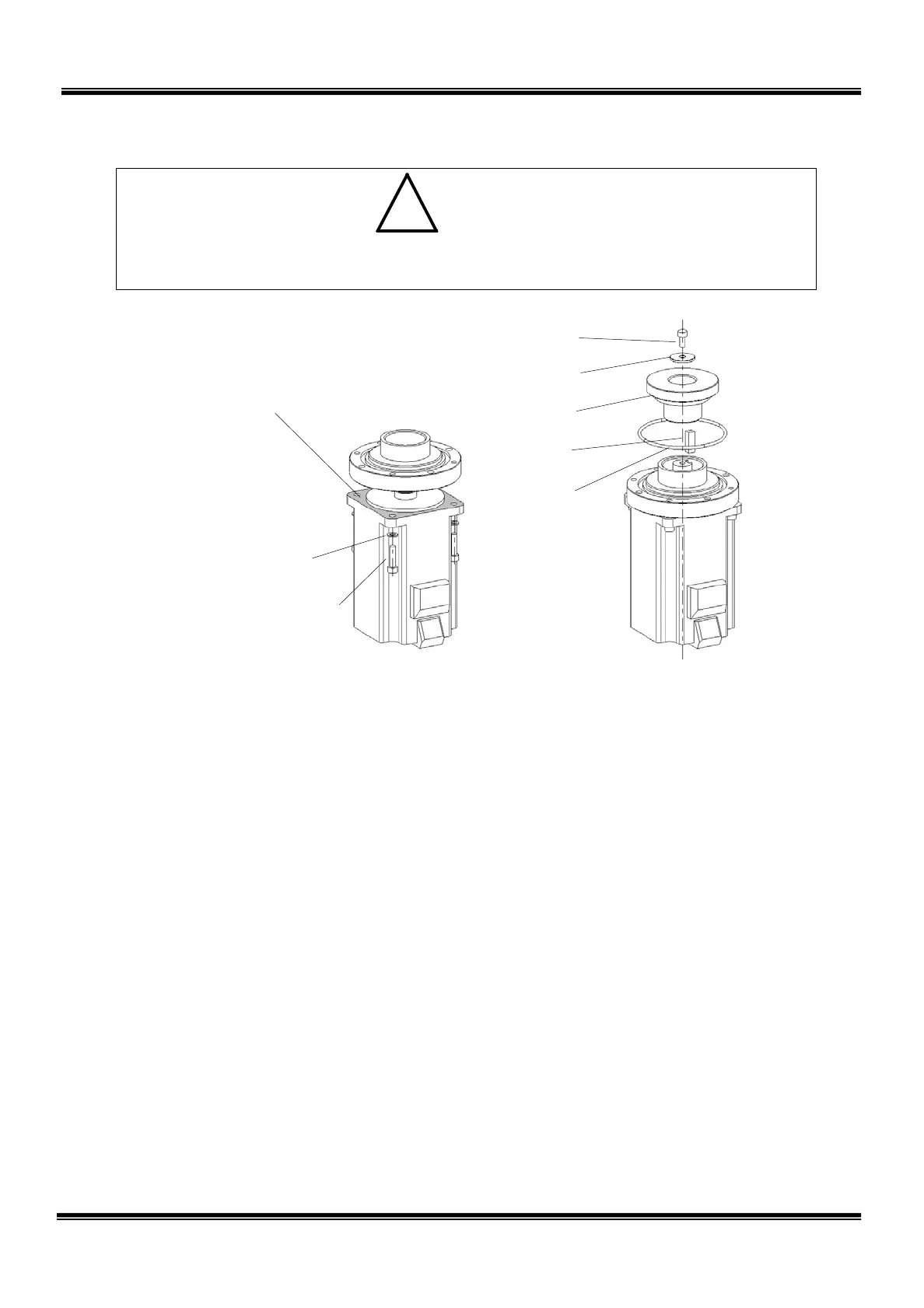

clamping torque: 8.8 N·

M5x10 (Recommended clamping torque: 8.8 N·m)

Surface where liquid

gasket is to be applied.

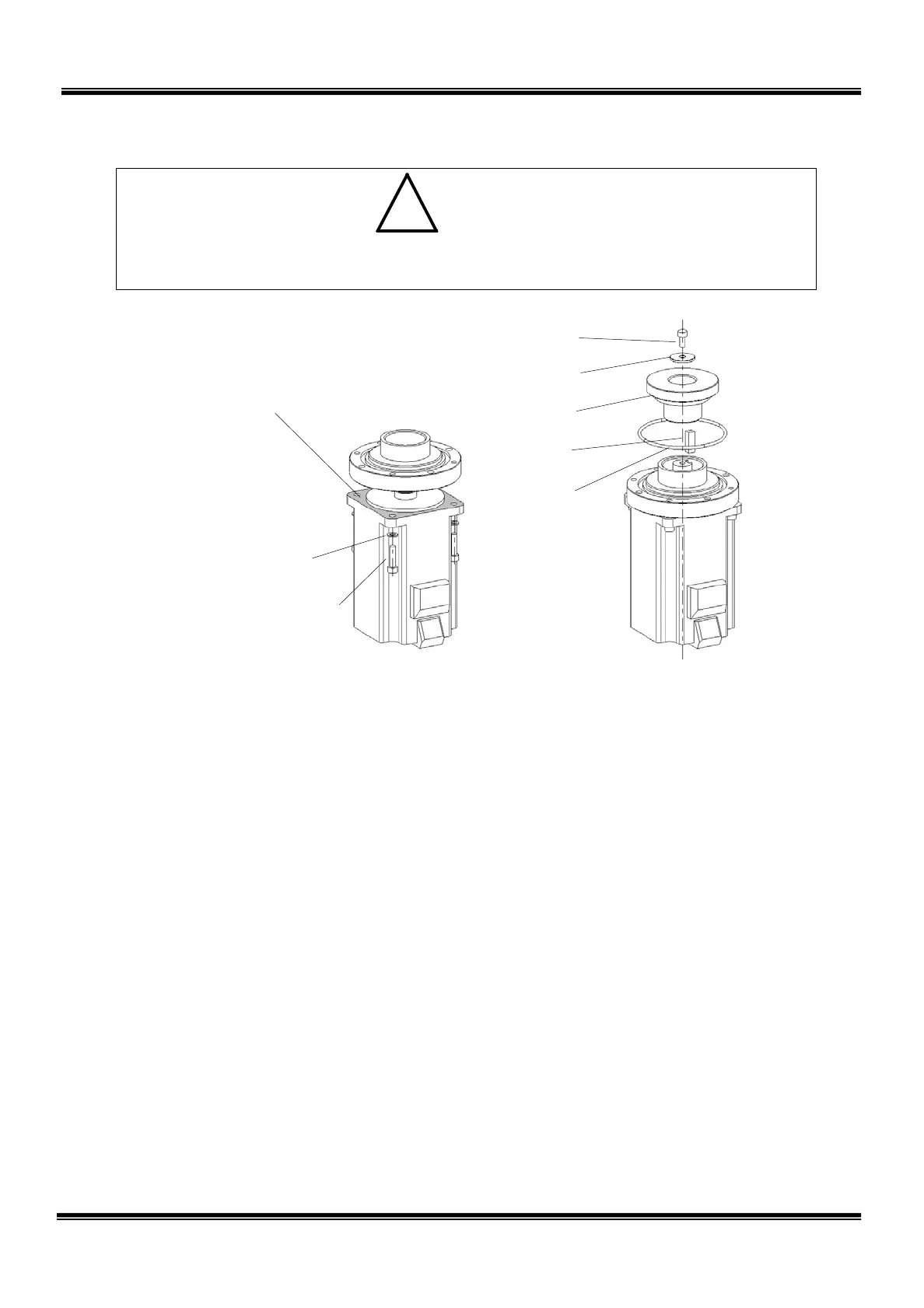

• When mounting the input gear, DO NOT knock it with excessive force.

Otherwise, the encoder may be damaged.

4) Set the “O” ring in the “O” ring groove of the motor base to secure it to the base.

5) To secure the “O” ring set in the “O” ring groove of the motor base, follow the

steps in Para. 2.5.3 in the reversed order.

6 Connect the axis 1 motor connectors (for the power drive cable and encoder

cable).

7) Return the cables in the base as originally arranged, then attach the cover to

the base.

8) After the axis 1 motor is replaced with a new one and before the power is turned

on, move the arm 1 by hand to make sure that no abnormal noise is heard.

9) Turn the power on and perform home setting for the axis 1. Now, the motor

replacement completes.

(Check for the coordinates of the axes 2, 3 and 4, and perform home setting

when necessary.)

STE 85306

– 34 –

Loading...

Loading...